Observation point and concurrence based fault injection simulation method and device

A fault injection and observation point technology, applied in electronic circuit testing, integrated circuit testing, etc., can solve problems such as long simulation time and single observation point, and achieve the effect of increasing simulation speed and reducing simulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

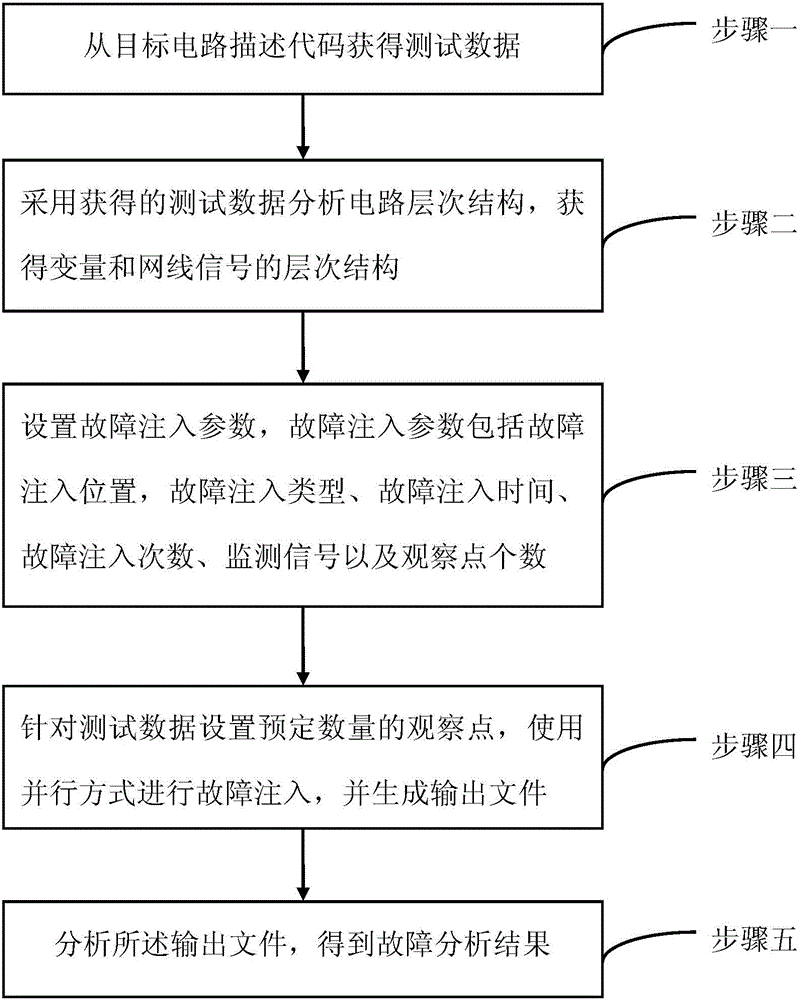

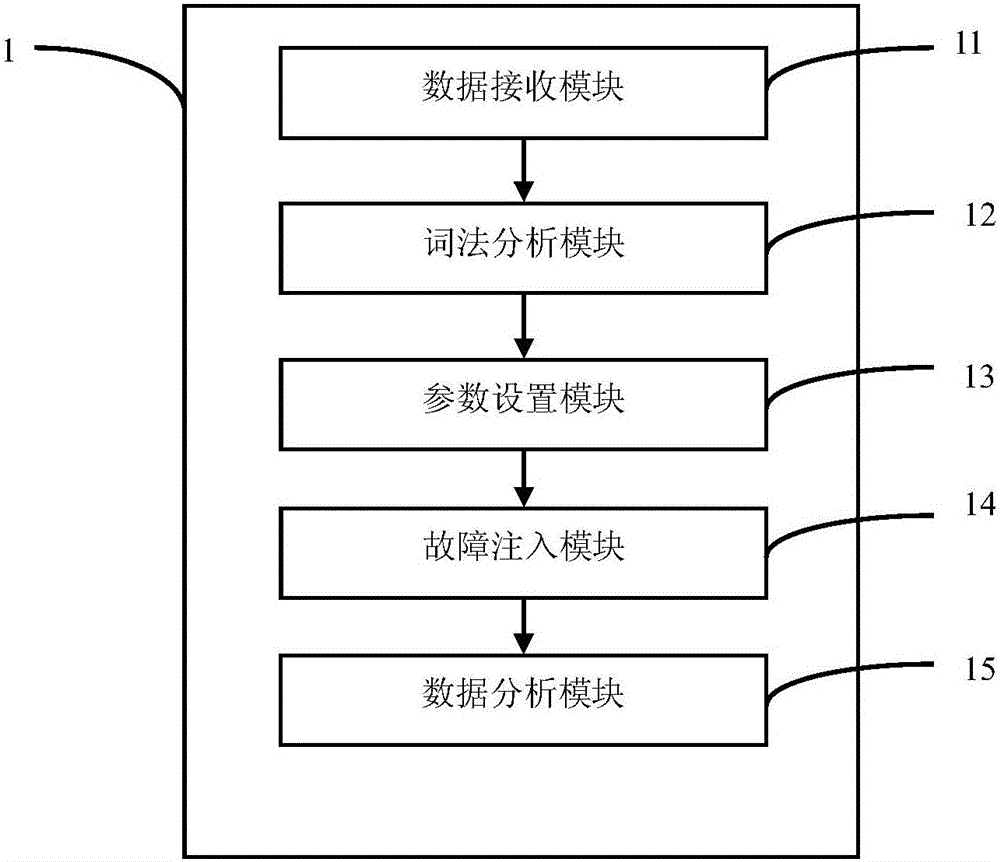

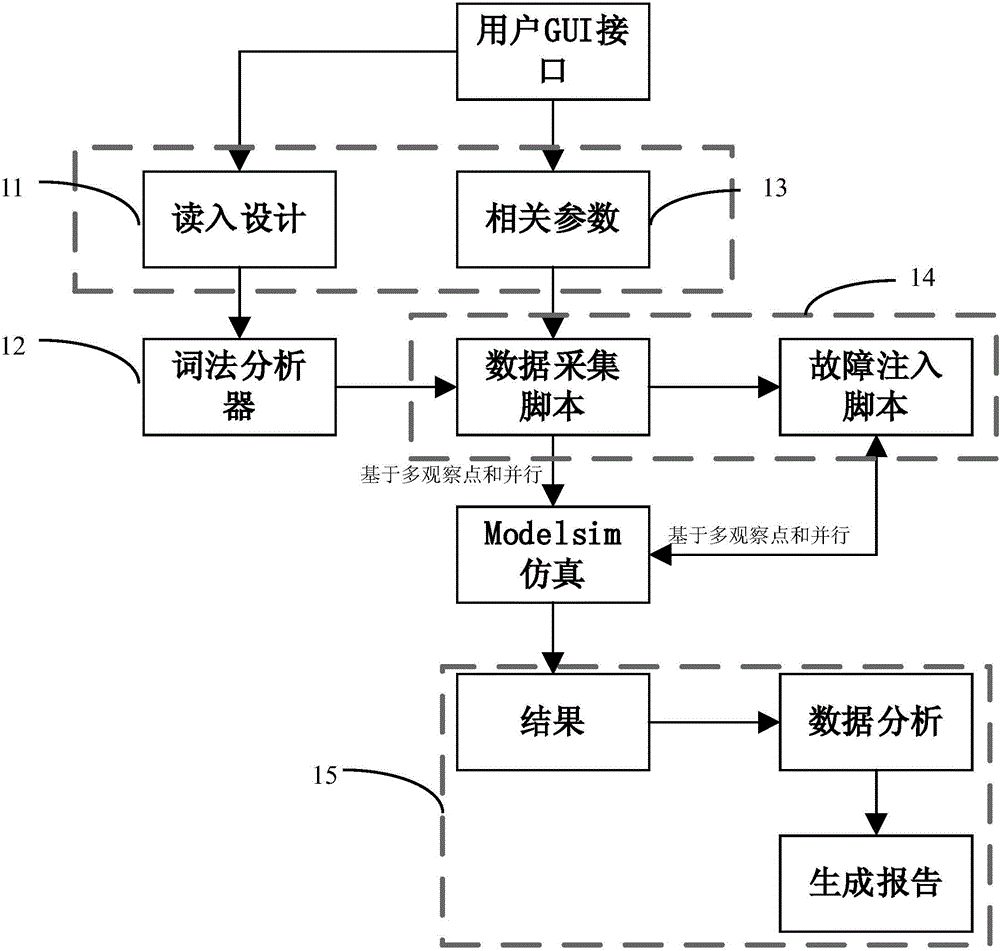

[0023] Specific implementation mode one: as figure 1 As shown, the fault injection simulation method based on observation points and parallelism in this embodiment includes:

[0024] Step 1: Obtain test data from the target circuit description code. The object code can be Verilog source code. In a specific embodiment, the test data may include description source code and test vectors of the target circuit.

[0025] Step 2: Using the obtained test data, analyze the hierarchical structure of the circuit, and obtain the signal paths of variables and network cable signals.

[0026] Step 3: Set fault injection parameters, which include fault injection location, fault injection type, fault injection time, fault injection times, monitoring signal and number of observation points; where the fault injection location can be in the circuit hierarchy Any position; fault injection types can include SEU (single event upset) and SET (single event transient pulse); fault injection time can...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 4, using a parallel method for fault injection includes using at least two VSIM processes at the same time, and the specific VSIM processes can be set according to the performance of the processor. Wherein the VSIM process is the main process in the simulation software Modelsim, and the present invention mainly uses the VSIM process.

[0031] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the method of the present invention is used to evaluate the radiation resistance performance of integrated circuits. In aerospace and other fields, the integrated circuit structure is often very complex, and the simulation speed advantage of the fault injection simulation method of the present invention can be better reflected.

[0033] Other steps and parameters are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com