Ammonium perchlorate embedded carbon/metallic oxide composite catalyst, and preparation method thereof

A technology of composite catalyst and ammonium perchlorate, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as particle agglomeration, reduce high-temperature thermal decomposition temperature, and increase apparent emission. heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

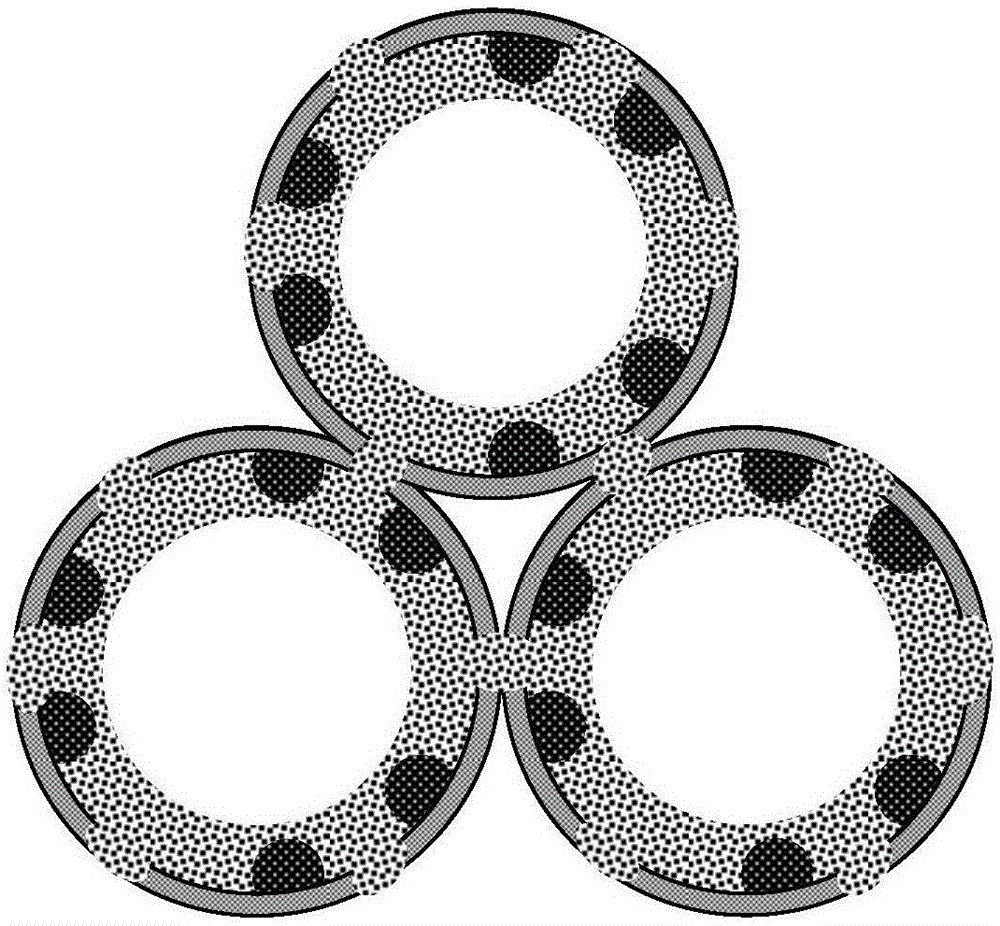

[0046] Three-dimensional ordered macroporous-mesoporous carbon / Fe embedded in ammonium perchlorate 2 o 3 Composite catalyst, the metal precursor is Fe(NO 3 ) 3 9H 2 O, the content of ammonium perchlorate is 30wt%.

[0047] Get the Pluronic F127 of 1.0g to be dissolved in 14.0g dehydrated alcohol at room temperature, stir and mix with the ethanol solution (mass fraction of 20%) of the resole phenolic resin of 10.0g; (NO 3 ) 3 9H 2 O ethanol solution was dropped into the above solution, and after stirring evenly, a dark blue-black mixed solution was obtained.

