Crosslinking of polyaryletherketones

A technology of polyaryletherketone and crosslinking agent, which is applied in the field of crosslinking of polyaryletherketone, and can solve problems such as high environmental pollution and user hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

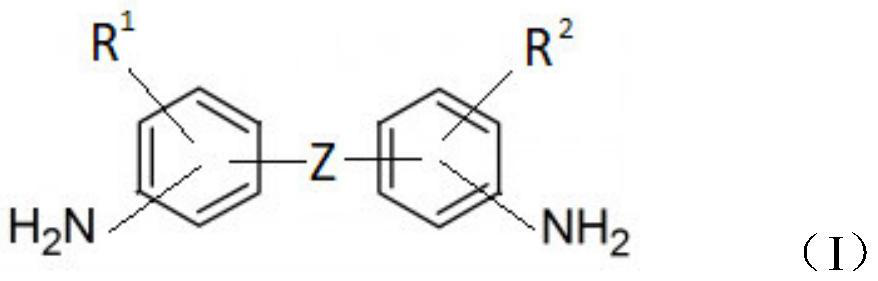

[0096] Mixtures were prepared as shown in Table 1. According to Thompson and Farris, 1988, amine-functionalized PEEK (hereinafter referred to as "AF-PEEK") was prepared using PEEK and p-phenylenediamine, and ground into powder. The total nitrogen content was determined according to the Kjeldahl method, and the conversion rate of PEEK carbonyl group was 95%. DAPI with a purity of 98% (CAS No. 54628-89-6) was used as a crosslinker.

[0097] Table 1: Mixtures

[0098] instance number compounding 1 (control) PEEK 2 (control) PEEK, 4 wt% AF-PEEK 3 PEEK, 1.05 wt% DAPI

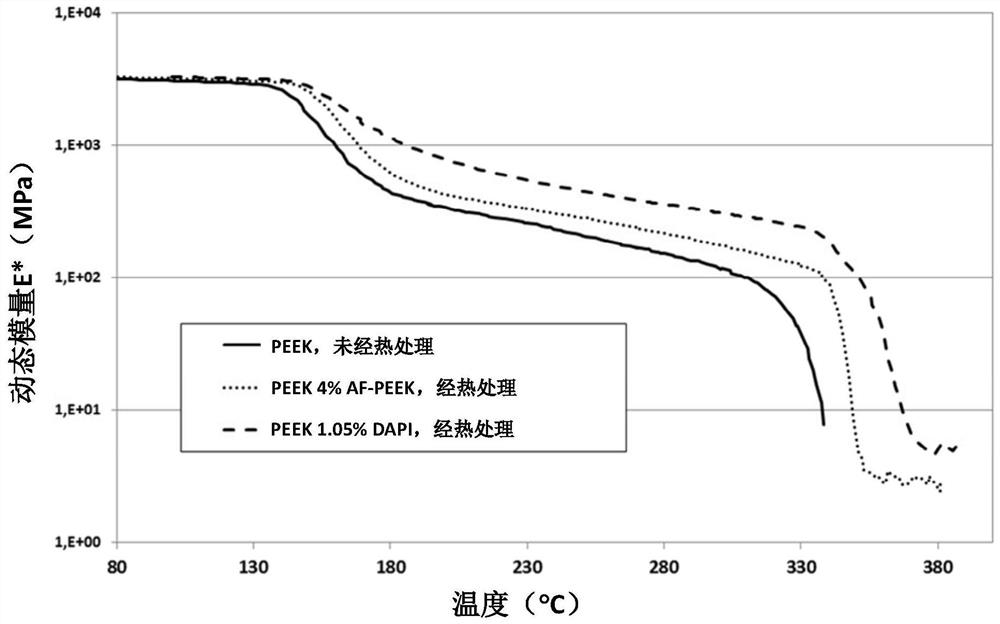

[0099] The mixtures in Table 1 were processed into test specimens in injection molding and then heat treated to crosslink.

[0100] Table 2: Heat treatment and tensile elongation test results

[0101]

[0102] Tensile tests were carried out at 240° C. according to standard DIN EN ISO 527-2.

[0103] The results show that the samples according to the invention become in...

Embodiment 2

[0111] As in previous Example 1, the DAPI isomer mixture (crosslinker of formula VI) of Chemical Abstracts Service CAS No. 68170-20-7 was mixed into medium viscosity commercial PEEK by twin-screw compounder, and the The strands are chopped into granules.

[0112] Table 3: Mixtures

[0113]

[0114]

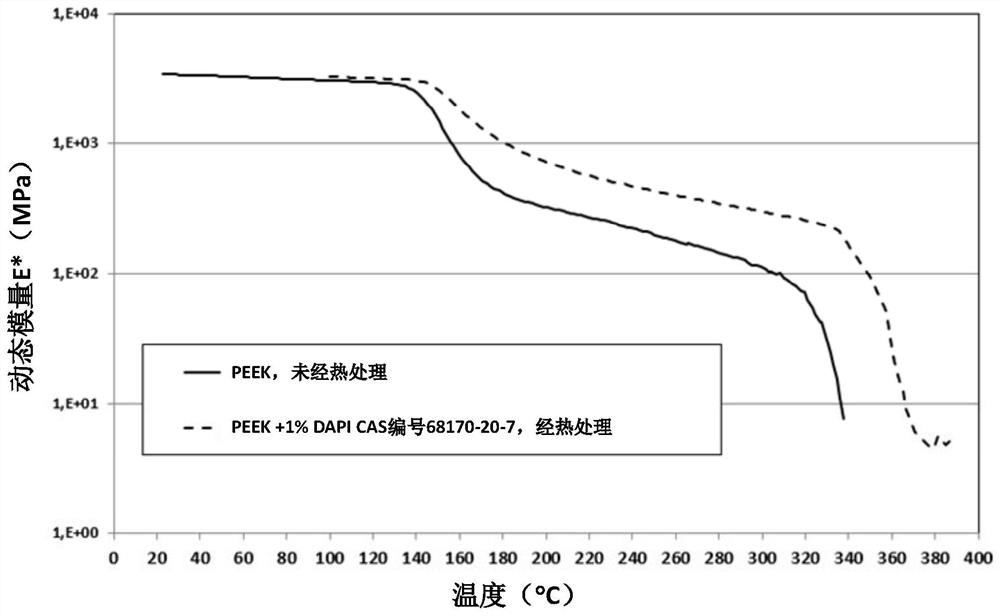

[0115] Pellets from the mixtures of Table 3 were processed into test specimens in injection molding and then also subjected to a thermal aftertreatment. Test specimens in T-scans by means of DMA according to Example 1, thus obtaining figure 2 The results shown.

[0116] figure 2 Shown is article 4 (PEEK with 1% DAPI (CAS No. 68170-20-7, heat-treated, dashed curve) compared to standard base material 1 (non-heat-treated PEEK, solid line), according to the invention Evolution of the molded complex dynamic modulus with increasing temperature.

[0117] Here, refer to figure 1 The advantageous results discussed are also obtained in a similar fashion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com