Robot for wall and floor paving

A technology of walls, floors, and robots, which is applied in the direction of architecture and building construction, can solve the problems of no auxiliary equipment, slow construction progress, poor stability of paving quality, etc., and achieve the effect of convenient storage, reduced volume, and avoiding construction dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

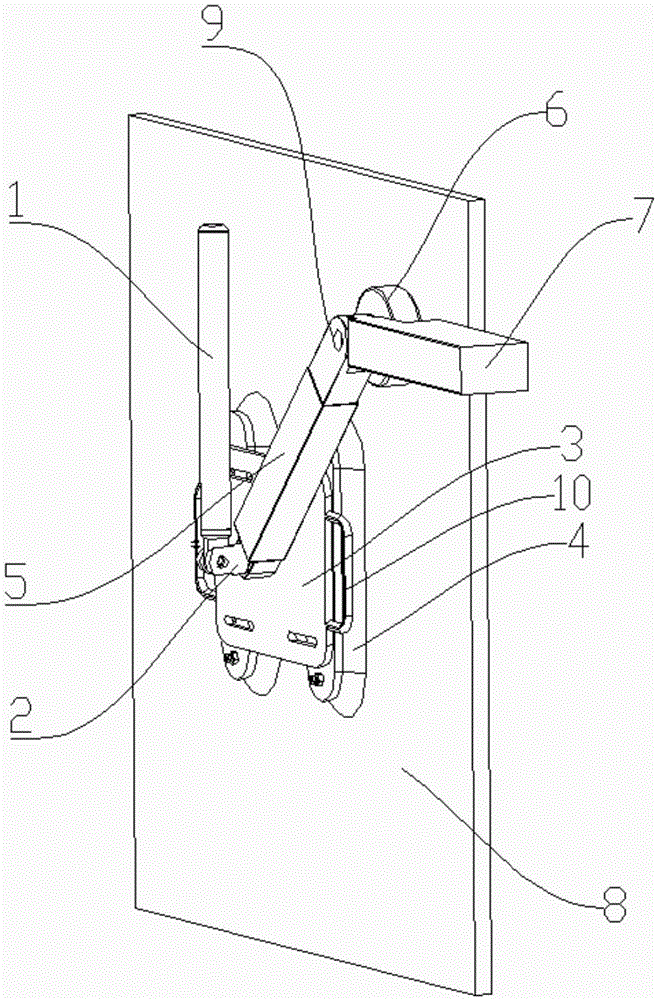

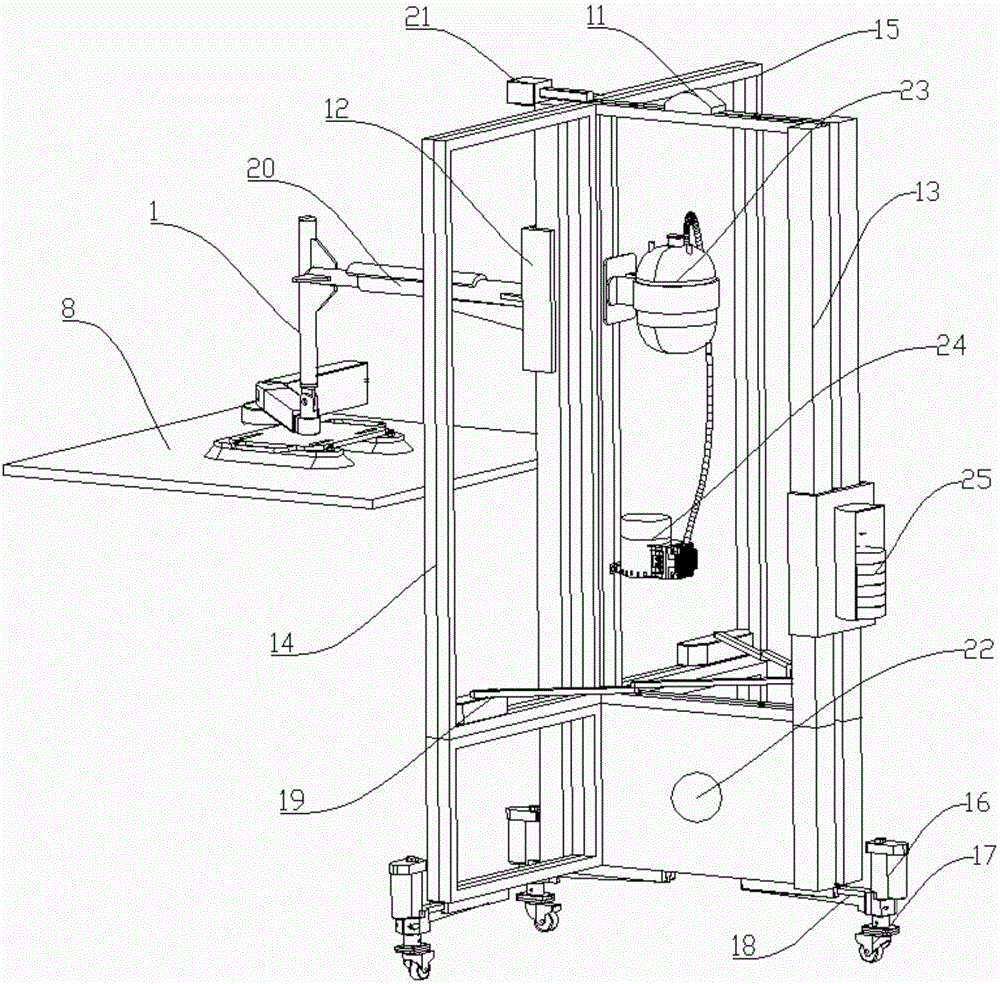

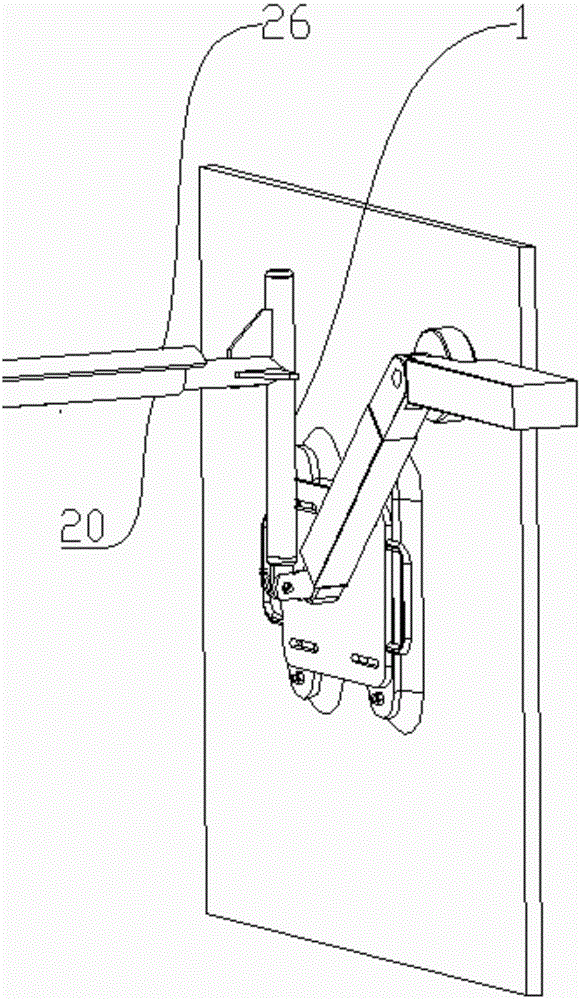

[0049] like figure 1 As shown, it is a specific embodiment of the wall and floor paving working head of the present invention. One end of the support rod 1 is hinged with one end of the rotating head 2, the other end of the rotating head 2 is connected with the suction cup fixing plate 3, the suction cup 4 is installed on the suction cup fixing plate 3, and a locking mechanism is provided at the hinged joint between the support rod 1 and the rotating head 2, preferably , The locking mechanism is an electric locking mechanism, which is controlled and locked by the control system through electric drive. In practical applications, a mechanical locking mechanism can also be used, such as bolt locking or a structure similar to a foldable bicycle locking buckle.

[0050] The suction cup 4 is used to generate negative pressure to absorb the floor tiles or wall tiles to be laid. The suction cup 4 can be connected with external vacuuming equipment, such as vacuum pump, air pump, air c...