[0048] The mixed solution was added dropwise on SiO with a microsphere size of 335nm 2 Immerse the colloidal crystals in the mixed solution, let stand at room temperature until the organic solvent is completely volatilized, and obtain the complex.

[0049] After the composite was thermally cured in an oven at 70 °C for 4 hours, it was heated in a tube furnace for N 2 Calcined at 600°C for 3 hours in the atmosphe...

Embodiment 2

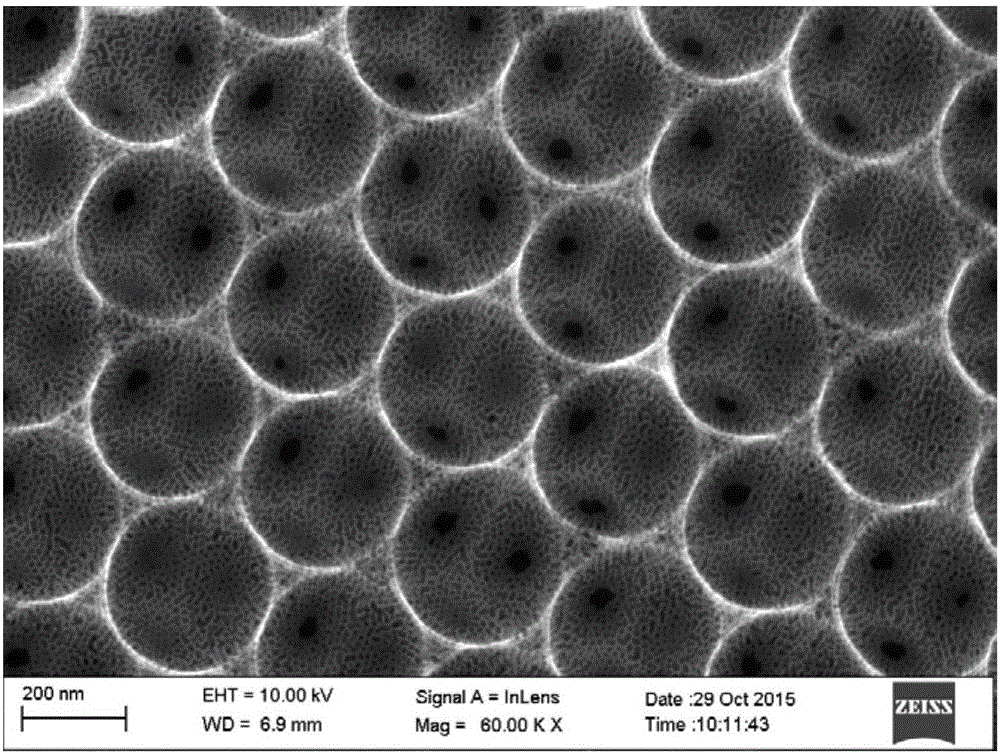

[0053] Three-dimensional ordered macroporous-mesoporous carbon / Fe embedded in ammonium perchlorate 2 o 3 Composite catalyst, the metal precursor is Fe(NO 3 ) 3 9H 2 O, ammonium perchlorate content is 60wt%, its SEM photo is as Figure 5 shown.

[0054] Dissolve 1.0 g of Pluronic F127 in 14.0 g of absolute ethanol at room temperature, add 10.0 g of resole phenolic resin ethanol solution, and stir until uniform. Fe(NO 3 ) 3 9H 2 O ethanol solution was dropped into the above solution, and after stirring evenly, a dark blue-black mixed solution was obtained.

[0055] The mixed solution was added dropwise on SiO with a microsphere size of 335nm 2 The colloidal crystals are immersed in the solution, and left standing at room temperature until the organic solvent is completely volatilized to obtain the complex.

[0056] After the composite was thermally cured in an oven at 70 °C for 4 hours, it was heated in a tube furnace for N 2 Calcined at 600°C for 3 hours in the atmos...

