Polyphenylene sulfide-based self-lubricating multi-component composite material and preparation method thereof

A technology of polyphenylene sulfide and composite material is applied in the field of polyphenylene sulfide-based self-lubricating multi-component composite material and its preparation, so as to avoid direct scratching, have broad application prospects and improve wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

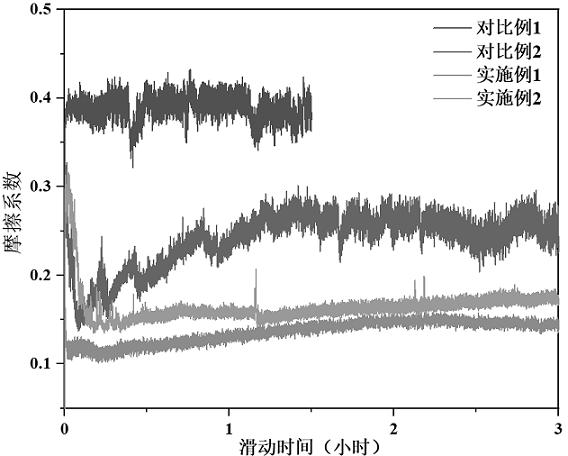

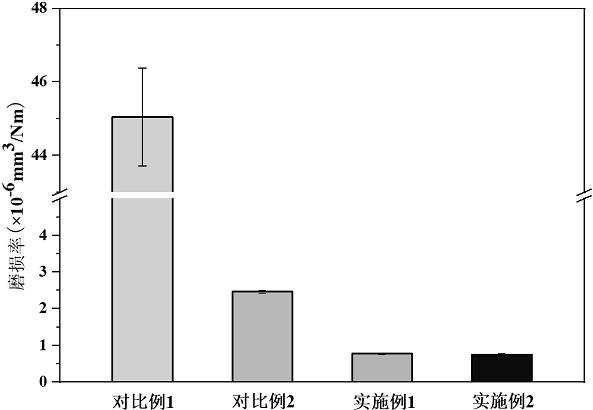

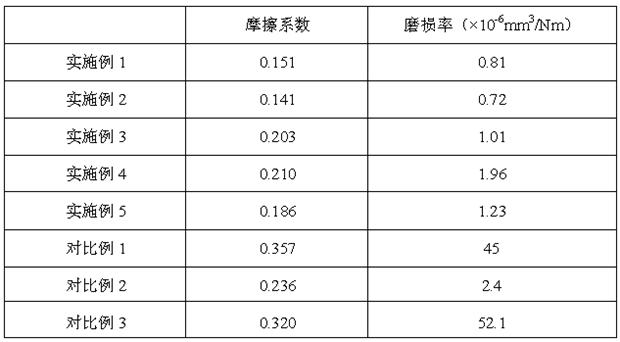

Examples

preparation example Construction

[0024] The preparation method of the composite material: firstly weigh each raw material according to the ratio; then dry each raw material at 120°C for 5h to 12h; secondly, dry the dried nano-scale serpentine, reinforced fiber, polyphenylene sulfide powder or The granules and or solid lubricants are fully mixed with a high-speed mixer, or melted and blended with a twin-screw extruder and extruded to granulate; finally, the obtained mixed powder or granules are hot-pressed or injected to obtain a compound Material.

[0025] The working conditions of the twin-screw extruder refer to the heating temperature of the first zone 320°C~325°C, the heating temperature of the second zone 330°C~335°C, the heating temperature of the third zone 340°C~345°C, the heating temperature of the fourth zone 350°C~355°C, The mold temperature is 130°C~150°C, the injection pressure is 50MPa, the screw speed is 40rpm~150rpm, and the back pressure is 1MPa~4MPa.

Embodiment 1

[0026] Example 1 A polyphenylene sulfide-based self-lubricating multi-component composite material

[0027] Put 85L of polyphenylene sulfide matrix, 10L of carbon fiber, and 5L of serpentine in an oven for drying, drying for 5 hours at a drying temperature of 120°C; then use a twin-screw extruder to melt, blend and extrude them Granulation and injection molding; among them, the heating temperature of the first zone of the twin-screw extruder is 320~325℃, the heating temperature of the second zone is 330℃~335℃, the heating temperature of the third zone is 340℃~345℃, and the heating temperature of the fourth zone is 350℃~ 355°C, mold temperature of 150°C, injection pressure of 50MPa, screw speed of 150rpm, and back pressure of 1MPa.

Embodiment 2

[0028] Example 2 A polyphenylene sulfide-based self-lubricating multi-component composite material

[0029] 80L of polyphenylene sulfide matrix, 10L of carbon fiber, 2L of serpentine and 8L of graphite were dried in an oven for 12 hours at a temperature of 120°C; they were melt-blended and extruded using a twin-screw extruder Extrusion granulation, injection molding; twin-screw extruder heating temperature of zone 1 is 320℃~325℃, heating temperature of zone 2 is 330℃~335℃, heating temperature of zone 3 is 340℃~345℃, heating temperature of zone 4 is 350℃~355 °C, the mold temperature is 130 °C, the injection pressure is 50 MPa, the screw speed is 40 rpm, and the back pressure is 1 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com