Method for preparing pandermite-ethyl oxalate composite modified kaolin

A technology of ethyl oxalate and compound modification, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low grade quality and purity, unfavorable direct utilization, etc., and achieve Improve the adsorption effect, good adsorption performance and regeneration, and the effect of large application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

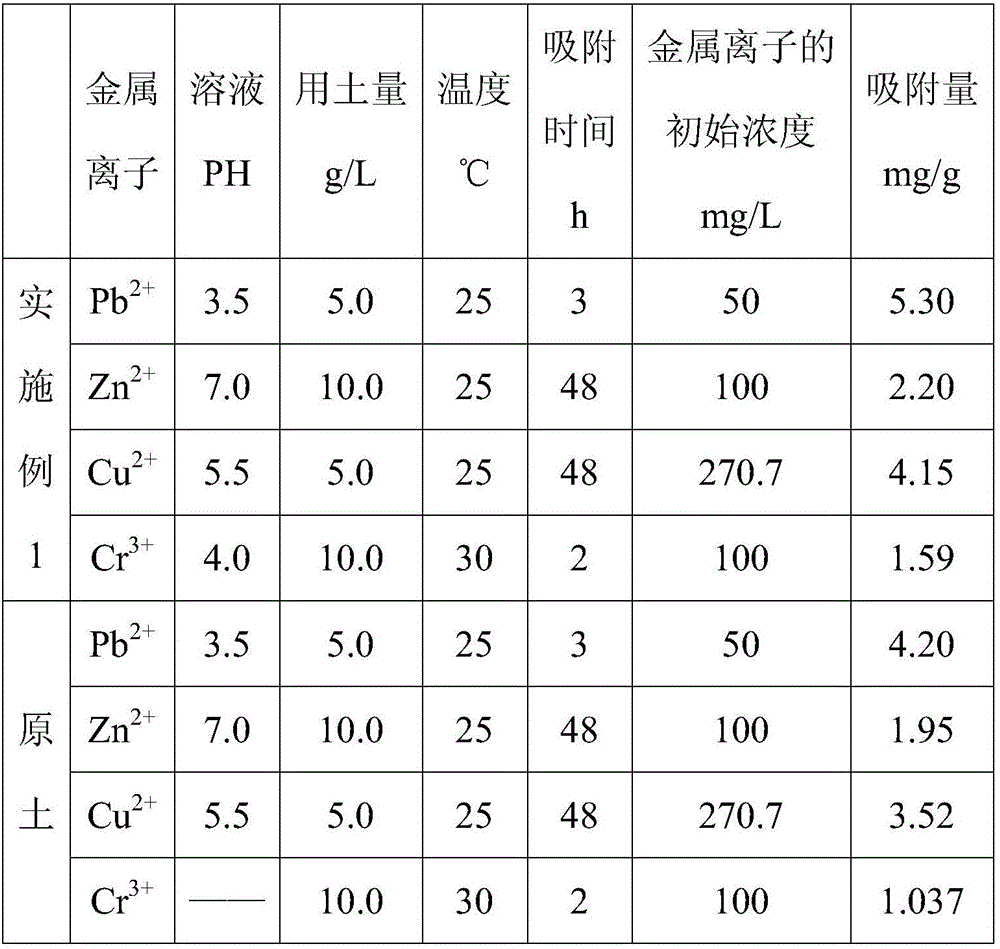

Embodiment 1

[0014] A preparation method of white boronite ethyl oxalate composite modified kaolin, comprising the steps of:

[0015] (1) Ingredients: take by weighing 160g of leucumite, 500g of ethyl oxalate, and 900g of kaolin respectively;

[0016] (2) Mixing: mix kaolin and vitreousite evenly, then add ethyl oxalate and stir evenly;

[0017] (3) Reaction: Pour the mixture into a high-temperature and high-pressure reactor, fill the reactor with inert gas and exhaust the air, adjust the pressure in the reactor to 2.2Mpa, and the temperature to 280°C, and place the reactor in an ultrasonic field. The frequency of the ultrasonic field is 32KHz, and the power density is 0.48w / cm 2 ;

[0018] (4) Drying: keep stirring in the reactor during the reaction process, after reacting for 20mim, cool naturally to 80°C, pour the material out of the reactor and spread it into an oven at 80°C, so that the unreacted ethyl oxalate volatilizes Clean, and then grind until the particle size is less than 1...

Embodiment 2

[0024] A preparation method of white boronite ethyl oxalate composite modified kaolin, comprising the steps of:

[0025] (1) Batching: the ratio by weight is boronite: ethyl oxalate: kaolin=5:20:40 and take each component for subsequent use;

[0026] (2) Mixing: mix kaolin and vitreousite evenly, then add ethyl oxalate and stir evenly;

[0027] (3) Reaction: Pour the mixed material into a high-temperature and high-pressure reactor, fill the reactor with inert gas to exhaust the air, adjust the pressure in the reactor to 2Mpa, and the temperature to 260°C, and place the reactor in an ultrasonic field. The frequency of the field is 30KHz and the power density is 0.45w / cm 2 ;

[0028] (4) Drying: After reacting for 15mim, cool naturally to 75°C, pour the material out of the reaction kettle and spread it into an oven at 75°C, so that the unreacted ethyl oxalate is volatilized, and the product is obtained.

Embodiment 3

[0030] A preparation method of white boronite ethyl oxalate composite modified kaolin, comprising the steps of:

[0031] (1) Batching: the ratio by weight is leucumite: ethyl oxalate: kaolin=10:30:50 and take each component for subsequent use;

[0032] (2) Mixing: mix kaolin and vitreousite evenly, then add ethyl oxalate and stir evenly;

[0033] (3) Reaction: Pour the mixed material into a high-temperature and high-pressure reactor, fill the reactor with inert gas and exhaust the air, adjust the pressure in the reactor to 2.5Mpa, and the temperature to 200°C, and place the reactor in an ultrasonic field. The frequency of the ultrasonic field is 35KHz, and the power density is 0.5w / cm 2 ;

[0034] (4) Drying: After reacting for 30mim, cool naturally to 85°C, pour the material out of the reaction kettle and spread it into an oven at 85°C, so that the unreacted ethyl oxalate is volatilized, and the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com