Preparation method of copper/graphene catalyst

A graphene and catalyst technology, applied in the field of copper/graphene catalyst preparation, can solve the problems of high process equipment requirements, strong reducing agent toxicity, etc., and achieve the effects of good reduction effect, thorough reduction effect and high catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

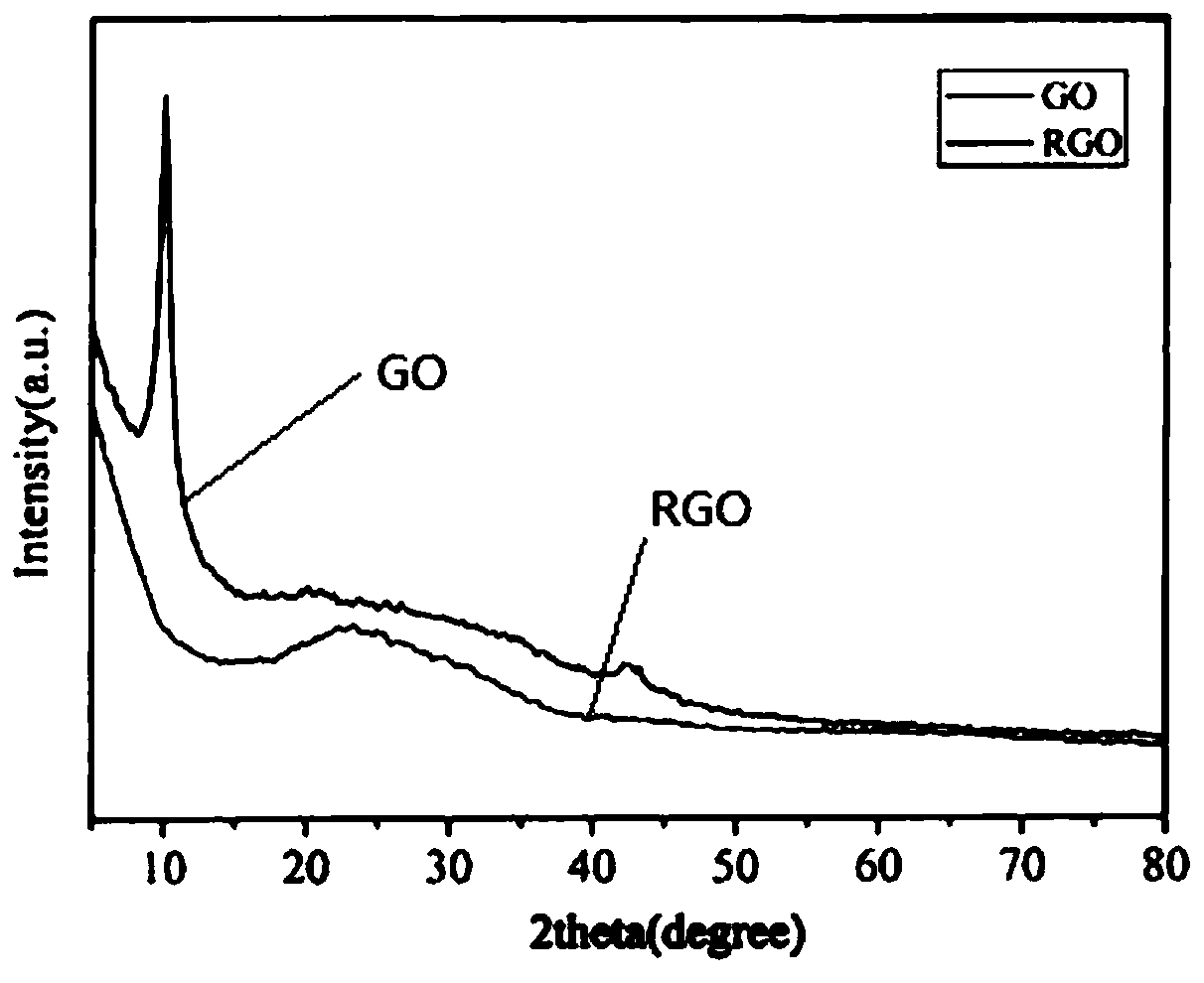

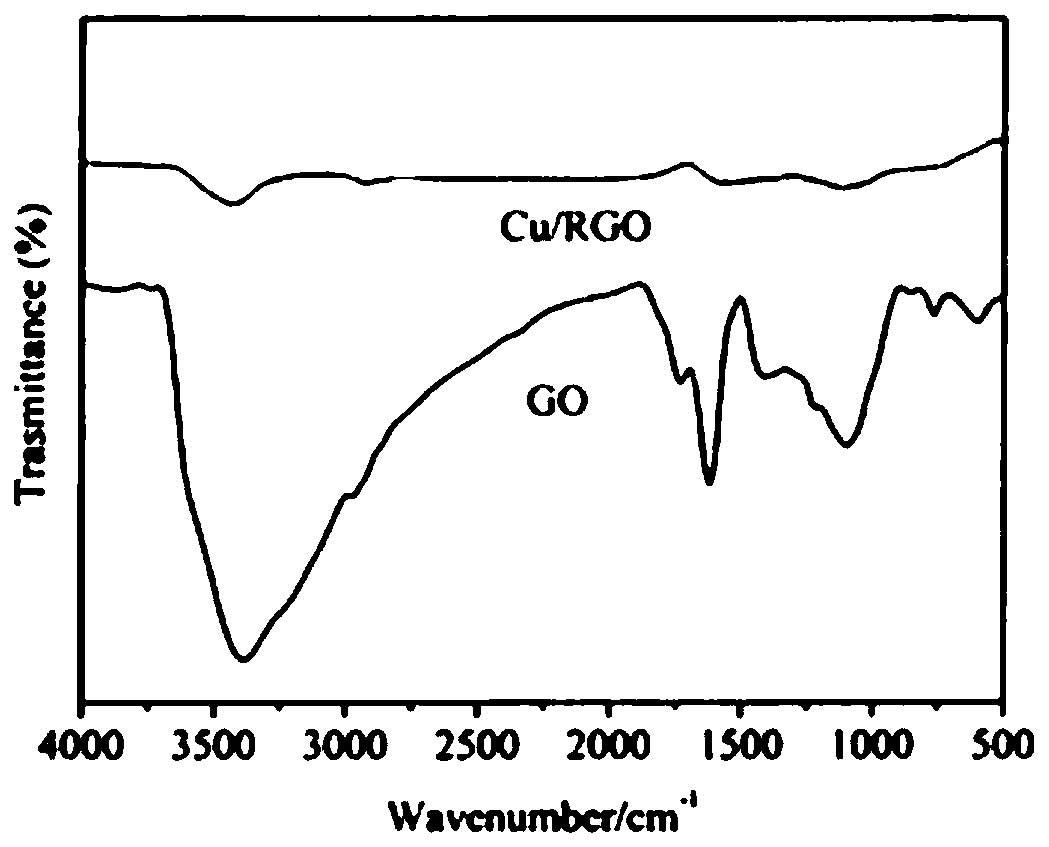

[0034] The preparation of graphene catalyst, its preparation method is as follows:

[0035] (1) Weigh 1.0g graphene flakes and add it to the mixed solution of concentrated sulfuric acid and concentrated phosphoric acid with a volume ratio of 9:1, mechanically stir for 30min at a temperature of 0°C to 5°C, the reaction solution is a black suspension, and then Weigh 6.0g of potassium permanganate, and feed slowly at a speed within 20min. At this time, the solution turns from black to dark green, and then keep the temperature at 50°C for 15h. At this time, the reaction solution is pinkish purple. After cooling, slowly add 140ml of deionized water to ensure that the temperature is within the range of 60°C, then add 8ml of hydrogen peroxide into the reaction bottle, and stir mechanically for 10 minutes. At this time, the reaction solution is golden yellow, then wash with hydrochloric acid to remove sulfate radicals, and then wash with deionized water To neutrality, the precipitate ...

Embodiment 2

[0047] The preparation of graphene catalyst, its preparation method is as follows:

