A kind of external rotation feeding device used for large-scale thin-walled cylindrical piece counter-wheel spinning equipment

A technology of spinning equipment and thin-walled tubes, which is applied in the field of feeding devices, can solve problems such as poor versatility, high mold cost, and long manufacturing cycle, and achieve the effects of reduced production costs, good versatility, and reduced manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

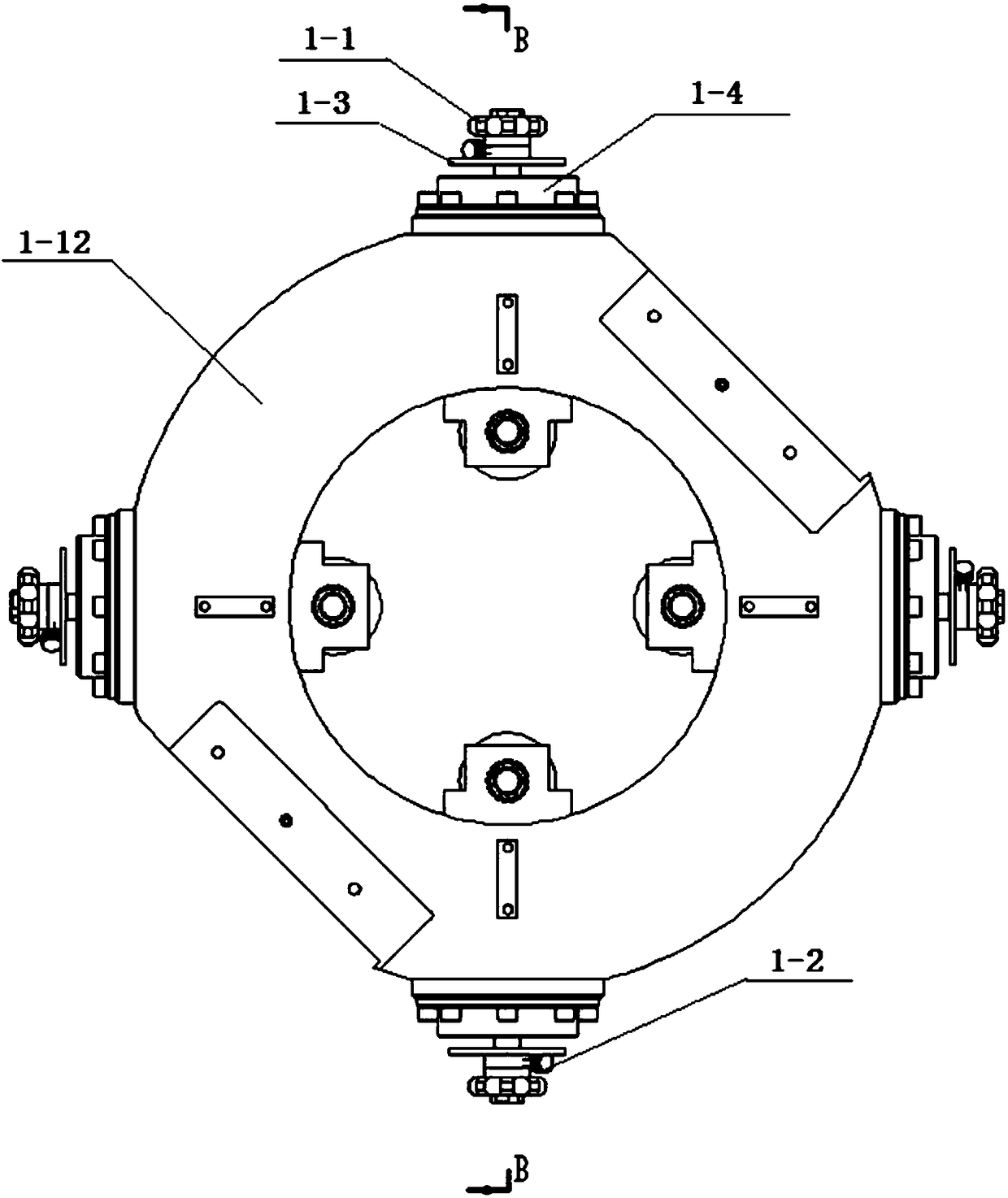

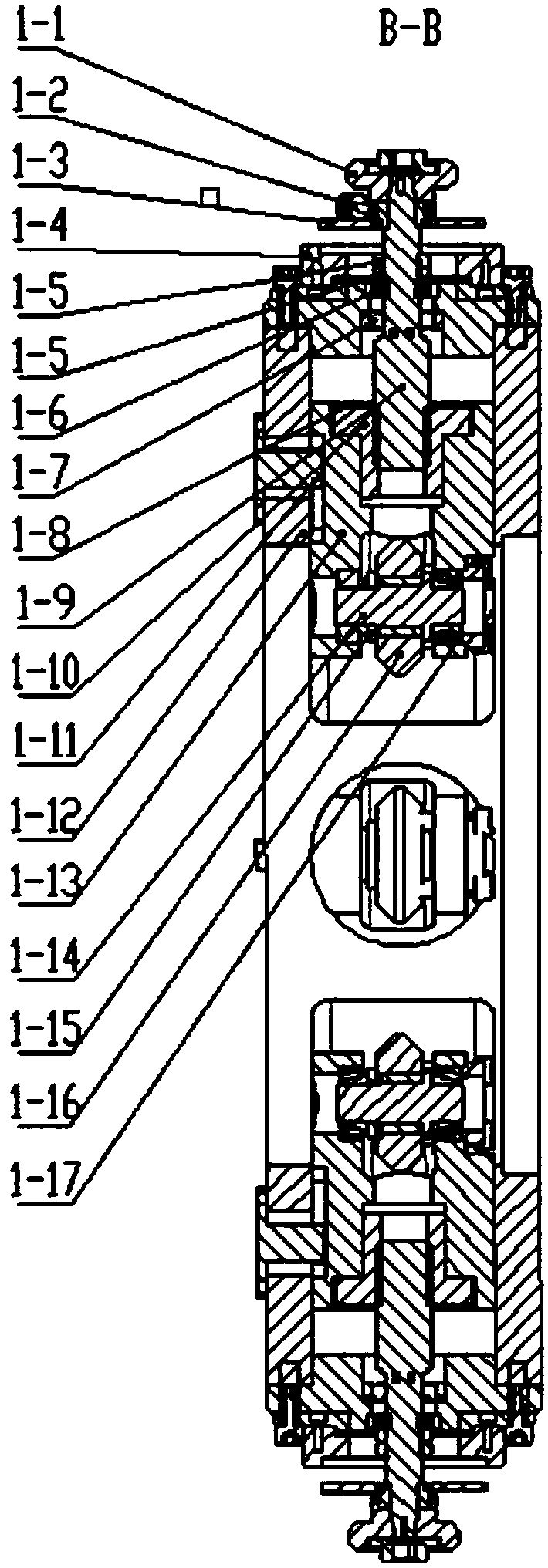

[0011] Specific embodiment one: combine 1 to Figure 5 Describe this embodiment, a kind of external rotation feeding device used for large-scale thin-walled cylindrical part counter-wheel spinning equipment in this embodiment includes a wheel base guide plate 1-12, a plurality of external rotation components and a plurality of external rotation Feed fixed seat assembly, a plurality of external rotation feed fixed seat assemblies are installed on the wheel seat guide disc 1-12, and the lower part of each external rotation feed fixed seat assembly is connected with an external rotation assembly;

[0012] Each external rotation assembly includes a rotary wheel 1-16, a rotary wheel shaft 1-14, a rotary wheel bearing spacer 1-15, a pair of tapered roller bearings 1-17, a lifting nut 1-10 and a rotary wheel seat 1-1. 13. The wheel seat 1-13 is installed on the wheel seat guide plate 1-12, the lifting nut 1-10 is seated on the wheel seat 1-13, and the wheel shaft 1-14 passes through ...

