Method for preparing and reproducing tobacco leaves with microorganisms

A technology of reconstituted tobacco leaves and microorganisms, which is applied in the field of preparing reconstituted tobacco leaves and using microorganisms to prepare reconstituted tobacco leaves, achieving the effects of simple operation, good social and economic benefits, and improved taste quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

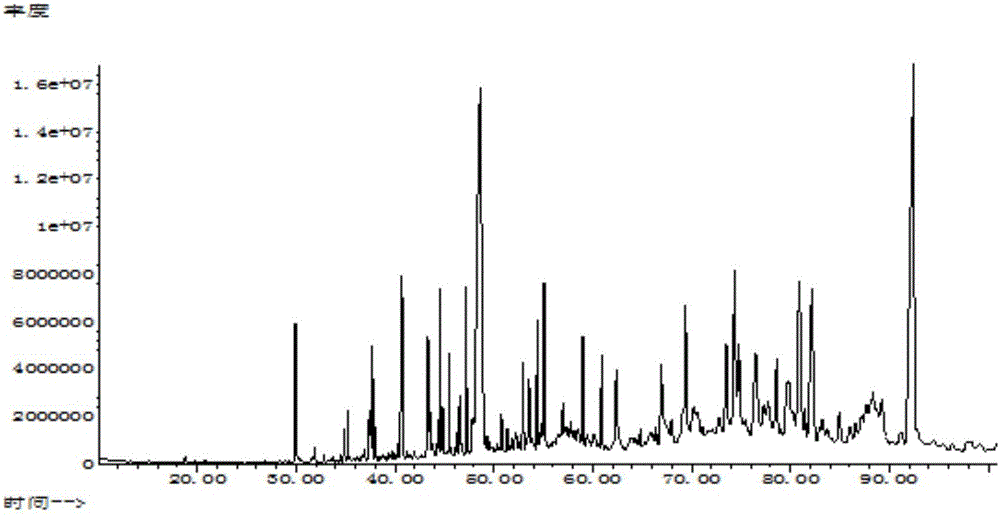

Embodiment 1

[0029] A method for preparing reconstituted tobacco leaves using microorganisms, comprising the following steps:

[0030] (1) Put tobacco raw material and water into the fermenter according to the ratio of 1:6 in mass ratio, after leaching for 20min, add Bacillus cereus bacterial liquid according to 6% inoculum amount (tobacco raw material+water), bacterial liquid The OD value of 1.0, leaching, Maillard reaction occurs simultaneously during leaching, separates after leaching, obtains extract and insoluble matter;

[0031] The extraction conditions are: temperature 50°C, time 2h, stirring speed 150rpm, dissolved oxygen 20%;

[0032] The tobacco raw material is a mixture of tobacco stems, tobacco dust and low-grade tobacco leaves at a mass ratio of 5:3:2;

[0033] (2) Carry out vacuum rotary evaporation concentration to extract solution to obtain concentrated solution, the Baume degree of concentrated solution is 25 ° Bé; Carry out papermaking technology to copy insoluble matte...

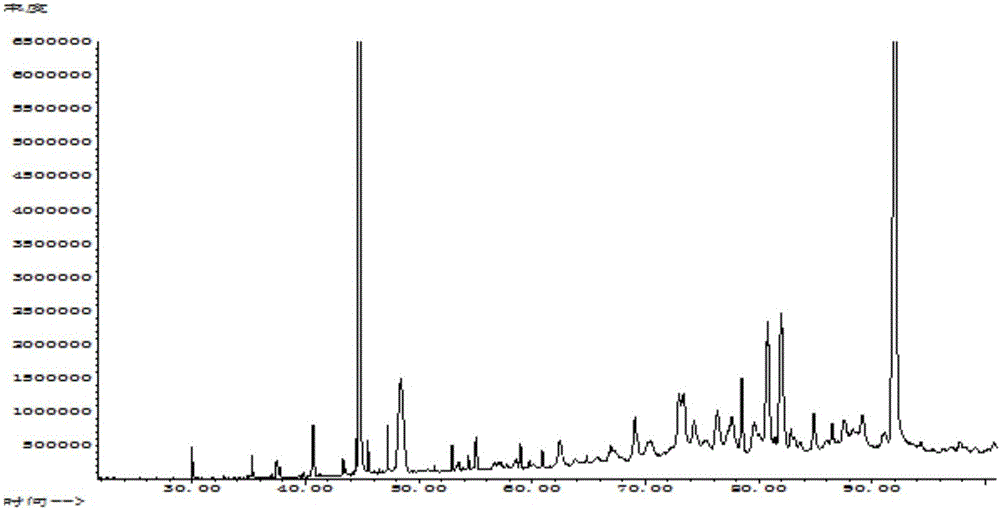

Embodiment 2

[0036] A method for preparing reconstituted tobacco leaves using microorganisms, comprising the following steps:

