Robot troubleshooting system and method

A technology for troubleshooting and robots, applied in the field of robots, can solve problems such as increasing the difficulty of robot maintenance, and achieve the effects of facilitating centralized processing, facilitating usage, and reducing technical thresholds and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

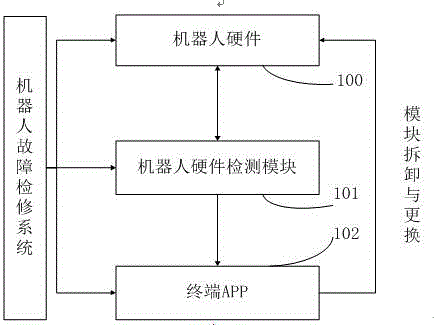

[0036] see figure 1 , figure 1 It is a structural schematic diagram of the robot troubleshooting system in this embodiment. This embodiment provides a robot troubleshooting system, including robot hardware 100, robot hardware detection module 101 and terminal APP 102, the output end of the robot hardware 100 is connected to the input end of the robot hardware detection module 101, the The output terminal of the robot hardware detection module 101 is connected with the terminal APP 102 .

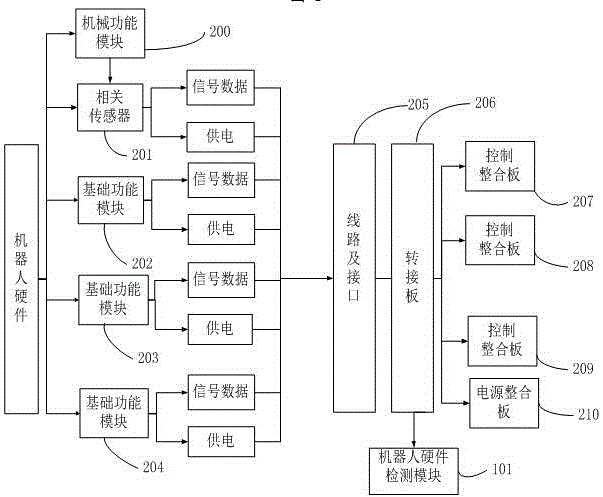

[0037] see figure 2 , figure 2 It is a structural block diagram of the robot hardware in this embodiment. In this example, the robot hardware 100 is divided into mechanical function modules 200, such as robot skeleton and pure mechanical structure, etc., which are combined with related sensors 201 into a kind of interface functional parts; basic function modules include basic function modules 202, basic function modules Module 203 and basic function module 204, etc., in addition to ret...

Embodiment 2

[0047] The difference between this embodiment and the previous embodiment is:

[0048] The terminal APP is an application program installed in the mobile phone. The terminal APP realizes fault location and display of graphic and text maintenance plan through one-dimensional code image recognition. Operators perform maintenance operations according to the graphic and text maintenance plan, and perform module removal and replacement , maintenance can be realized.

Embodiment 3

[0050] The difference between this embodiment and the previous embodiment is:

[0051] The terminal APP is an application program installed in the mobile phone. The terminal APP realizes fault location and graphic and text maintenance plan display through Bluetooth communication. The operator performs maintenance operations according to the graphic and text maintenance plan, and performs module removal and replacement. Achieve repairs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com