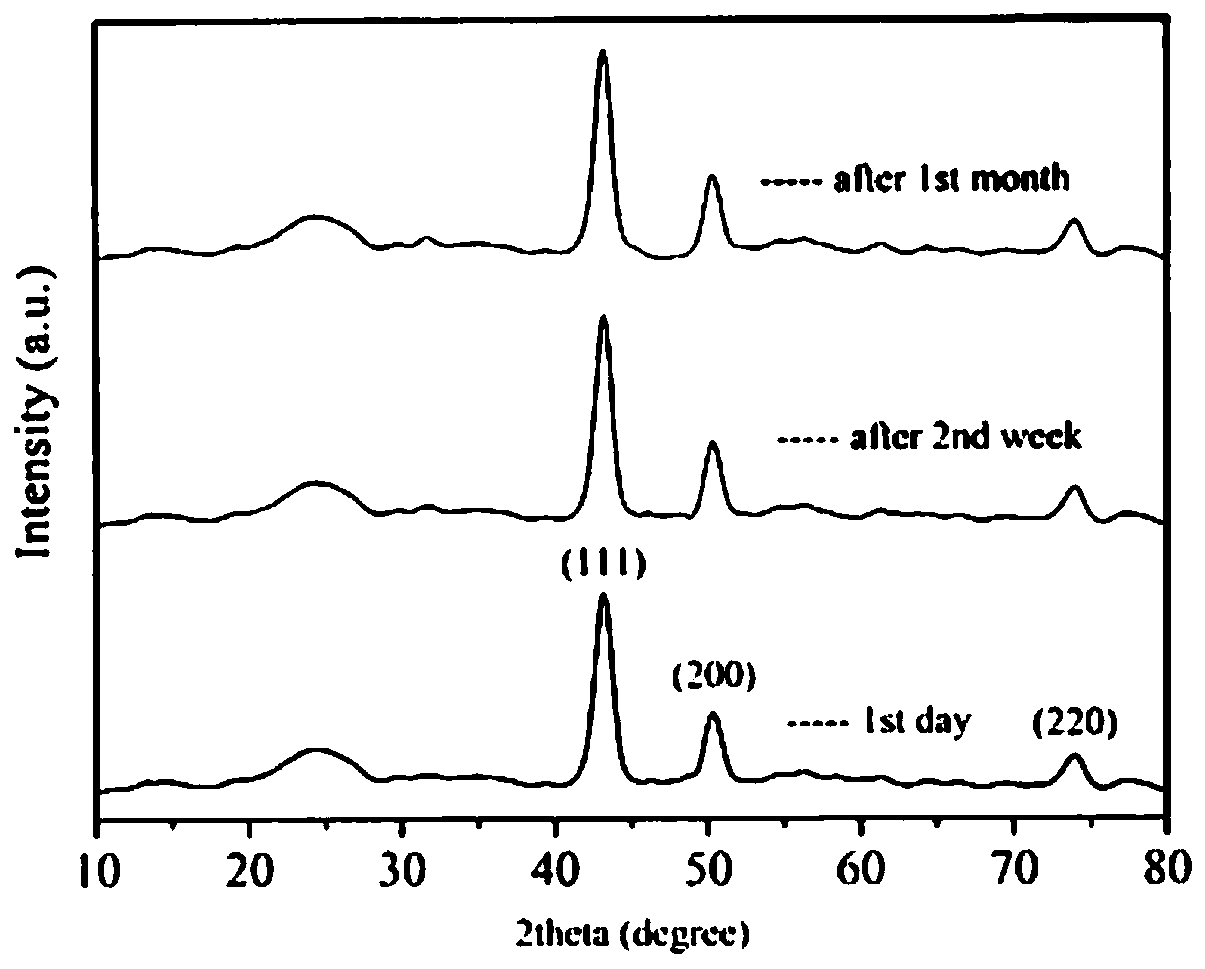

[0048] Step (1) is with embodiment 1. (2) Weigh 200.0 g of graphene oxide and add it to ultrasonic dispersion in N-methylpyrrolidone for 2 h, then mechanically stir for 10 min, adjust to pH=10 with NaOH solution, after mechanically stirring for 10 min, add 200.0 g of ascorbic acid, and mechanically stir for 30 min . In addition, 68g of copper sulfate pentahydrate was weighed and dissolved in 4L of distilled water to form a copper sulfate solution with a concentration of 17mg / ml, and then the copper sulfate solution was slowly added dropwise to the reaction solution, and reacted at 80°C for 2h; after cooling Add 100L of distilled water, let it stand to remove the upper layer, wash and centrifuge three times with distilled water and absolute ethanol in turn, collect the precipitate by centrifugation, and vacuum dry at 50°C for 16 hours to obtain a black copper / graphene solid. Measure the copper...

Embodiment 3

[0050] The preparation of graphene catalyst, its preparation method is as follows:

[0051] Step (1) is with embodiment 1. (2) Weigh 200.0 g of graphene oxide and add it to ultrasonic dispersion in N-methylpyrrolidone for 2 h, then mechanically stir for 10 min, adjust to pH=10 with NaOH solution, after mechanically stirring for 10 min, add 280.0 g of ascorbic acid, and mechanically stir for 30 min . In addition, 88g of copper sulfate pentahydrate was weighed and dissolved in 4L of distilled water to form a copper sulfate solution with a concentration of 22mg / ml, and then the copper sulfate solution was slowly added dropwise to the reaction solution and reacted at 120°C for 3 hours; after cooling Add 100L of distilled water, let it stand to remove the upper layer, wash and centrifuge three times with distilled water and absolute ethanol in turn, collect the precipitate by centrifugation, and vacuum dry at 50°C for 16 hours to obtain a black copper / graphene solid. Measure the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com