Self-adapting eyeglass lens cleaning and dust removal device

A technology for dust removal devices and spectacle lenses, which is applied in the directions of glasses/protective glasses, glasses/goggles, optics, etc., can solve the problems of unstable cleaning quality, time-consuming and laborious, poor cleanliness, etc., and achieves clean cleaning, simple device structure, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

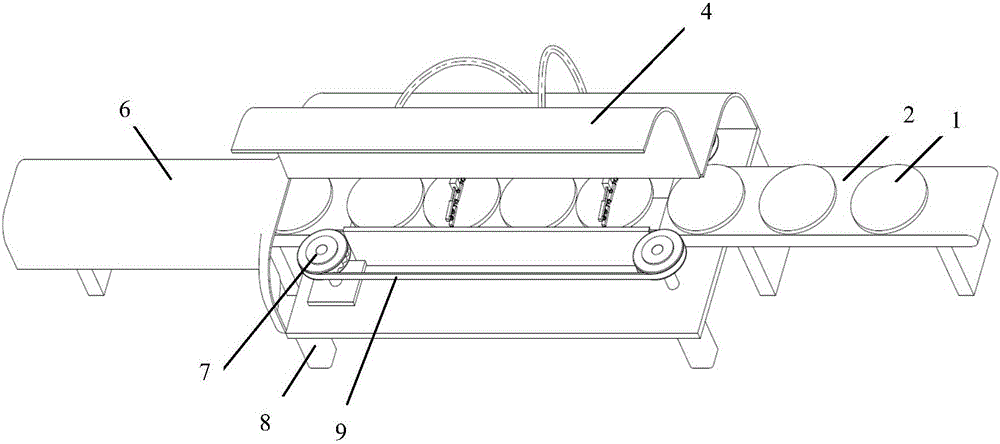

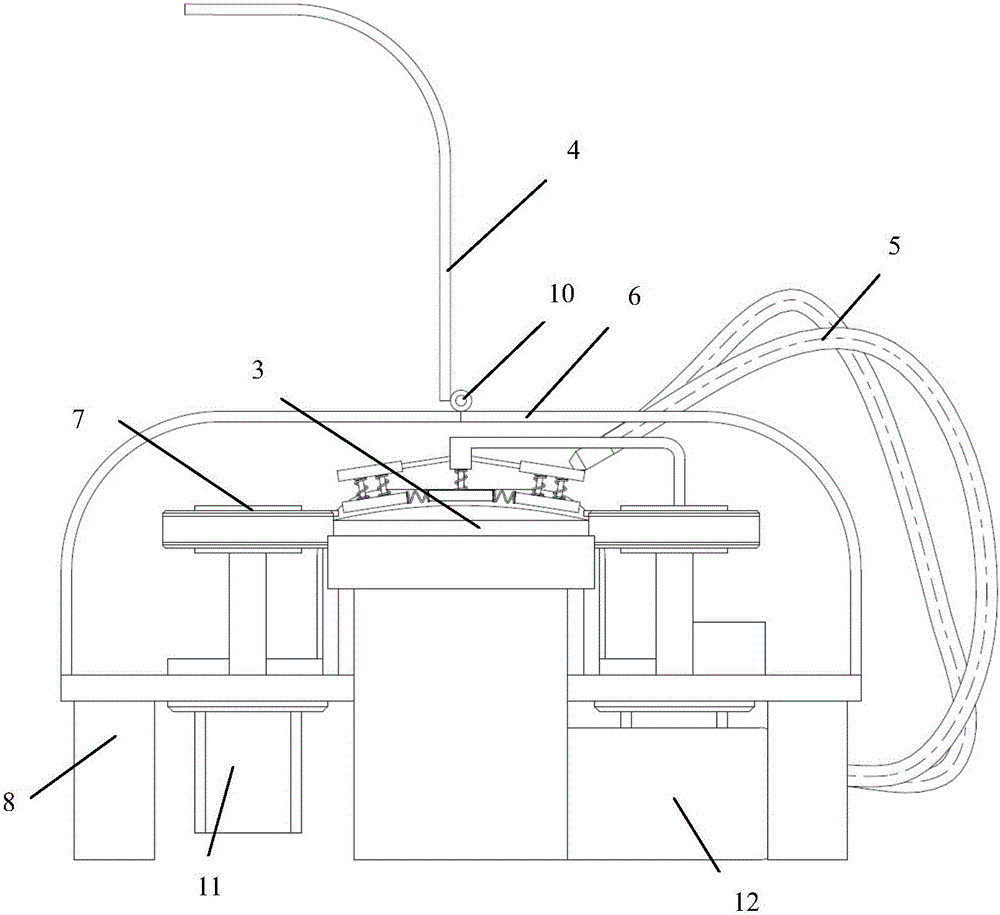

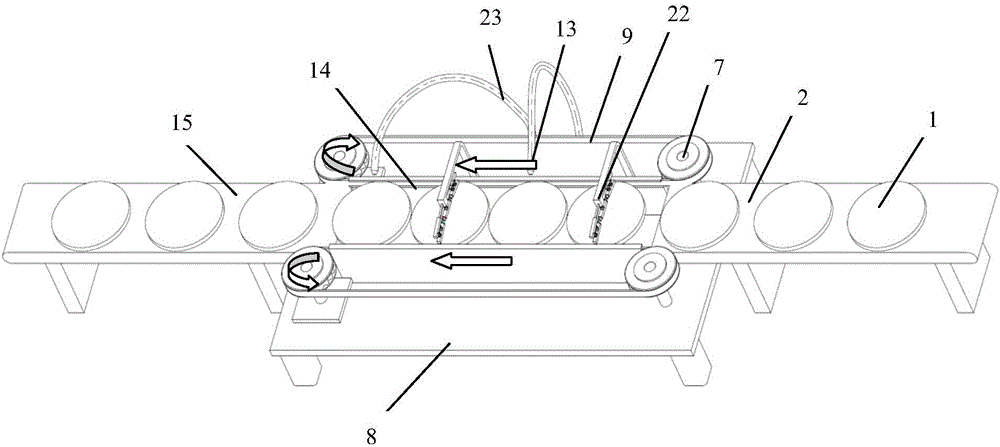

[0024] combined with figure 1 The self-adaptive spectacle lens cleaning and dust removal device provided by the present invention comprises a frame 8, a first motor 11, a second motor 16, a lens feeding conveyor belt 2, a lens blanking conveyor belt 15, a cleaning mechanism 22, a lens dust removal device 5, a belt Wheel 7 and belt 9; four pulleys 7 are symmetrically installed on the frame 8; belts 9 are installed on the pulley 7, and a lens feeding conveyor belt is provided on the frame 8 along the entrance of the installation direction of the belt 9 2. The outlet end is provided with a lens unloading conveyor belt 15; the lens loading conveyor belt 2 and the lens unloading conveyor belt 15 are placed between the belts 9; the two belts at the outlet end of the frame 8 along the installation direction of the belt 9 The axle of wheel 7 is connected with the output shaft of first motor 11, the second motor 16 respectively by coupling; Described first motor 11, the second motor 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com