Crawler self-propelled round bale bundling machine

A self-propelled, baler technology, used in packaging, chassis of agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of inability to complete the operation normally, unadjustable ground pressure, poor operation flexibility, etc., to improve the operation effect. , Increase the separation ability, the effect of short working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

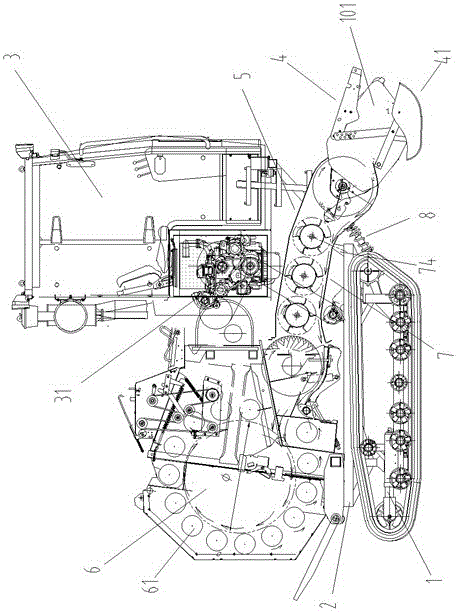

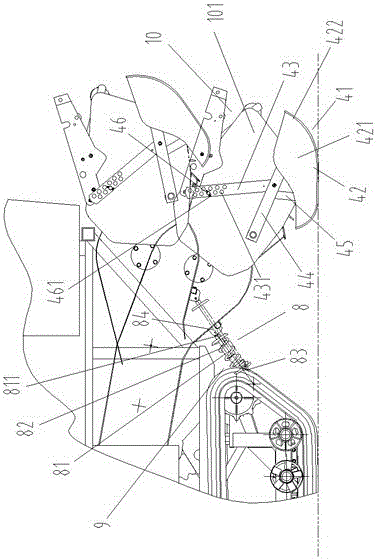

[0022] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of the 9YGZ-1000 crawler self-propelled round bale picking and tying machine.

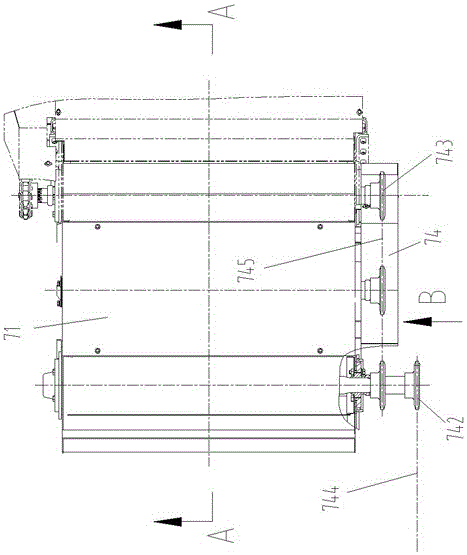

[0023] Such as figure 1 As shown, this embodiment includes a crawler chassis 1, a frame 2, a cab assembly 3, a profiling picker 4, a forage conveyor 5, and a baling chamber 6. The frame 2 is fixed on the upper side of the crawler chassis 1. , The cab assembly 3 is fixed on the front end of the frame 2, the engine 31 is located on the lower left side of the cab assembly 3, the bundling chamber 6 is fixed on the rear end of the frame 2, and the profiling picker 4 is located on the crawler chassis 1 On the right side, its rear end is connected to the front end of the forage conveyor 7, and the rear end of the forage conveyor 7 leads to the baling chamber 6. The baling chamber 6 is provided with a circle of 14 grass pressing rollers 61 around the center of the baling chamber 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com