An integrated control method for welding machine and manipulator of plasma welding equipment

A technology of plasma welding and control method, applied in plasma welding equipment, welding equipment, welding equipment and other directions, can solve the problems of affecting the accuracy of the operation sequence, affecting the operation efficiency, and the complexity of the panel, so as to eliminate the action of repeatedly adjusting the welding current, Wide welding range and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

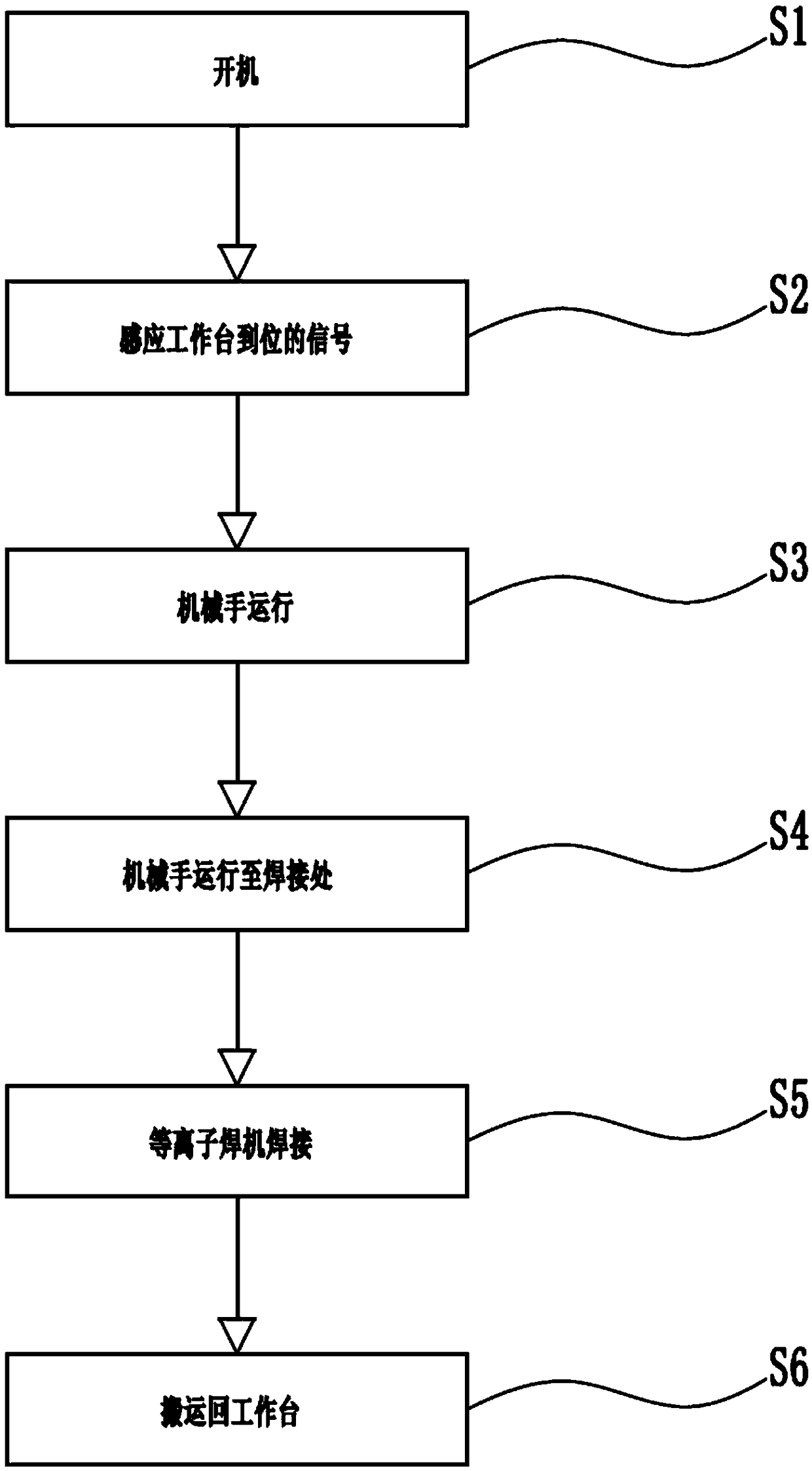

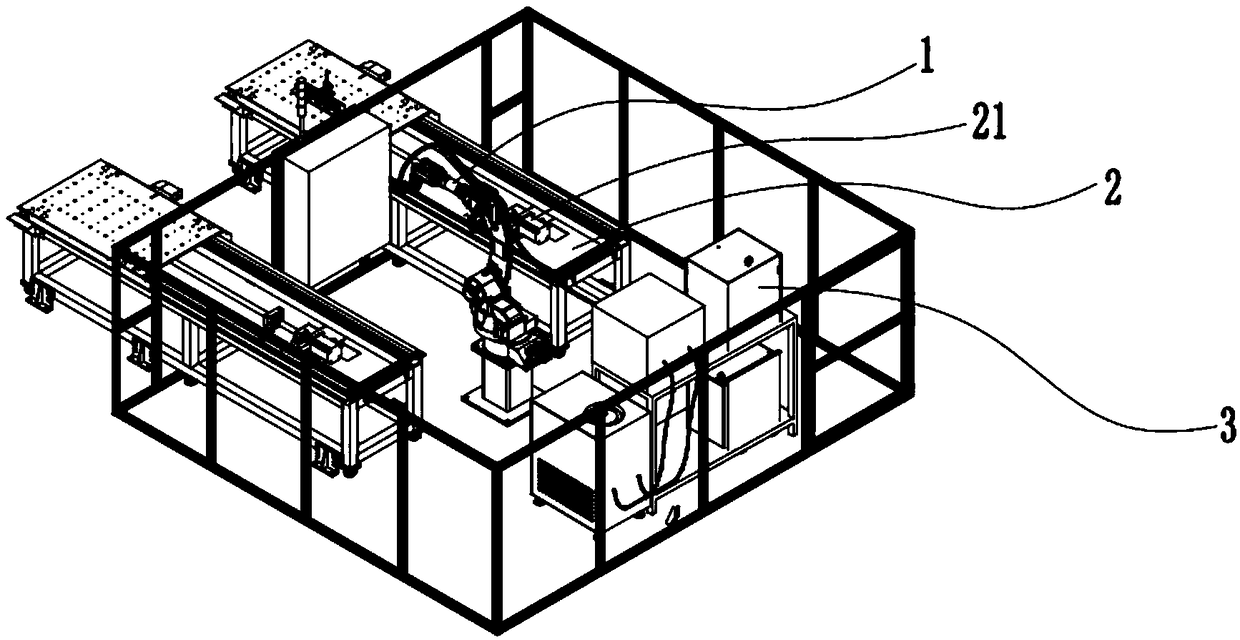

[0032] In order to achieve the purpose of the present invention, as Figure 1-2 As shown, in some embodiments of the integrated control method of a welding machine and a robot arm of a plasma welding equipment of the present invention, it includes the following steps:

[0033] S1: Start up the equipment, robot arm 1 and workbench 2 return to the original point, and the central processing unit judges the current conditions at the same time, the condition is: wait for the cold water temperature to reach the set temperature and then start the welding operation mode;

[0034] S2: The transport line driving mechanism 21 drives and transports the workbench 2 to the designated position inside the peripheral frame. After the position is in place, the sensor detects the signal and transmits it to the central processing unit;

[0035] S3: The central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com