Preparation method of friction-reducing and wear-resistant hypereutectic aluminum-silicon alloy based on rare earth cerium modification

An aluminum-silicon alloy and rare-earth cerium technology is applied in the field of preparation of a new type of friction-reducing and wear-resistant hypereutectic aluminum-silicon alloy, which can solve the problems of inability to meet the friction and wear properties of the alloy, reduce the wear resistance of the alloy, etc., so as to improve the friction environment, The effect of increasing the degree of supercooling and enhancing the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

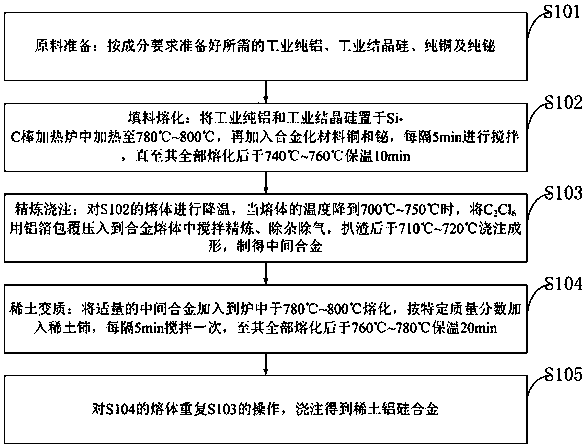

[0021] Such as figure 1 As shown, the method for preparing a novel friction-reducing and wear-resistant hypereutectic aluminum-silicon alloy based on the modification of rare earth cerium provided by the embodiment of the present invention, the specific steps include:

[0022] S101: Raw material preparation: Prepare the required industrial pure aluminum, industrial crystalline silicon, pure copper and pure bismuth according to the composition requirements;

[0023] S102: Filler melting: put industrial pure aluminum and industrial crystalline silicon in a Si-C rod heating furnace and heat to 780°C~800°C, then add alloying materials copper and bismuth, and stir every 5 minutes until they are completely melted Insulate at 740°C~760°C for 10 minutes;

[0024] S103: Refining pouring: cool down the melt of S102, when the temperature of the melt drops to 700°C~750°C, put C 2 Cl 6 Wrap it with aluminum foil and press it into the alloy melt to stir and refine, remove impurities and ...

Embodiment 1

[0031] (1) Add aluminum ingots and industrial crystalline silicon into a Si-C rod crucible furnace with a furnace temperature of 780°C~800°C. After they are completely melted, add pure copper and pure bismuth, stir every 5 minutes, and 740°C~760°C for 10 minutes; (2) When the melt temperature drops to 700°C~750°C, put the aluminum foil wrapped C 2 Cl 6 Press into the melt to stir and refine, remove impurities and slag; (3) When the temperature of the melt drops to 710°C~720°C, pour the melt into a metal mold to solidify and form, and prepare Al-17Si-3Cu-2Bi Master alloy; (4) Melt the master alloy prepared in step (3) in a crucible boiler at 780°C to 800°C, then add rare earth cerium with a mass fraction of 0.2% to the alloy melt, and stir once every 5 minutes, And heat preservation and deterioration at 760°C~780°C for 20min; (5) Repeat the operation process of step (2) and step (3) to prepare a new anti-friction and wear-resistant hypereutectic aluminum-silicon alloy based on...

Embodiment 2

[0033] Repeat the steps (1) (2) (3) in Example 1 to obtain the master alloy of Al-17Si-3Cu-2Bi, and then melt the master alloy in a crucible boiler at 780 ° C ~ 800 ° C, adding a mass fraction of 0.6% Rare earth cerium is modified, adopt the same modification temperature and holding time as step (4) in Example 1, and cast it when the melt temperature drops to 710 ° C ~ 720 ° C, and prepare a new type of anti-friction and wear resistance based on rare earth cerium modification Hypereutectic Al-Si alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com