Apparatus and method for manufacturing fine powder by using mixed gas spray

A technology for mixing gas and fine powder, which is applied in the field of raw material powder manufacturing equipment for mixed gas injection, can solve problems such as theoretical difficulties, and achieve the effect of preventing oxidation and omitting the reduction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] best practice

[0053] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. First of all, it should be noted that in assigning reference signs to constituent elements in the respective drawings, the same constituent elements are given the same reference signs as much as possible even if they are displayed in different drawings. In addition, in describing the present invention, when it is judged that the specific description of the relevant known configuration or function is self-evident or likely to confuse the gist of the present invention to those skilled in the art, the detailed description may be omitted.

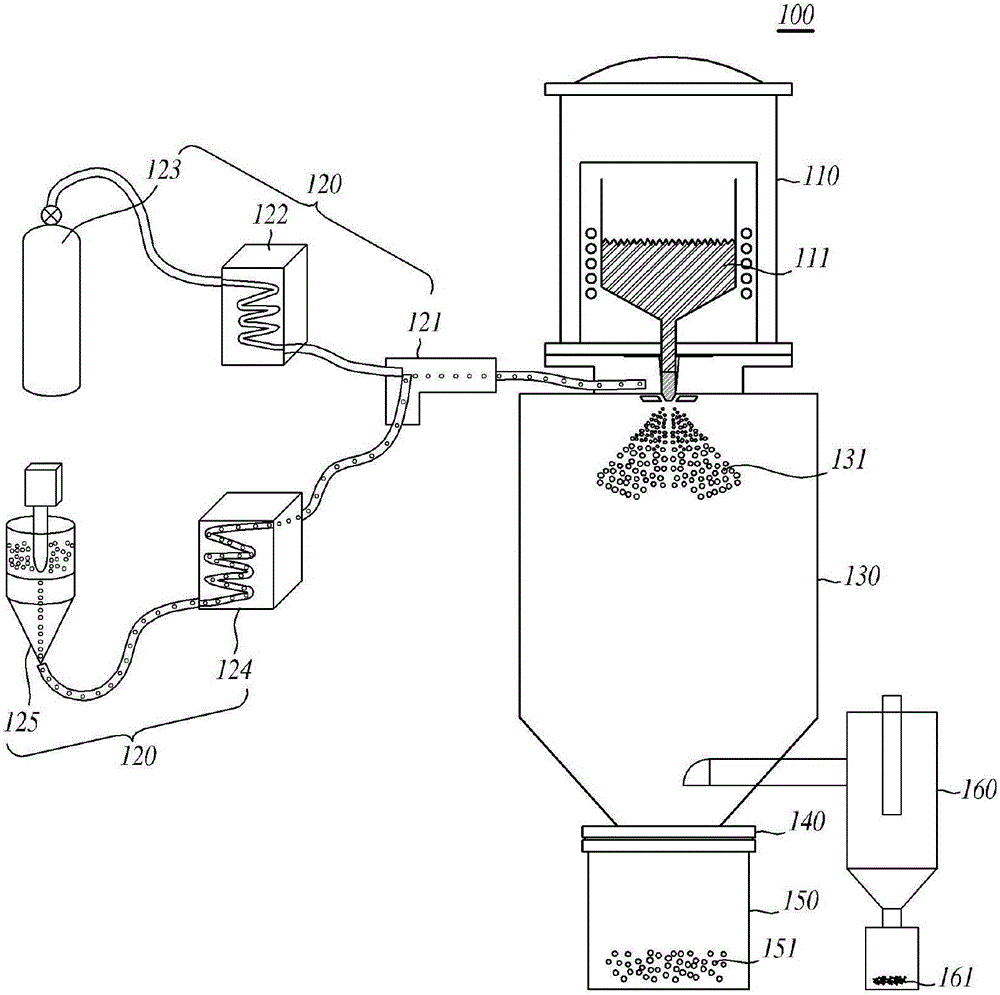

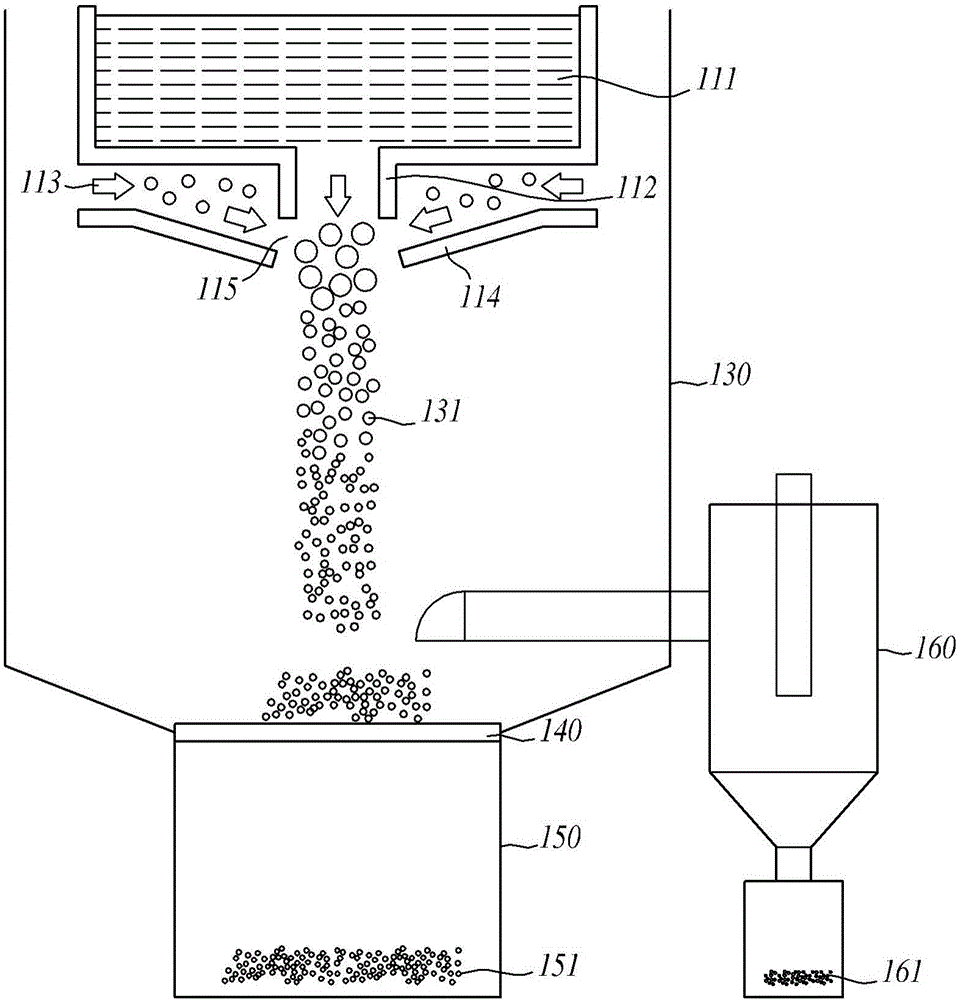

[0054] figure 2 It is a figure which shows the fine powder manufacturing apparatus of one Example of this invention.

[0055] if refer to figure 2 , The fine powder manufacturing device 100 may include a melting chamber 110 , a gas injection device 120 , an accommodating chamber 130 , a gauze 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com