Band steel welding system

A welding system and strip steel technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effect of solving the escape of the tail of the strip steel, stabilizing the quality of the weld, and reducing the probability of weld fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, a strip welding system according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

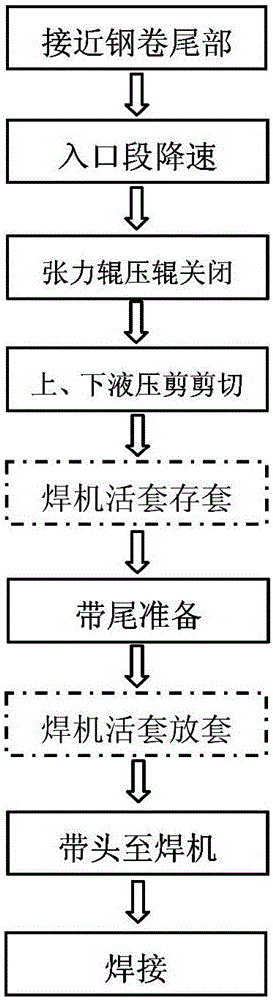

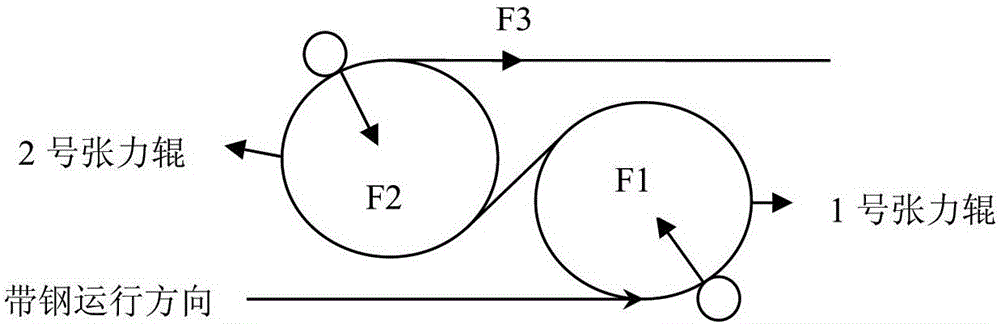

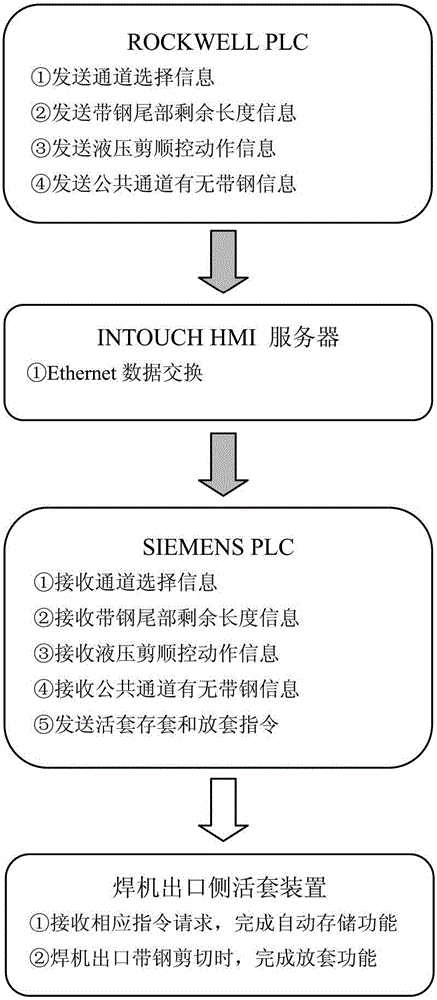

[0014] In the conventional strip welding process, in order to increase the overlapping amount of the strip on the exit side of the welder, when the strip tail is positioned, a certain amount of strip is stored on the exit side of the welder by jogging the tension roller. During this process, the tail of the strip steel may slip into the looper due to the influence of the tension of the looper, especially for products with thicker specifications and thinner specifications, the sliding phenomenon is particularly obvious. The present invention uses the existing function of the looper device at the outlet side of the welding machine to detect and calculate the remaining amount of the tail of the strip during the uncoiling process, and automatically stores the amount of strip steel required for the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com