Construction Method of Tunnel Steel Frame Support

A construction method and steel frame technology, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve the problems of low construction safety and poor overall bearing capacity, and achieve the advantages of convenient process, improved overall bearing capacity and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

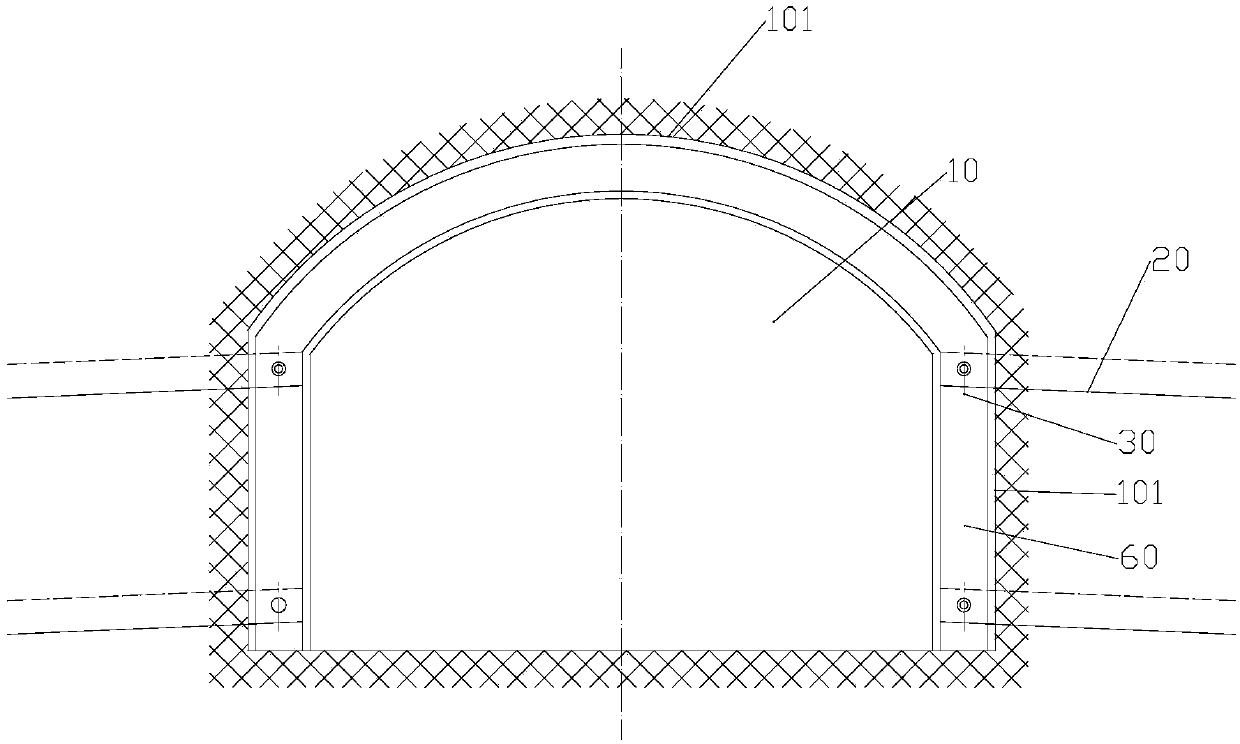

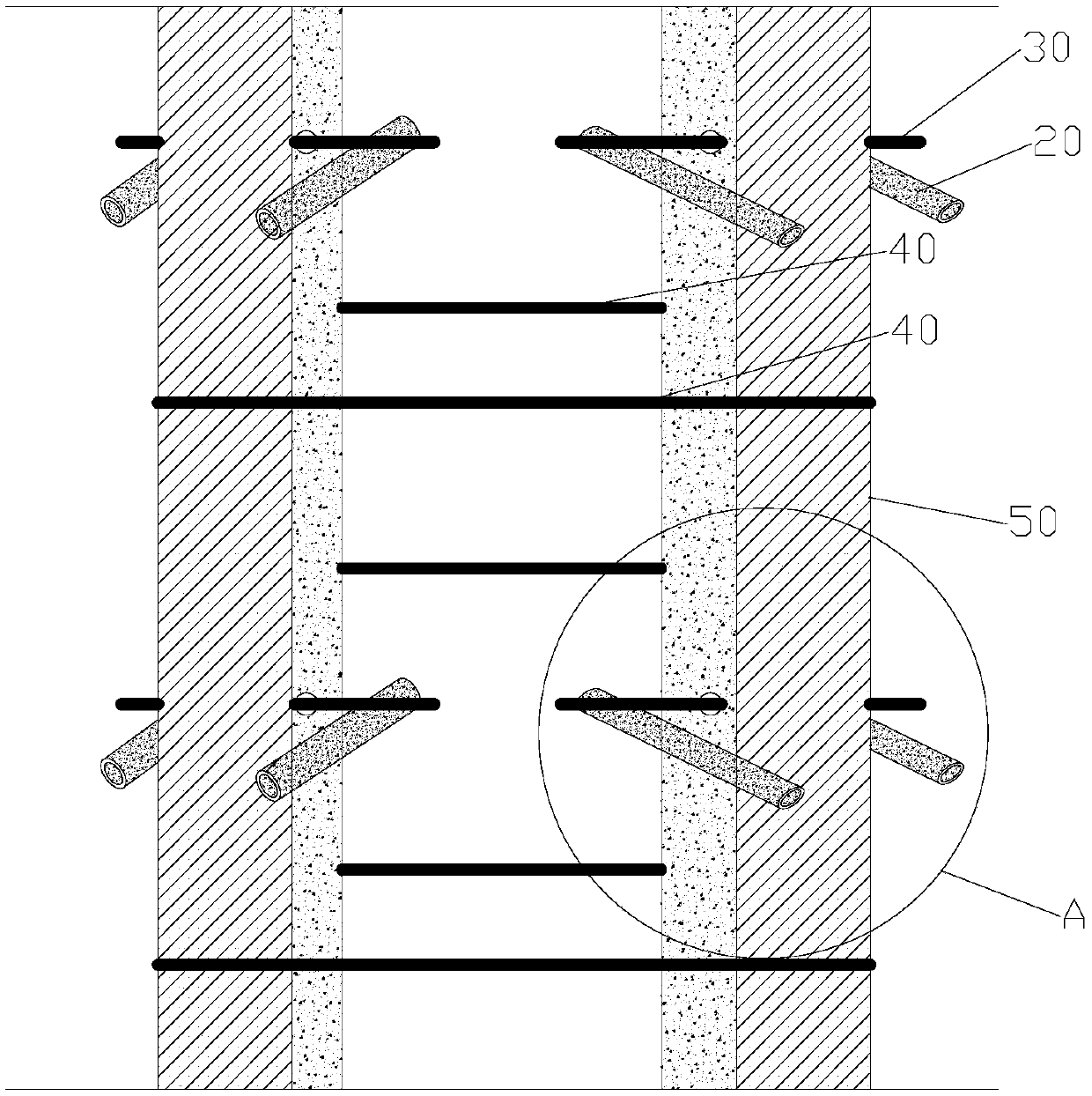

[0028] refer to figure 1 , figure 2 with Figure 5 , the preferred embodiment of the present invention provides a tunnel steel frame support construction method for forming a support steel frame