Wood sliding shock-insulation support

A vibration-isolation bearing and sliding technology, which is applied in the direction of earthquake resistance, building components, building types, etc., can solve the problems of rubber bearings such as short service life, high processing and replacement costs, and complicated processes, and achieve low horizontal stiffness and vertical Effect of high stiffness and isolation of motion components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

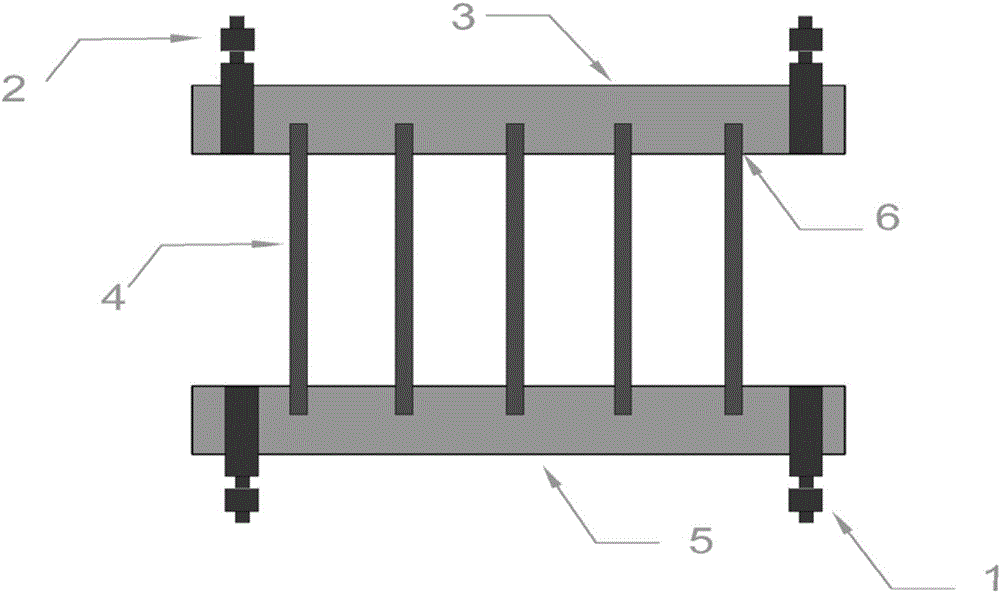

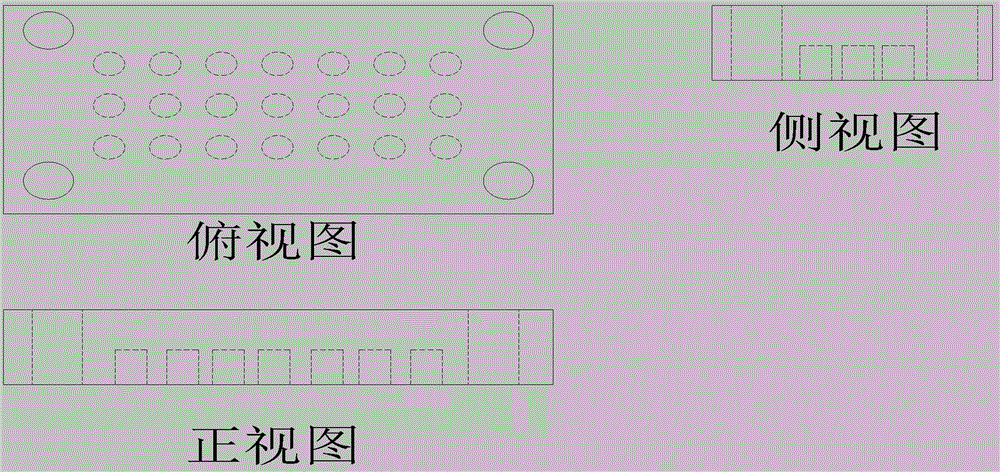

[0014] Such as figure 1 As shown, a wooden sliding shock-isolation support includes an upper connecting plate 3 and a lower connecting plate 5, and upper bolts 2 for connecting with the upper structure are arranged on the four corners of the upper connecting plate 3, and the lower connecting plate 5. Lower bolts 1 for connecting with the lower structure are arranged at the upper four corners. The structures of the upper connecting plate 3 and the lower connecting plate 5 are similar, as figure 2 As shown, several holes are symmetrically opened on the upper connecting plate 3 and the lower connecting plate 5, and wooden strips 4 are inserted in the holes and the joints are reinforced and connected with connecting agent 6, and the wooden strips 4 are located on the upper connecting plate 3 and the lower connecting plate. between 5. The working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com