[0037] (1) Tobacco raw material and water are added in the fermenter according to the ratio of 1:6 according to the mass ratio, after leaching for 20min, then add Bacillus cereus bacterium liquid according to the inoculation amount of 10%, the OD value of bacterium liquid is 1.0, Leaching, Maillard reaction occurs at the same time as leaching, and separation is carried out after leaching to obtain extract and insoluble matter;

[0038] The extraction conditions are: temperature 40°C, time 2h, stirring speed 150rpm, dissolved oxygen 20%;

[0039] The tobacco raw material is a mixture of tobacco stems, tobacco dust and low-grade tobacco leaves at a mass ratio of 5:3:2;

[0040] (2) Carry out vacuum rotary evaporation concentration to extract solution to obtain concentrated solution, the Baume degree of concentrated solution is 25 ° Bé; Carry out papermaking technol...

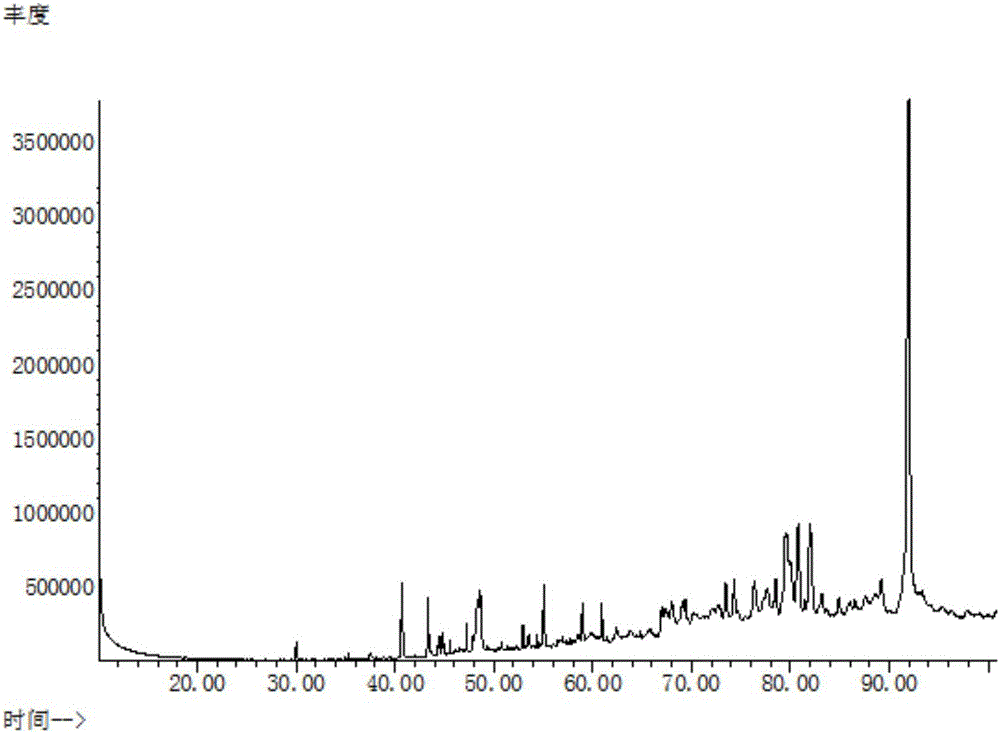

Embodiment 3

[0043] A method for preparing reconstituted tobacco leaves using microorganisms, comprising the following steps:

[0044] (1) Tobacco raw material and water are added in the fermenter according to the ratio of 1:6 according to the mass ratio, after leaching for 20min, then add Bacillus cereus bacterium liquid according to the inoculation amount of 8%, the OD value of bacterium liquid is 1.0, Leaching, Maillard reaction occurs at the same time as leaching, and separation is carried out after leaching to obtain extract and insoluble matter;

[0045] The extraction conditions are: temperature 35°C, time 3h, stirring speed 150rpm, dissolved oxygen 20%;

[0046] The tobacco raw material is a mixture of tobacco stems, tobacco dust and low-grade tobacco leaves at a mass ratio of 5:3:2;

[0047] (2) Carry out vacuum rotary evaporation concentration to extract solution to obtain concentrated solution, the Baume degree of concentrated solution is 25 ° Bé; Carry out papermaking technolo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Baume degrees | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com