Motor Oil Cooling System

A technology for oil cooling system and motor cooling, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing the structural complexity and processing requirements of the gearbox casing, and achieves simplification of structural design and manufacturing and reduction of processing. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

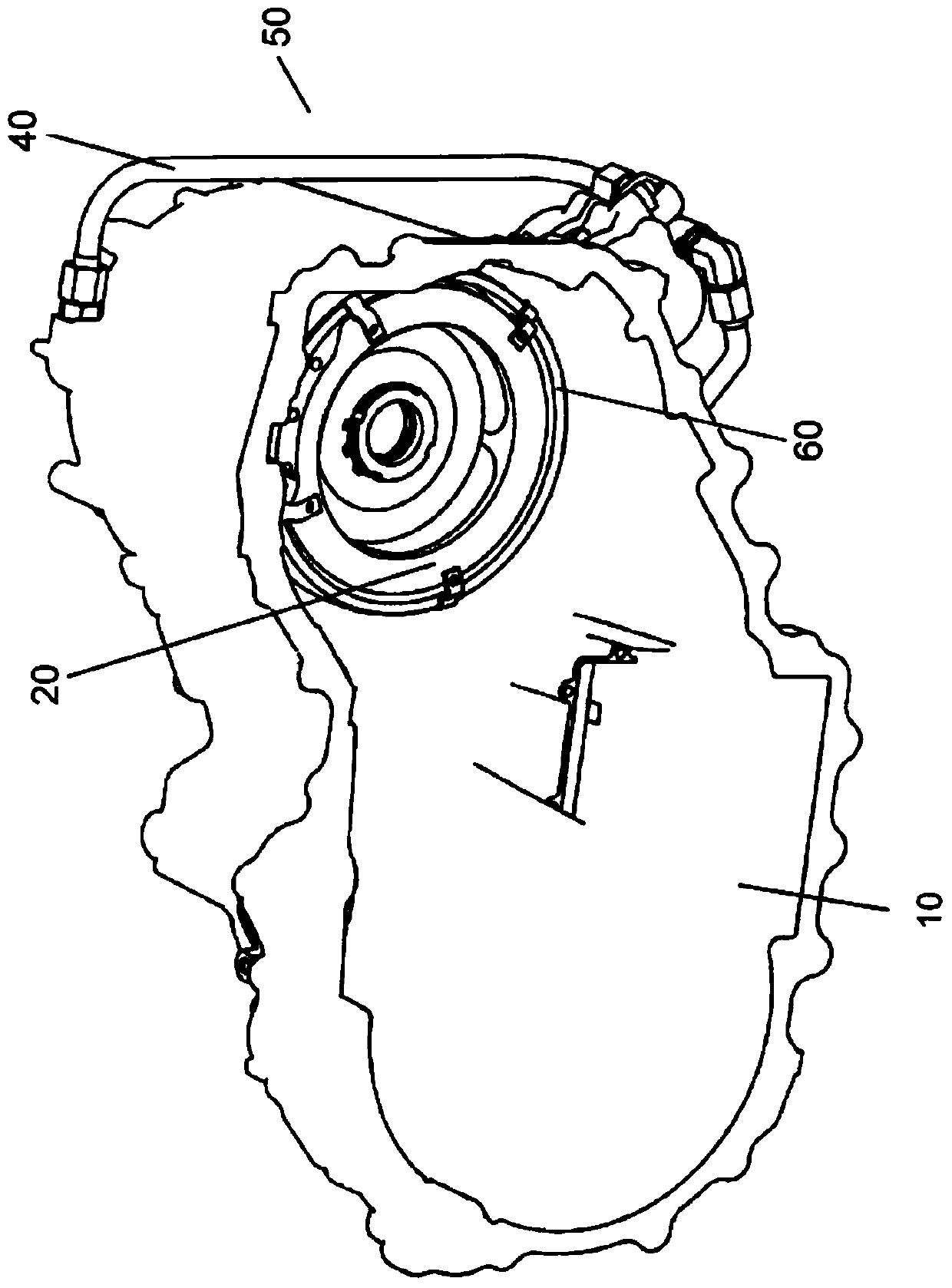

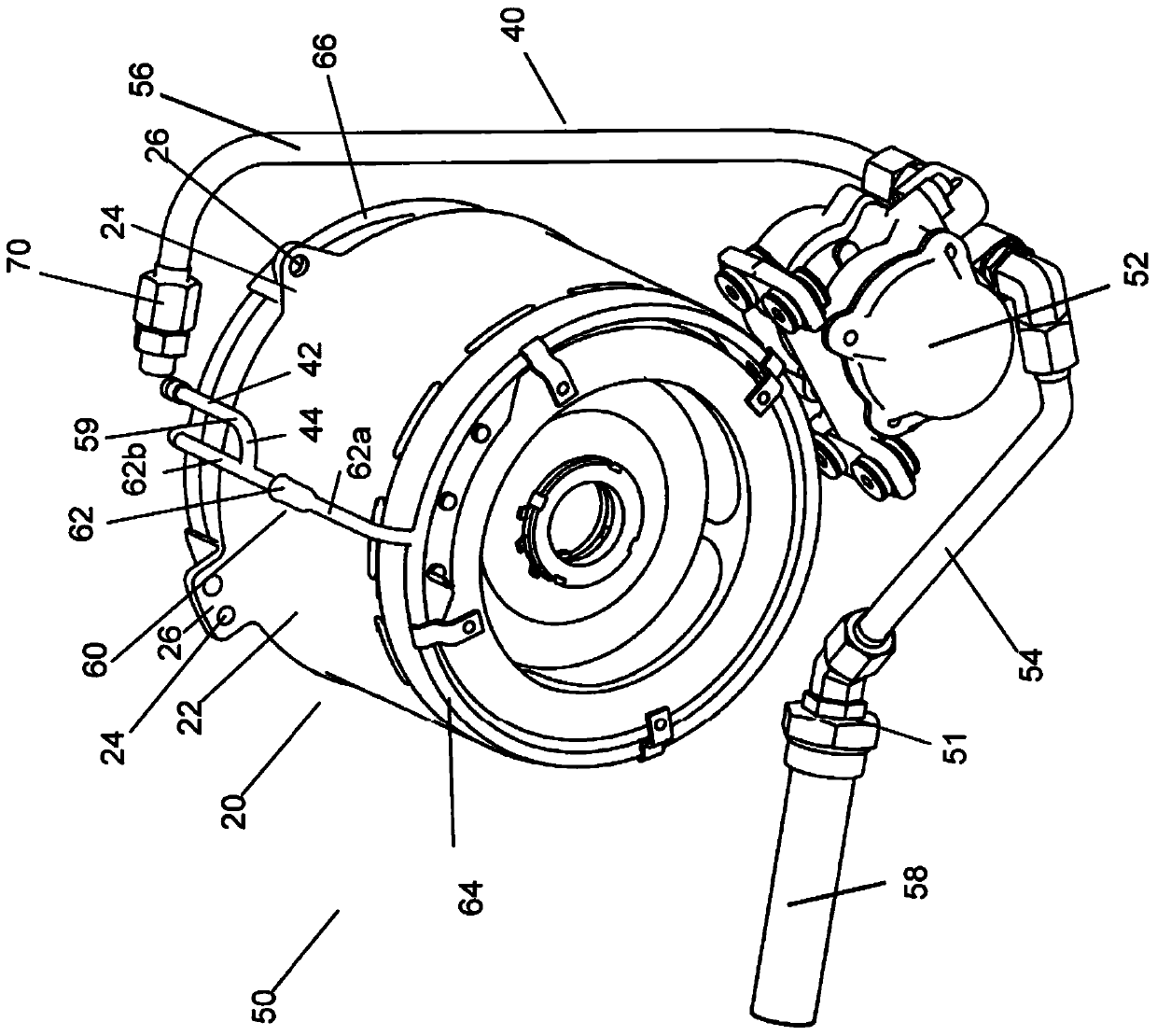

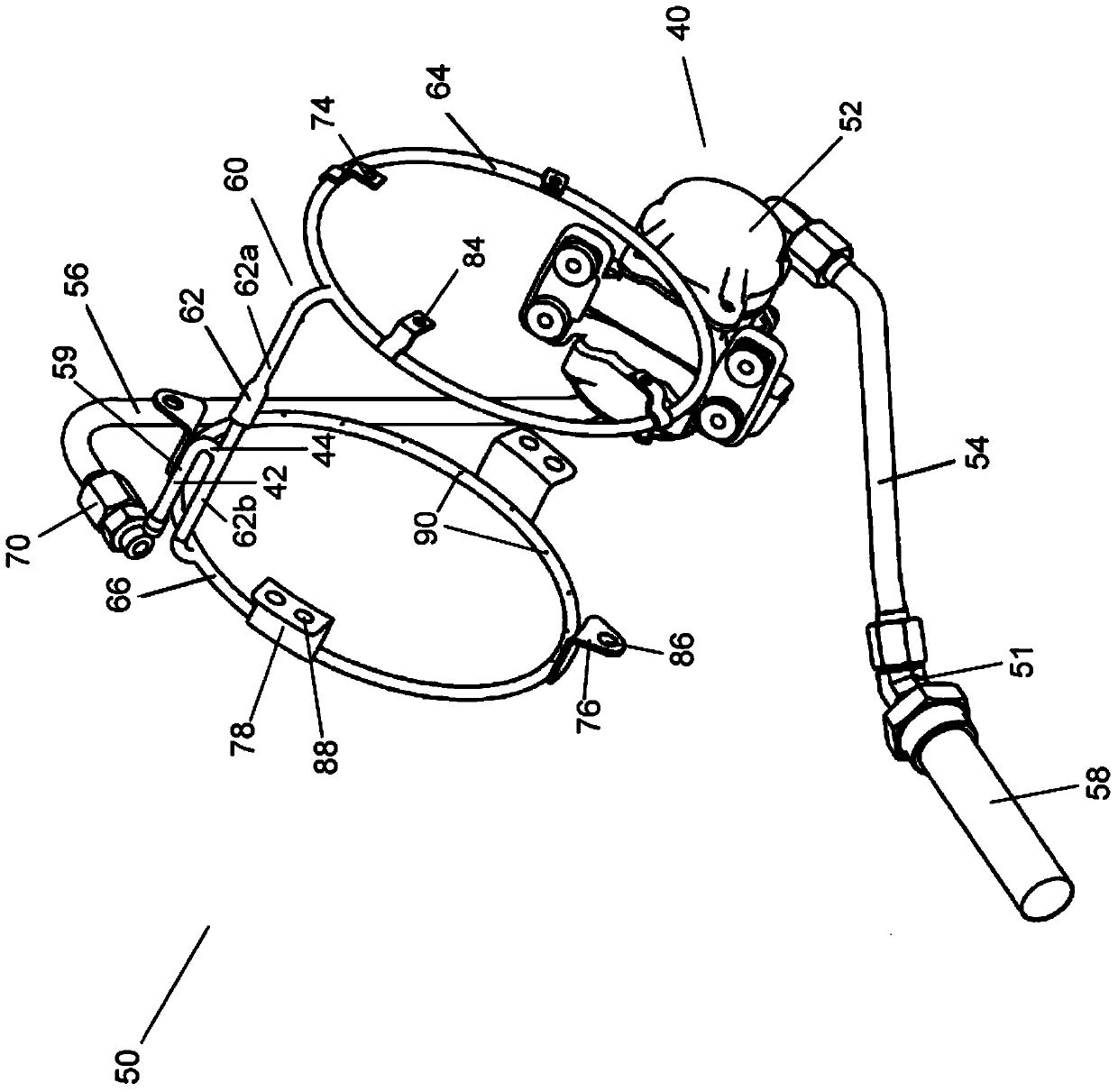

[0024] The motor oil cooling system according to the present invention is mainly used to cool the motor of the electric drive gearbox, and is particularly suitable for, but not limited to, the motor cooling of the electric drive gearbox in hybrid vehicles or other new energy vehicles, and is particularly suitable for The motor is integrated in the electric drive gearbox housing.

[0025] In the present invention, the term "electrically driven gearbox" includes the electrically driven gearbox housing and the components contained in the internal space defined by the electrically driven gearbox housing; the term "electrically driven gearbox housing" refers to The solid material body of the electric drive gearbox housing or the housing wall made of materials; the term "in the electric drive gearbox housing" refers to the internal space defined by the electric drive gearbox housing.

[0026] The following reference is attached Figure 1 to 4 The preferred embodiments of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com