in the tunnel 10 to support surrounding rock, the tunnel steel frame support construction method includes the following steps:

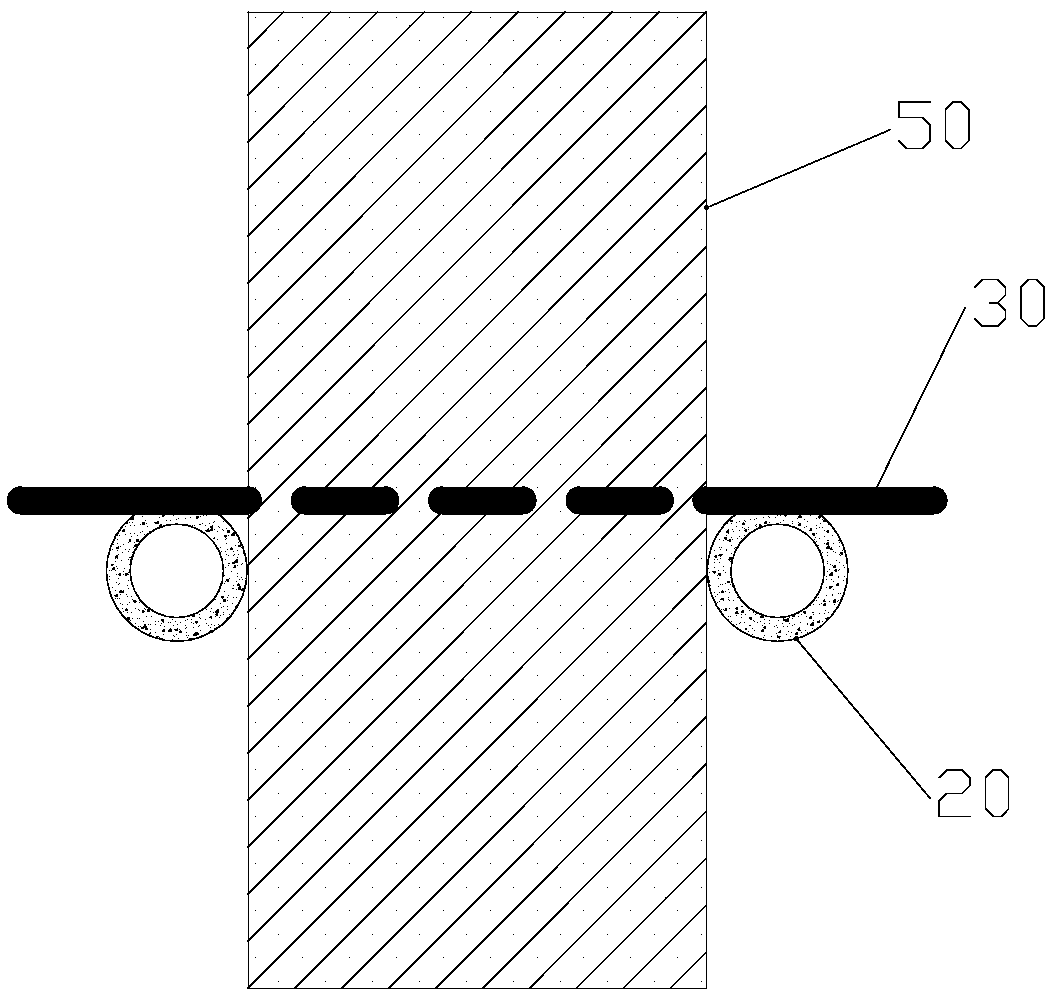

[0029] S10: Preliminary preparation work: S101: According to the tunnel construction drawing, design, process and shape each section of I-beam 50, straight anchor pipe with locking feet 20, connecting steel rods 30 and connecting steel bars 40 to form the supporting steel frame, among which, the straight cylindrical locking feet The anchor pipe 20 is hollow and connected at both ends, and its outer circle is processed with a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com