Connecting apparatus and mounting method for 110kV outdoor cable terminal

A connecting device and outdoor cable technology, applied in the direction of connection, connection insulation, connection contact material, etc., can solve the problems of increased contact resistance, heat generation at the junction of protruding terminal clamps, small contact area, etc., to reduce the contact area , Avoid relative movement, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

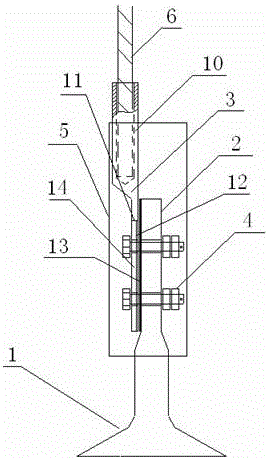

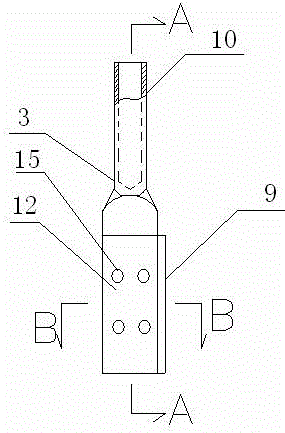

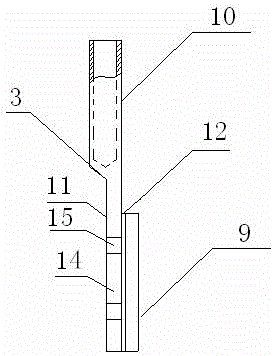

[0043] Example 1: Reference Figure 1-7 . A connection device for 110kV outdoor cable terminals in this embodiment, including 110kV outdoor fully prefabricated dry-type cable terminals 1, copper terminals 2, copper-aluminum transition equipment clamps 3, fasteners 4, and cylindrical heat shrinkable tubes 5 , wire jumper 6, copper wing plate 9, crimping tube 10, copper-aluminum transition plate 11, copper surface layer 12, calendered copper foil 13, aluminum substrate 14, through hole 15.

[0044] The contact area of the copper terminal 2 is 16 to 20 times the cross-sectional area of the 110kV cable, and the contact area of the copper surface layer 12 of the copper-aluminum transition equipment clamp 3 is the same as that of the copper terminal 2, thus completely solving the theoretical contact problem. The problem is that the area is sufficient but the contact area is not enough after operation. Both the copper terminal 2 and the copper-aluminum transition equipment cl...

Embodiment 2

[0047] For the installation method of a 110kV outdoor cable terminal in this embodiment, refer to the attached Figure 1-7 , during installation, the cylindrical heat-shrinkable tube 5 is pre-set on the copper-aluminum transition equipment clamp 3 and the wire jumper 6 with the copper wing plate 9; secondly, the copper wing plate 9 of the copper-aluminum transition equipment clamp 3 is located on the , close to one side of the copper terminal 2, place a rolled copper foil 13 between the copper terminal 2 and the copper surface layer 12 of the copper-aluminum transition equipment clamp 3, and then fasten the copper terminal with a fastener 4 2. Rolled copper foil 13 and copper-aluminum transition equipment clamp 3 with copper wings 9; again, heat the cylindrical heat-shrinkable tube 5 to shrink and seal the copper terminal 2 and the copper-aluminum transition with copper wings 9 in turn The equipment clamp 3 and stainless steel anti-loosening bolts, the cylindrical heat shrinka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com