Embodiment 3

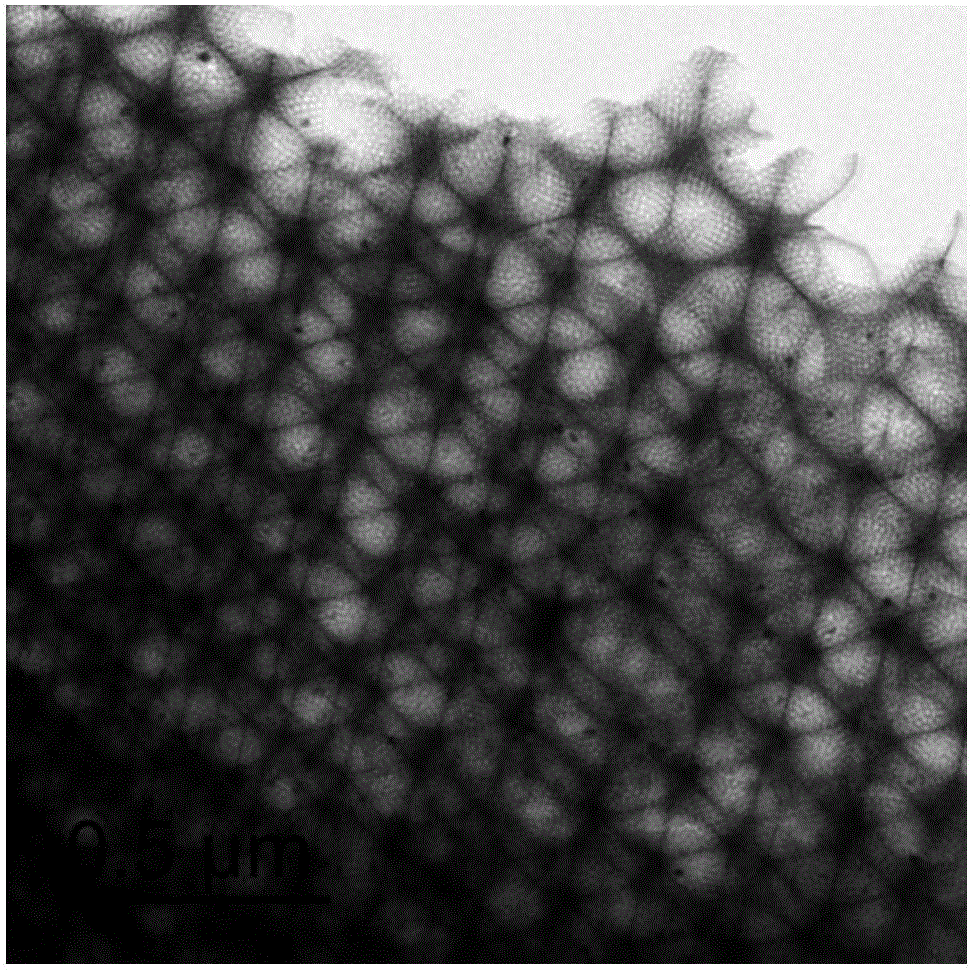

[0060] Three-dimensional ordered macroporous-mesoporous carbon / Fe embedded in ammonium perchlorate 2 o 3 Composite catalyst, the metal precursor is Fe(NO 3 ) 3 9H 2 O, the content of ammonium perchlorate is 80wt%.

[0061] Get 1.0g of Pluronic F127 at room temperature and dissolve in 14.0g absolute ethanol, stir and mix with the ethanol solution of 10.0g resole phenolic resin; then molar concentration is 1.0mol / L Fe(NO 3 ) 3 9H 2 O ethanol solution was dropped into the above solution, and after stirring evenly, a dark blue-black mixed solution was obtained.

[0062] The mixed solution was added dropwise on SiO with a microsphere size of 335nm 2 Immerse the colloidal crystals in the mixed solution, let stand at room temperature until the organic solvent is completely volatilized, and obtain the complex.

[0063] After the composite was thermally cured in an oven at 70 °C for 4 hours, it was heated in a tube furnace for N 2Calcined at 600°C for 3 hours in the atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com