Embodiment 2

[0053] On the basis of Embodiment 1, a bearing is provided at the connection between the suction cup fixing plate 3 and the rotating head 2 , and the suction cup fixing plate 3 can rotate axially around the rotating head 2 . After the suction cup absorbs the wall and floor tiles to be laid, the angle can be adjusted by rotating, so that the angle of the wall and floor tiles is consistent with the to-be-paved area.

Embodiment 3

[0055] On the basis of Embodiments 1 and 2, the rotating head 2 is provided with a rotating rod 5 that can rotate axially around the rotating head 2, and a bearing can be provided at the connection between the rotating rod 5 and the rotating head 2 to achieve axial rotation, The rotating rod 5 is telescopic, and the telescopic end 9 of the rotating rod 5 is connected to the vibrator 6 and the leveling device 7 . After the working head absorbs the floor tiles or wall tiles and lays them, the vibrator is close to the wall and floor tiles 8, the vibrator 6 vibrates instead of the rubber hammer hitting the wall and floor tiles 8, and the leveling device 7 is used to measure the wall and floor tiles 8 and the reference wall and floor tiles. 8 is flush. The vibrator 6 and the leveling device 7 are both located on the telescopic end 9 of the rotating rod 5. Since the rotating rod 5 can rotate axially around the rotating head 2, and because the rotating rod 5 is retractable, the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com