Method for low-cost cleaning treatment of waste lithium ion battery cathode material

A lithium-ion battery and cathode material technology, which is applied in the field of low-cost clean treatment of waste lithium-ion battery cathode materials, can solve the problems of difficult utilization of composite cathode materials and difficult reuse of cathode materials, and achieves a significant and reliable separation and recovery effect The effect of technical support and efficient dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

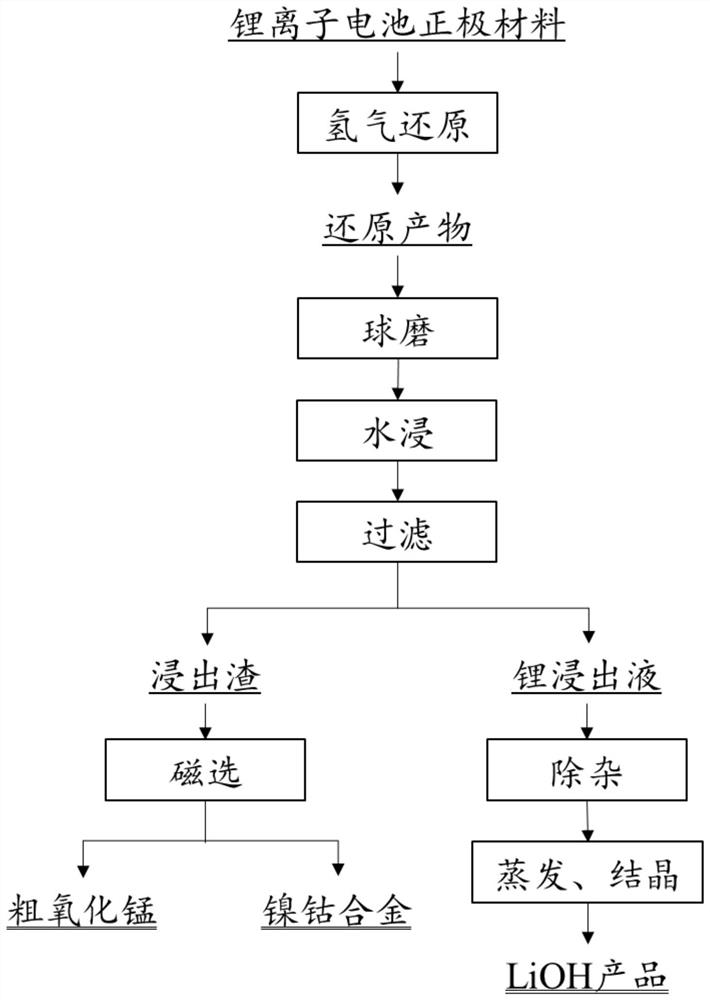

[0037] A kind of method of the present invention's low-cost clean treatment waste lithium ion battery anode material, its process flow chart is as follows figure 1 shown, including the following steps:

[0038] (1) The waste lithium battery positive electrode material obtained after pretreatment (the mixture of nickel-cobalt lithium manganese oxide composite positive electrode material and nickel manganese oxide lithium composite positive electrode material) is dried, then put into the reduction furnace, under argon protective atmosphere The reduction was carried out by introducing hydrogen gas (the flow rate of hydrogen gas was 100ml / min), the reduction temperature was 600° C., and the reduction time was 0.5 h.

[0039] (2) Putting the reduced product obtained in step (1) into a ball mill for ball milling to obtain reduced product powder with a particle size of 1-200 μm.

[0040] (3) The reduced product powder obtained in step (2) is immersed in water at a temperature of 50°...

Embodiment 2

[0045] A kind of method of the present invention's low-cost clean treatment waste lithium ion battery anode material, its process flow chart is as follows figure 1 shown, including the following steps:

[0046] (1) Dry the waste lithium battery cathode material (a mixture of lithium manganate cathode material and nickel-cobalt lithium aluminate composite cathode material) obtained after pretreatment, and put the dried waste lithium ion battery cathode material into the reduction furnace , under the protective atmosphere of argon, the reduction was carried out by introducing hydrogen gas (the hydrogen flow rate was 100ml / min), the reduction temperature was 700° C., and the reduction time was 1 h.

[0047] (2) Putting the reduced product obtained in step (1) into a ball mill for ball milling to obtain reduced product powder with a particle size of 1-200 μm.

[0048] (3) Water immerse the reduced product powder obtained in step (2), the water immersion temperature is 60°C, the w...

Embodiment 3

[0053] A kind of method of the present invention's low-cost clean treatment waste lithium ion battery anode material, its process flow chart is as follows figure 1 As shown, the method includes the following steps:

[0054] (1) The waste lithium battery cathode material obtained after pretreatment (the mixture of lithium cobalt oxide cathode material and nickel cobalt manganate lithium cathode material) is dried, and the dried waste lithium ion battery cathode material is put into a reduction furnace, Under the protective atmosphere of argon gas, hydrogen gas was introduced for reduction (hydrogen gas flow rate was 100ml / min), the reduction temperature was 800°C, and the hydrogen gas reduction time was 2h.

[0055] (2) Putting the reduced product obtained in step (1) into a ball mill for ball milling to obtain reduced product powder with a particle size of 1-200 μm.

[0056] (3) Water immerse the reduced product powder obtained in step (2), the water immersion temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com