Piston assembly with weight reducing structure

A piston assembly, piston technology, applied in the direction of piston, engine components, machine/engine, etc., can solve problems such as cylinder pulling, jamming, piston pin and pin hole wear, etc., to reduce relative wear, relatively light weight, easy to lubricate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

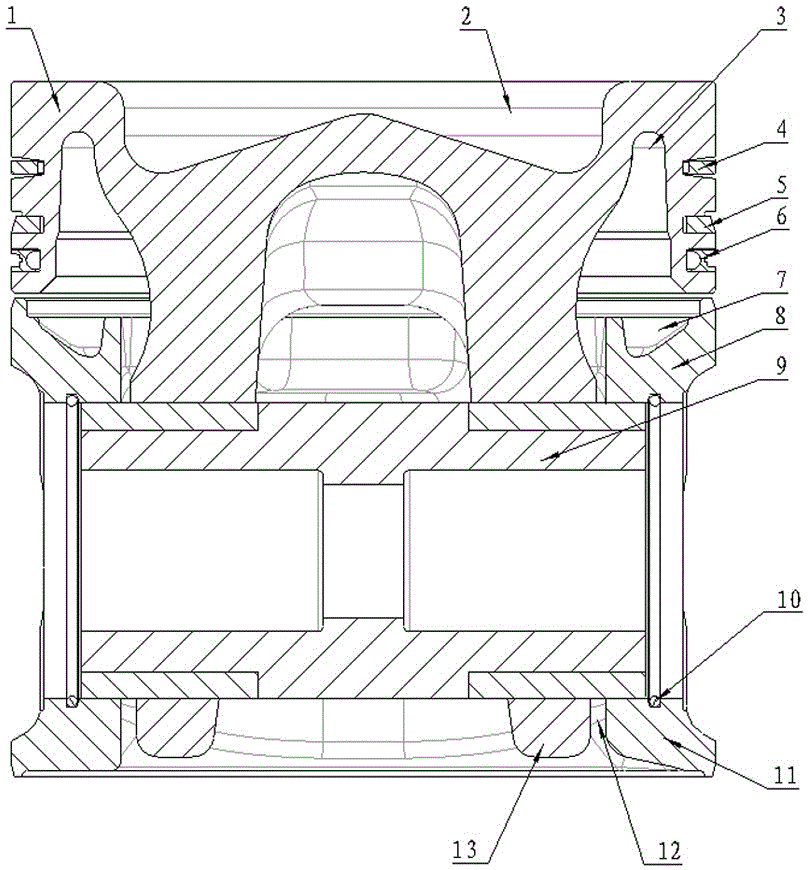

[0019] To make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the following is attached figure 1 The present invention will be further described in detail with specific embodiments.

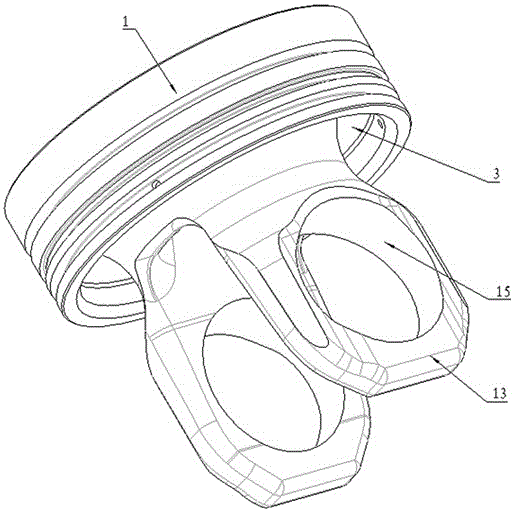

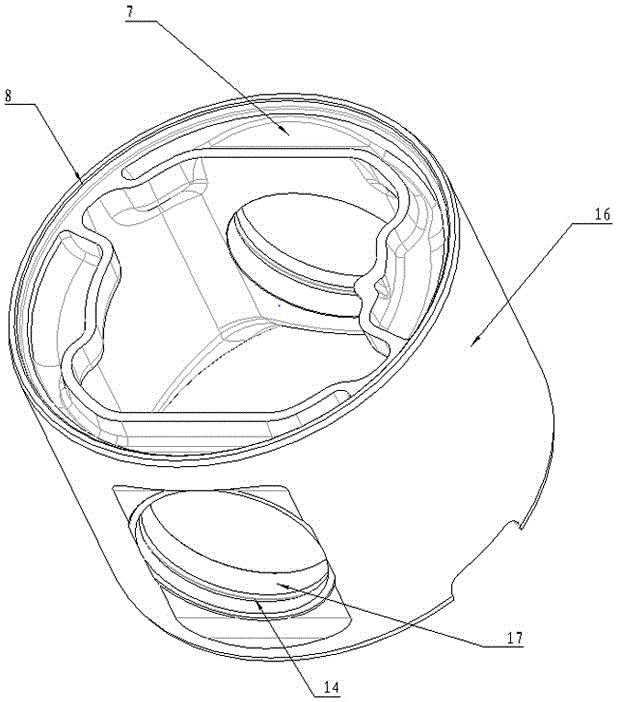

[0020] In the weight-reducing structure of the piston assembly in this embodiment, the piston includes a piston body 1 with a steel integral structure and a sleeve 8 made of aluminum alloy. The piston body 1 has an upper groove 3 and a pin seat 13, and the sleeve 8 There is a lower groove 7 on the upper side, and a molybdenum disulfide coating 16 is also provided outside the sleeve 8, which can reduce initial wear. The piston body 1, the combustion chamber 2 and the cylinder head constitute the engine combustion chamber 2, and the gas is burned in the engine combustion chamber 2.

[0021] The sleeve 8 is sleeved outside the piston body 1, two opposite pin holes 15 are provided on the pin seat 13, two opposite pin holes 17 are provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com