Method for opening concentric elliptical holes in multi-layer superimposed arc webs with different curvatures

A concentric ellipse and different curvature technology, applied in the field of workpiece scribing and opening, can solve the problems of large deviation, high production cost, low opening precision, etc., and achieve the effect of high concentricity, high work efficiency and saving production resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

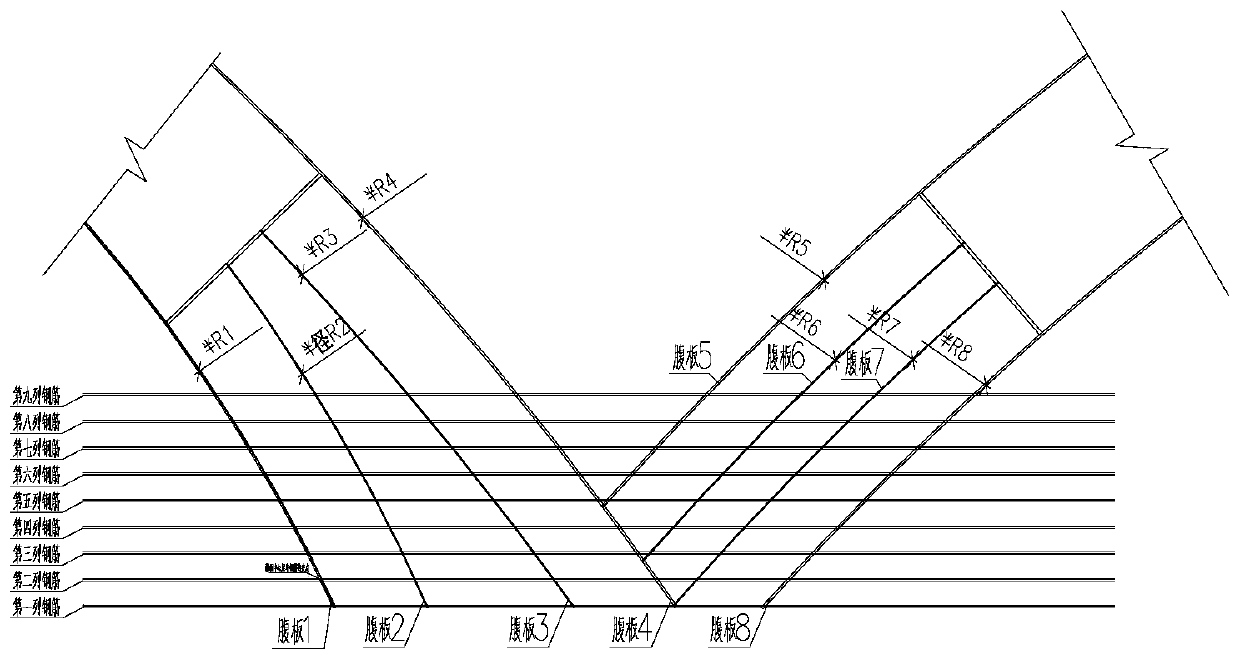

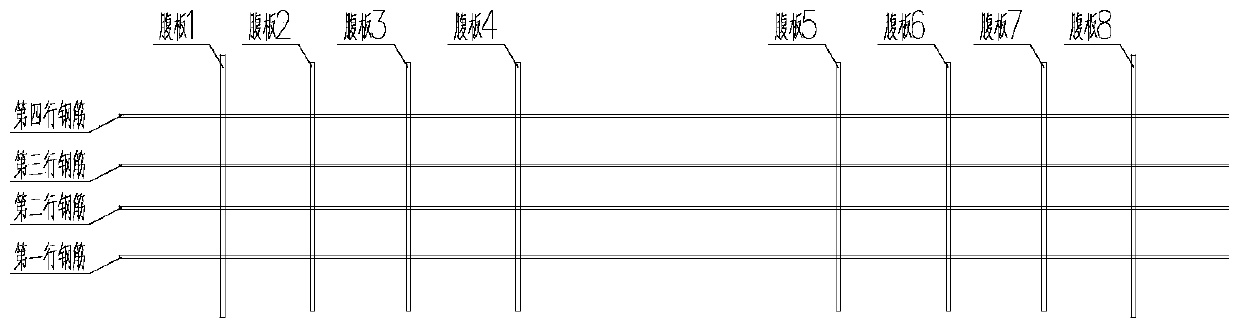

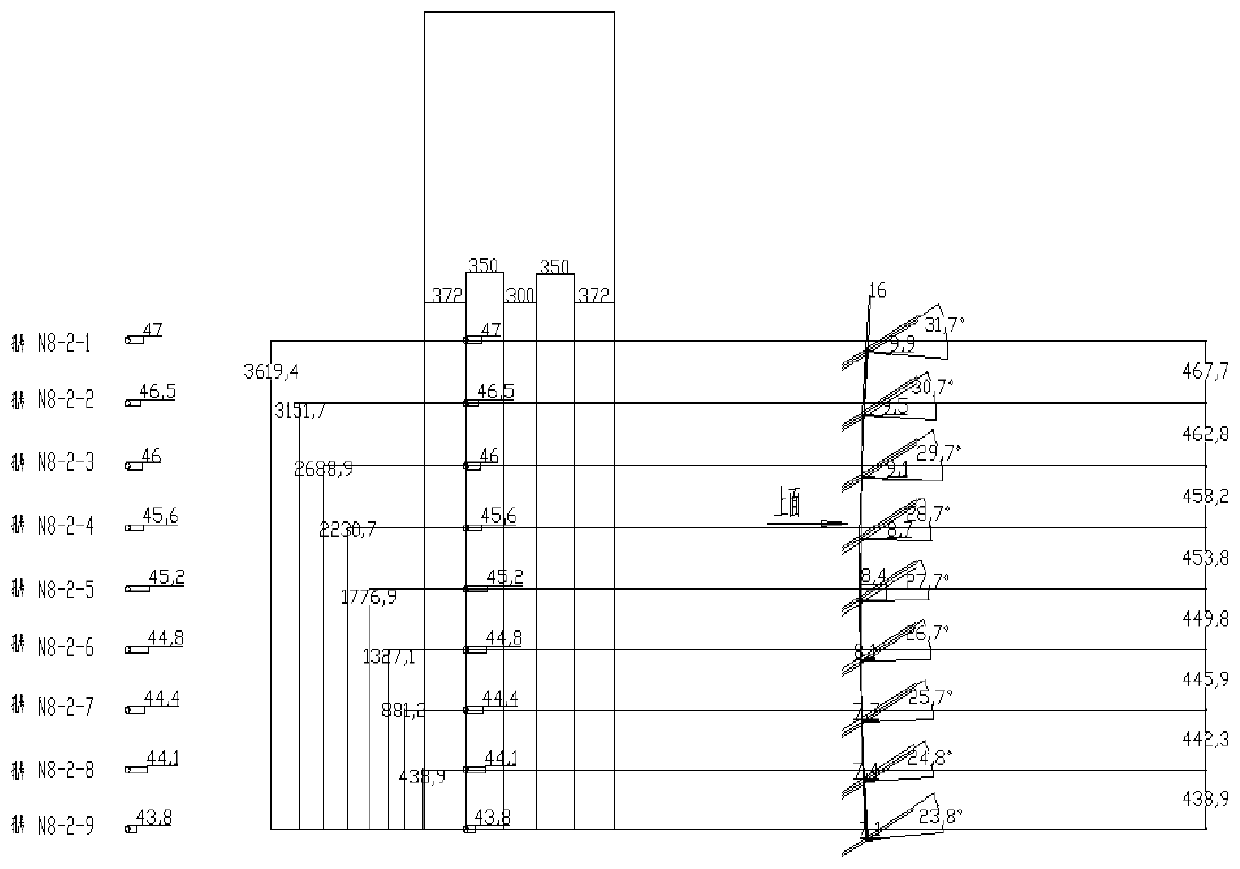

[0025] See the accompanying drawings for details. This embodiment provides a method for opening concentric elliptical holes with multi-layer superimposed circular arc webs with different curvatures. Use drawing software to determine the ellipse center point and outer contour of the neutral layer of the steel plate through lofting calculations; after drawing The center point and outer contour of the ellipse are converted to the outer skin of the steel plate and drawn manually to form a graphic; through programming software, CNC cutting machine is used to cut, and four rows and nine columns of concentric circles with gradient intersecting angles are realized on eight layers of superimposed arc webs with different curvatures. Oval hole, the specific method steps are as follows:

[0026] 1) Determine each intersection point between the neutral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com