A carbon-containing high-entropy alloy material and its preparation method

A high-entropy alloy and alloy technology, applied in metal processing equipment, manufacturing tools, heat treatment equipment, etc., can solve the problems of high price and high production cost, improve room temperature wear resistance, improve wear resistance, and excellent wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

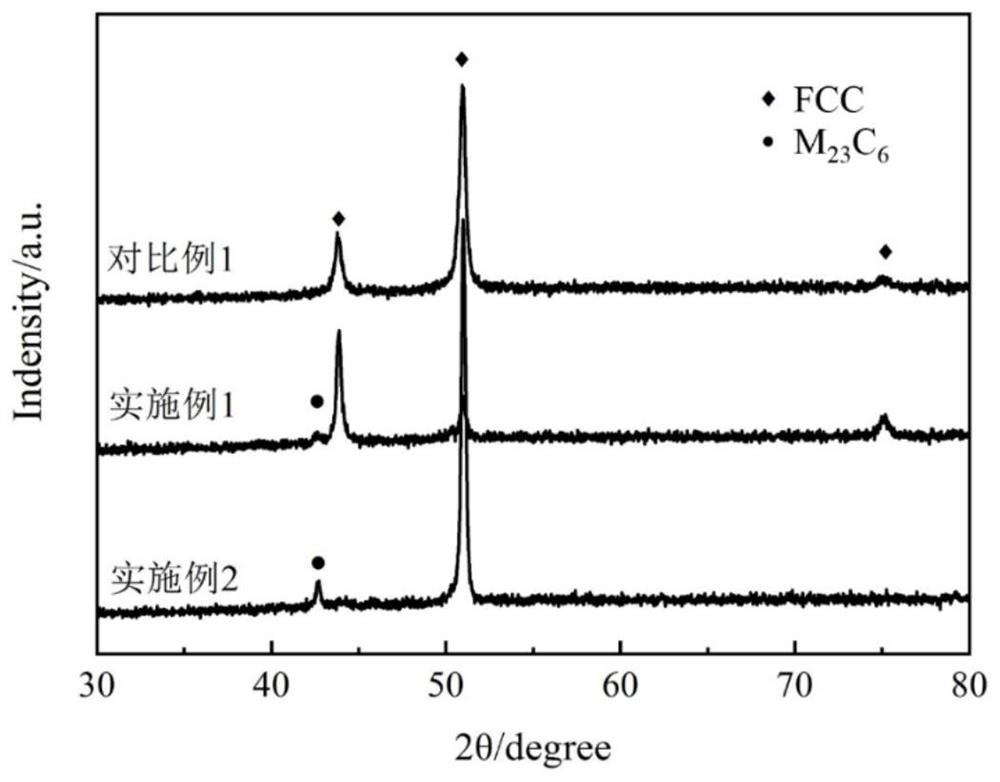

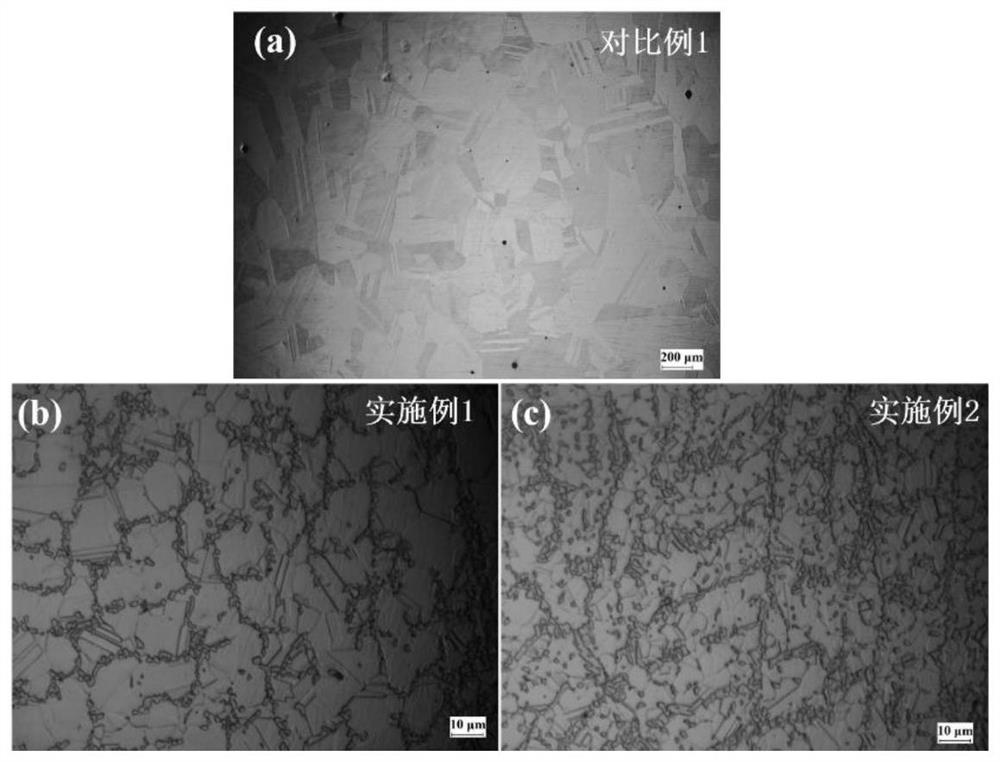

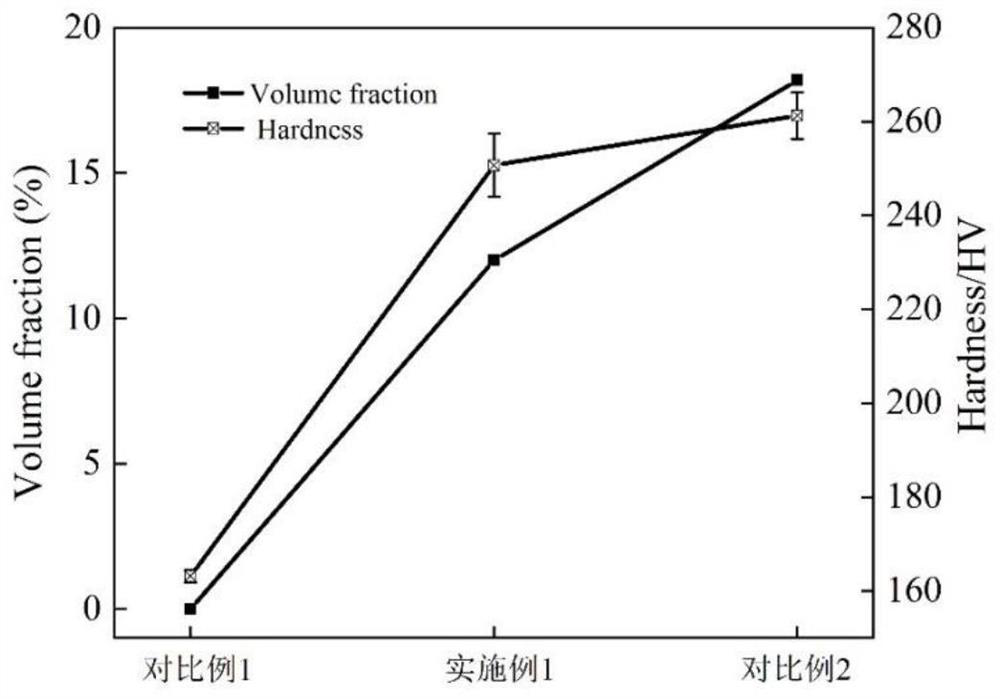

Embodiment 1

[0029] Design according to the high-entropy alloy composition, regardless of the dilution and burning of elements, the mass percentage of each element is: 25.8% Co, 22.8% Cr, 24.5% Fe, 25.7% Ni, 1.2% C, Concrete preparation method comprises the following steps:

[0030] S1. Vacuum arc smelting: Put the weighed elemental Ni, Co, Fe, Cr, and C with a purity higher than 99.9% into the sample tank in turn, and smelt after vacuuming. The smelting process is repeated several times, and the alloy is obtained after cooling. Ingot; wherein, C is C in the form of 1-3 mm particles crushed from carbon rods.

[0031] S2. Hot forging: heat the alloy ingot obtained by melting at 1000°C for 30 minutes, and then hot forge it into a diameter round stick.

[0032] S3. Vacuum heat treatment: After removing the surface scale of the round rod obtained by hot forging, place it in a vacuum heat treatment furnace. After the furnace is evacuated, it is filled with argon for protection, and then quen...

Embodiment 2

[0034] The mass percent of each element in the high-entropy alloy is: 25.8% Co, 22.7% Cr, 24.5% Fe, 25.7% Ni, 1.3% C. The specific preparation method includes the following steps:

