Oxidation-reduction roasting integrated rotary hearth furnace

A rotary hearth furnace and roasting technology, applied in the furnace, charge, furnace type, etc., can solve the problems of uneven heating of materials, poor direct reduction effect, single function, etc., and achieve low cost, good reduction effect, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solution of the present invention and its advantages in various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

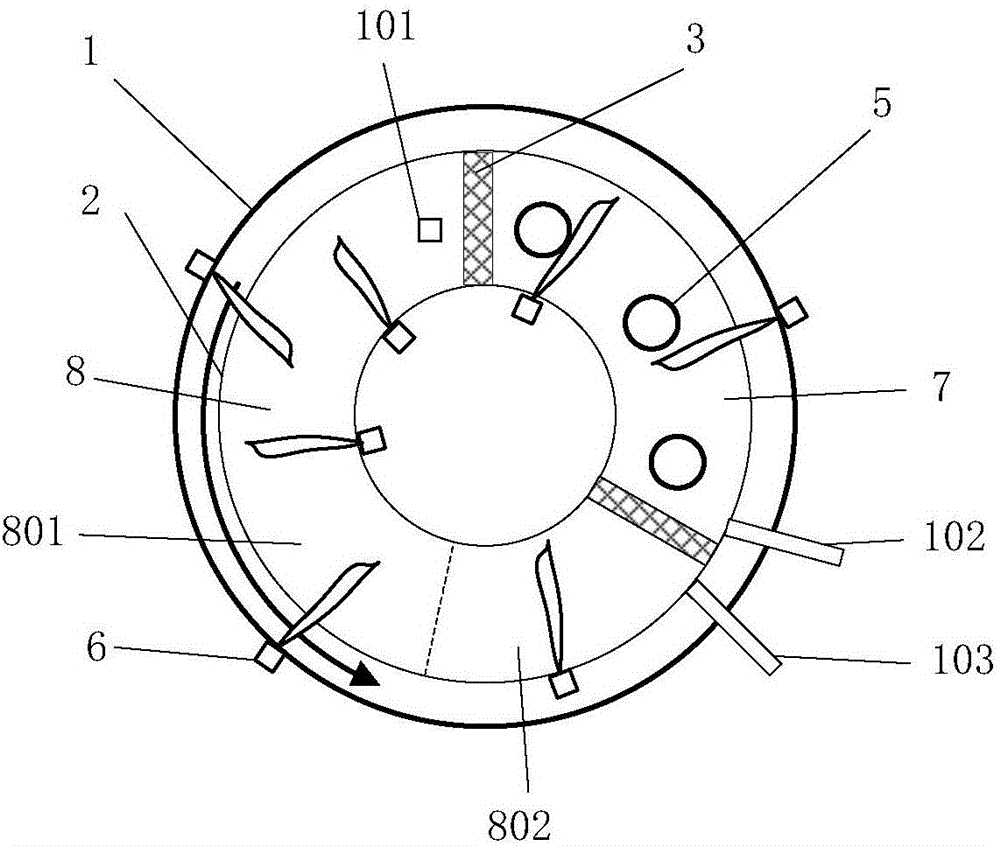

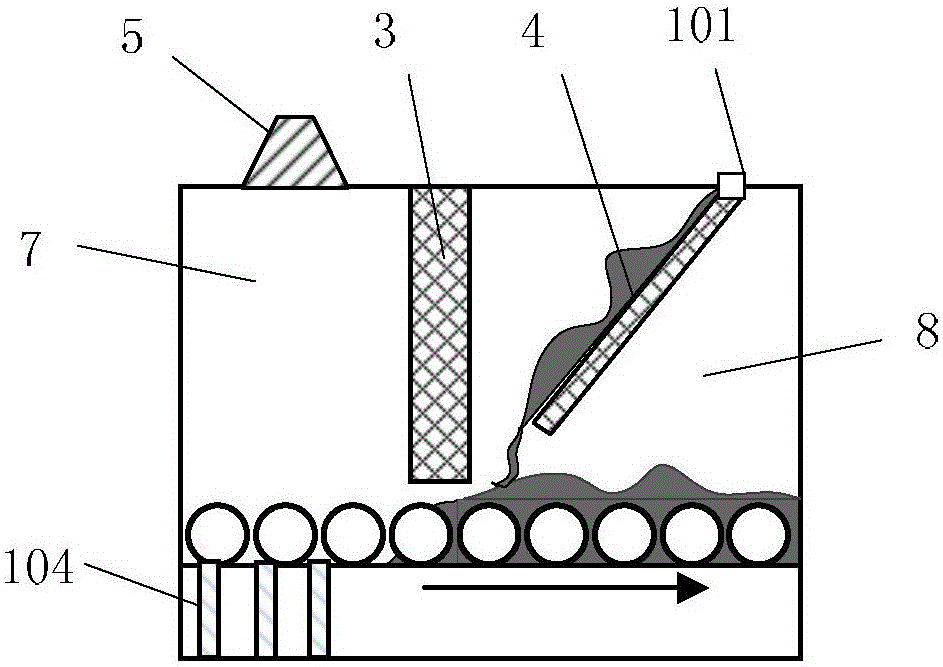

[0033] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides an oxidation-reduction roasting integrated rotary hearth furnace, including: a furnace body 1 , a furnace bottom 2 , a retaining wall 3 , a chute 4 , a flue 5 and a burner 6 .

[0034] The furnace body 1 includes an outer side wall, a furnace roof and an inner side wall, the outer side wall is connected to the inner side wall through the furnace roof, and the cross-sectional area of the furnace body is ring-shaped.

[0035] The furnace bottom 2 is annular and located below the furnace body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com