specific Embodiment approach 2

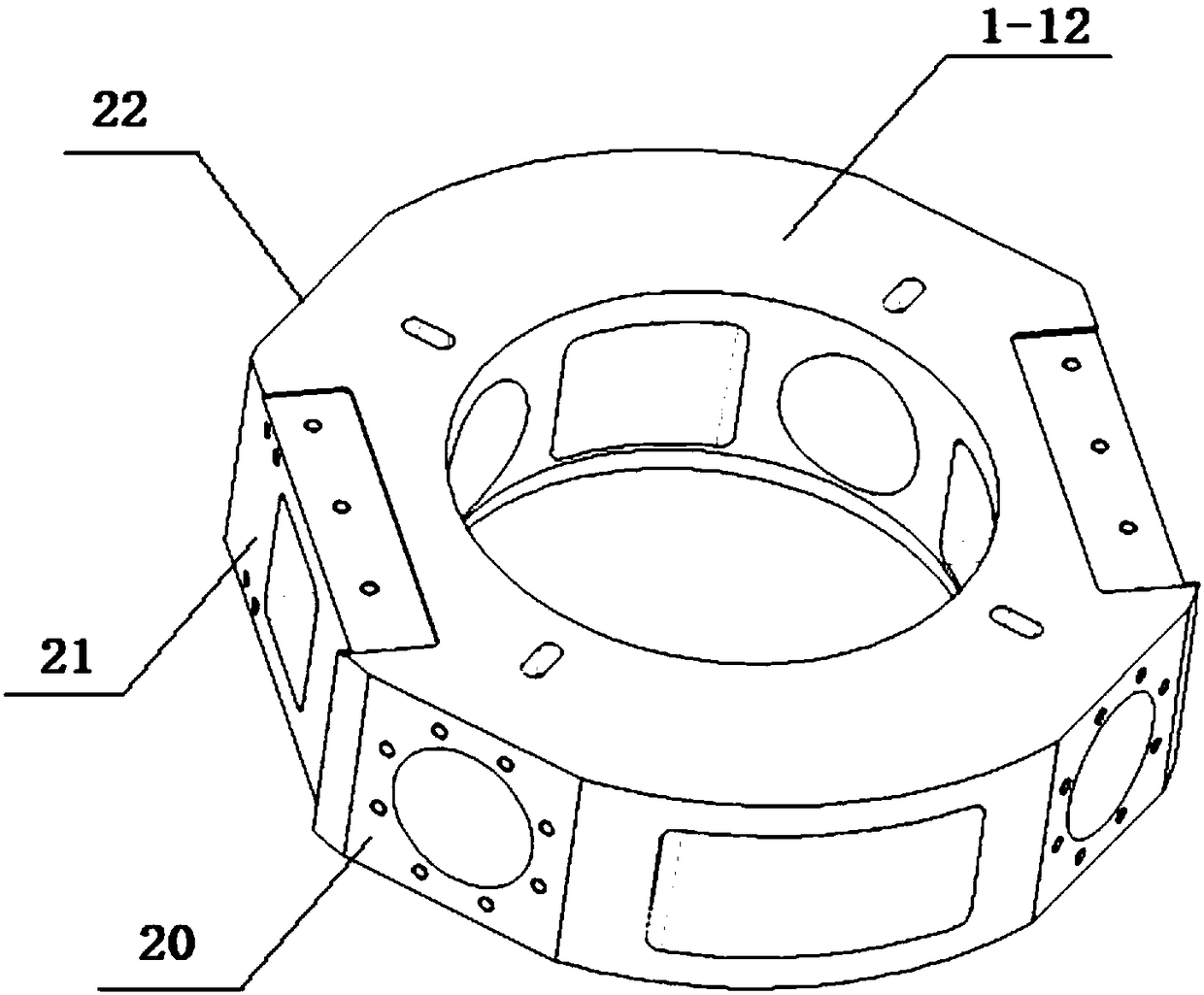

[0015] Specific implementation mode two: combination image 3 To illustrate this embodiment, the outer end face of the wheel seat guide plate 1-12 of this embodiment is a circular guide plate formed by two sections of arc end surfaces and two sections of planes arranged alternately. Concatenated sequentially. Such arrangement facilitates providing symmetrical spinning angles and directions. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination image 3 Describe this embodiment, the three planes in this embodiment include a first rectangular plane 20, a second rectangular plane 21 and a third rectangular plane 22, the first rectangular plane 20, the second rectangular plane 21 and the third rectangular plane 22 Connected in sequence, the lengths of the first rectangular plane 20 and the third rectangular plane 22 are smaller than the length of the second rectangular plane 21 . With such arrangement, it is convenient to arrange the outer rotation components evenly. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com