[0035] S1. Vacuum arc smelting: Put the weighed elemental Ni, Co, Fe, Cr, and C with a purity higher than 99.9% into the sample tank in turn, and smelt after vacuuming. The smelting process is repeated several times, and the alloy is obtained after cooling. Ingot, wherein, C is C in the form of 1-3 mm particles crushed from carbon rods.

[0036] S2. Hot forging: After the alloy ingot obtained by melting is kept at 1100°C for 10 minutes, it is hot forged into a diameter round stick.

[0037] S3. Vacuum heat treatment: remove the surface scale from the round rod obtained by hot forging, put it in a vacuum heat treatment furnace, vacuumize the furnace and fill it with argon for protection, then heat it at 1000°C for 5 hours and then quench it to eliminate casting and forging defect.

Embodiment 3

[0039] The mass percent of each element in the high-entropy alloy is: 26.8% Co, 21.7% Cr, 23.5% Fe, 26.7% Ni, 1.3% C. The specific preparation method includes the following steps:

[0040] S1. Vacuum arc smelting: Put the weighed elemental Ni, Co, Fe, Cr, and C with a purity higher than 99.9% into the sample tank in turn, and smelt after vacuuming. The smelting process is repeated several times, and the alloy is obtained after cooling. Ingot, wherein, C is C in the form of 1-3 mm particles crushed from carbon rods.

[0041] S2. Hot forging: heat the alloy ingot obtained by smelting at 1050°C for 20 minutes, and then hot forge it into a diameter round stick.

[0042] S3. Vacuum heat treatment: After removing the surface scale of the round rod obtained by hot forging, place it in a vacuum heat treatment furnace. After the furnace is evacuated, it is filled with argon for protection, and then quenched at 1200°C for 3 hours to eliminate casting and forging. defect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com