Pyrolysis gas conveying and spraying structure

A technology of pyrolysis gas and gas injection holes, which is applied in the direction of catalyst regeneration/reactivation, separation of dispersed particles, physical/chemical process catalysts, etc. It can solve problems such as large influence of system pressure, valve damage, and flow instability, etc., to achieve The effect of system pressure is small, the damage is reduced, and the spray is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

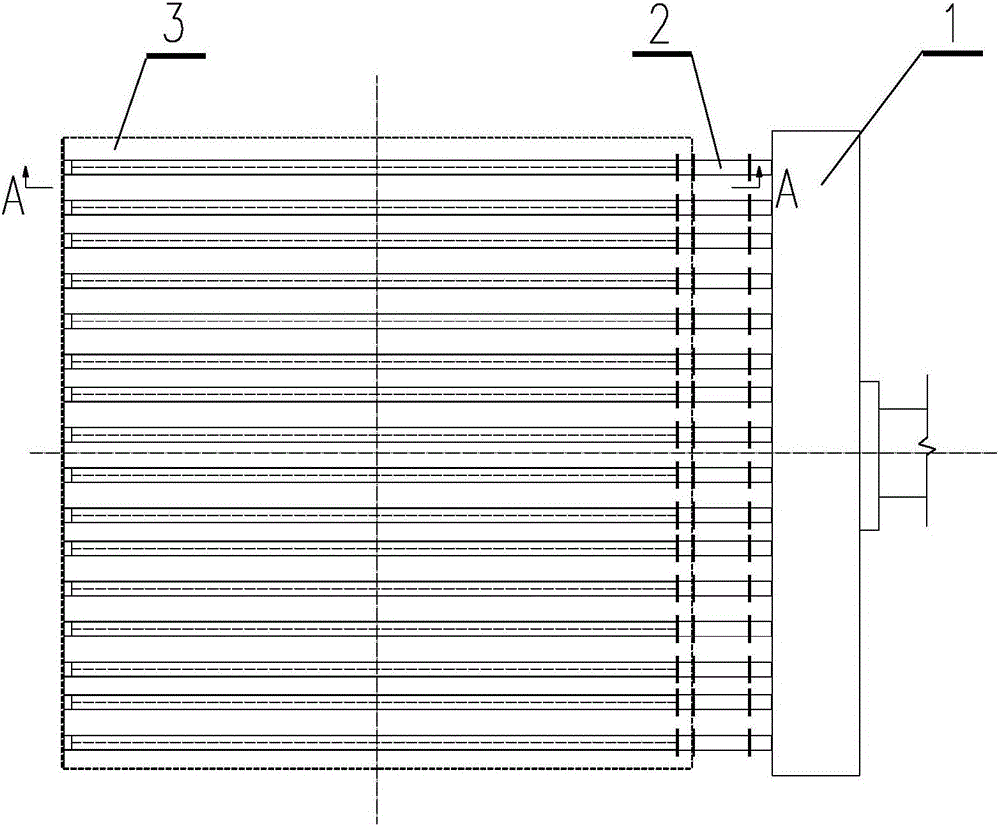

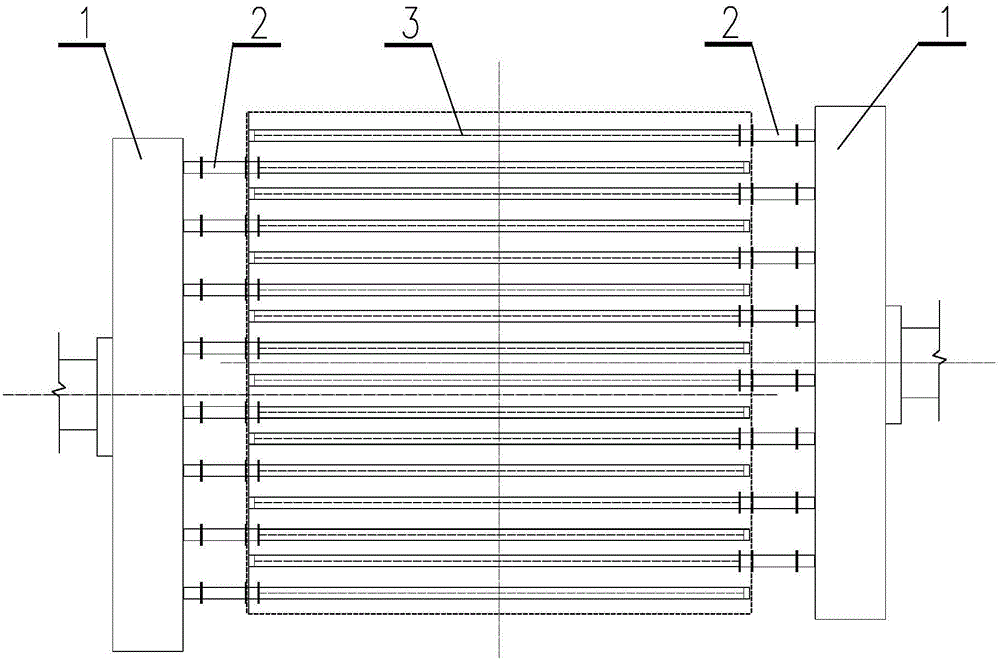

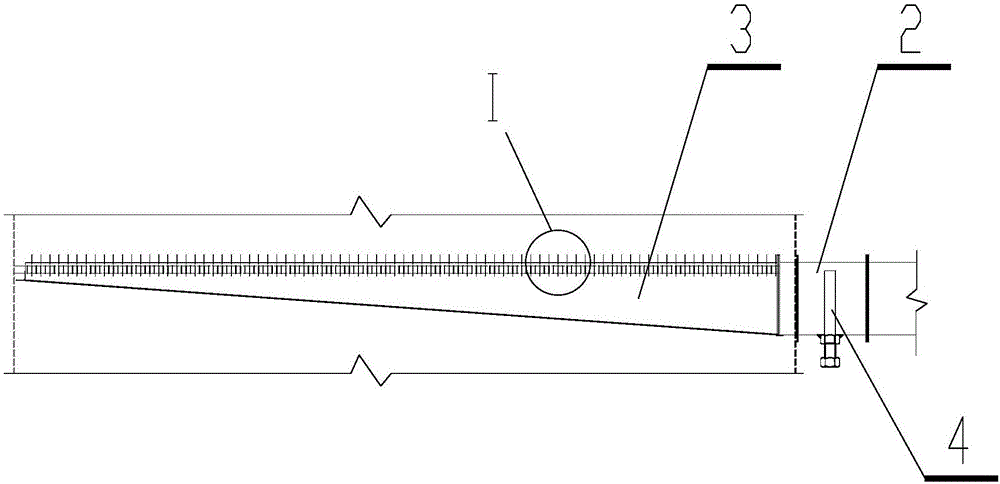

[0023] Such as figure 1 As shown, a pyrolysis gas delivery injection structure according to the present invention includes a pyrolysis gas buffer chamber 1, a flow regulating short pipe 2 and a pyrolysis gas branch pipe 3; the pyrolysis gas buffer chamber 1 is used to transfer an external heat source Buffer before introducing the pyrolysis gas branch pipe 3; the flow regulating short pipe 2 is used to connect the pyrolysis gas buffer chamber 1 and the pyrolysis gas branch pipe 3, and control the pressure and flow rate of the pyrolysis gas; the pyrolysis gas branch pipe 3 is a square cross-section gradient and one end of its large cross-section is connected to the flow regulating short pipe 2; the pyrolysis gas branch pipe 3 is provided with a gas injection hole 5, and a plurality of pyrolysis gas branch pipes 3 are evenly arranged side by side, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com