Square aluminum electrolytic capacitor based on gel electrolyte and preparation method thereof

An aluminum electrolytic capacitor and gel electrolyte technology, applied in the field of electronics, can solve the problems of low volume utilization rate of flat space, ineffective use of space, easy accumulation of heat in capacitors, etc., and achieve easy control of production operation and temperature, and low freezing point. , mixing and cooling effect easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

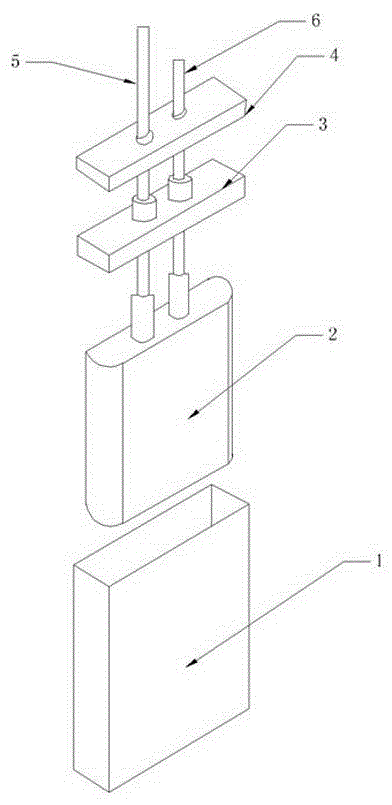

[0042] Such as figure 1 A square aluminum electrolytic capacitor based on gel electrolyte is shown, including a square aluminum shell 1, a flat oval winding core pack 2, a rubber plug 3 and a cover plate 4, the rubber plug 3 and the cover plate 4 will be The core package 2 is sealed in the square aluminum shell 1; the aluminum stems of the positive electrode lead 5 and the negative electrode lead 6 of the core package 2 are sealed and connected with the rubber plug through UV glue or epoxy thermosetting glue; the inside of the core package 2 and the square A gel-like electrolyte is formed between the aluminum shells 1; the gel-like electrolyte is a gel-like polymer compound obtained by polymerization of the solution system I and the solution system II under the initiation of an initiator; the solution system I and the solution system II The mixing ratio is 1:4-4:1; the solution system II includes 85%-95% polymerized monomers, 2%-20% crosslinking agents and 0.1%-10% initiators,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com