A level pendulum prism pasting tool and its use method

A level meter and prism technology, which is applied in the field of level pendulum prism sticking tooling, can solve the problems of poor universal type of tooling, affect the image quality of the instrument, and high work intensity, and achieve the effects of reducing the initial curing time, reducing the bonding stress, and reducing the work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

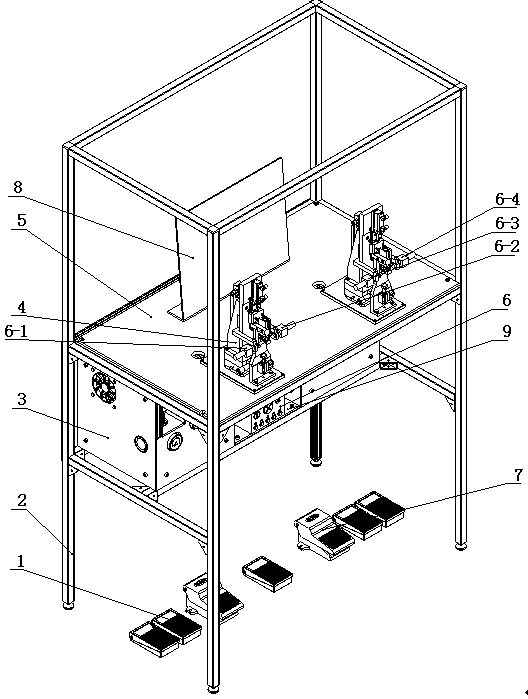

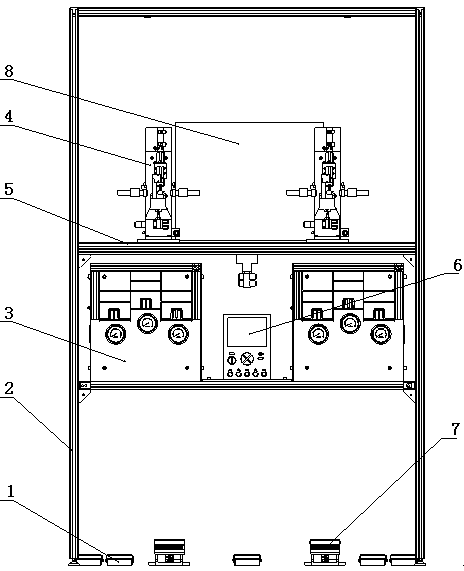

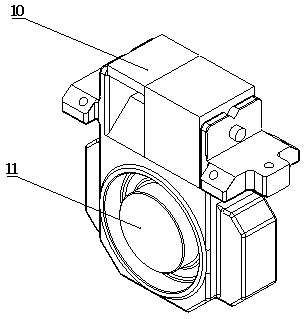

[0050] like figure 1 , figure 2As shown, a level pendulum prism pasting tool includes a foot switch 1, a table body frame 2, an electrical box 3, a pendulum prism pasting body 4, a table board 5, a UV curing machine 6, a pedal pneumatic valve 7, and a process document support 8 , the support plate 9 and the control system, wherein the table plate 5 is fixed to the upper layer of the table body frame 2 by screws, the electrical box 3 and the support plate 9 are fixed to the lower layer of the table body frame 2 by screws, and the main body of the UV curing machine 6 is placed on the support plate 9 , the pendulum prism pasting body 4 is fixed on the table board 5 with screws through the reserved mounting holes of the table board 5, the process file support 8 is placed on the table board 5, and the foot switch 1 is connected to the control system for the action control inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com