Thermoplastic high-viscosity high-elasticity asphalt modifier for pavement on steel bridge surface and preparation method thereof

A technology of asphalt modifier and thermoplastic elastomer, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of poor high temperature resistance, cracking, etc., and achieve the effects of improving fluidity, simple preparation process, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

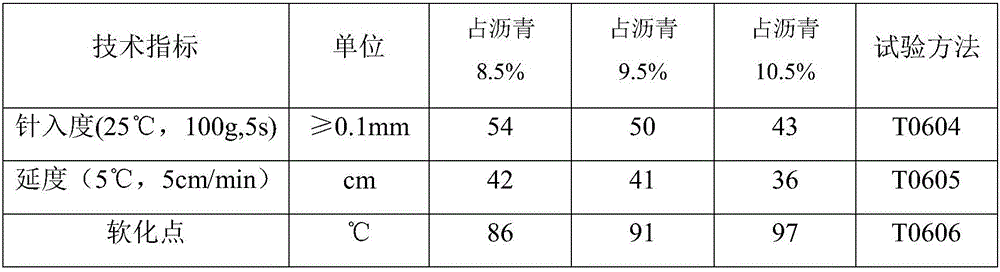

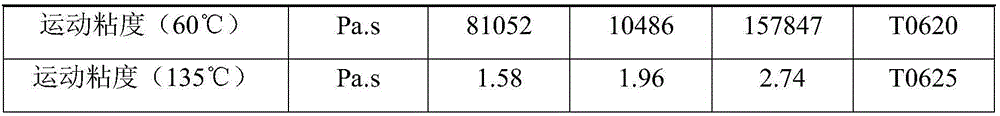

Examples

Embodiment 1

[0030] The thermoplastic high-viscosity and high-elasticity asphalt modifier used for steel bridge deck pavement is composed of 57% thermoplastic elastomer, 3% PE, 35% petroleum resin, and 5% furfural oil.

[0031] Add thermoplastic elastomer, PE, petroleum resin, and furfural extract oil into the strands of the screw extruder to granulate, and the extrusion temperature is controlled at 120°C.

Embodiment 2

[0033] Thermoplastic high-viscosity and high-elasticity asphalt modifier for steel bridge deck pavement, its weight percentage is composed of: thermoplastic elastomer 49%, PE 15%, petroleum resin 15%, diatomite roasted product 25%, furfural extraction Oil 5%, auxiliary agent 6%.

[0034] Add thermoplastic elastomer, PE, petroleum resin, diatomite roasted product, furfural extraction oil, and additives into the strands of the screw extruder to granulate, and the extrusion temperature is controlled at 200°C.

Embodiment 3

[0036] Thermoplastic high-viscosity high-elasticity asphalt modifier for steel bridge deck pavement, its weight percentage is composed of: thermoplastic elastomer 52%, PE 10%, petroleum resin 15%, furfural oil 20%, auxiliary agent 3% .

[0037] Add thermoplastic elastomer, PE, petroleum resin, furfural oil, and additives into the strands of the screw extruder to granulate, and the extrusion temperature is controlled at 180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com