Method for producing a preliminary material for a cutting tool and corresponding preliminary material

A cutting tool, cutting material technology, applied in the direction of manufacturing tools, metal material coating process, other manufacturing equipment/tools, etc., can solve the problem of low processing speed, achieve cost savings, large cost advantages, and improve processing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

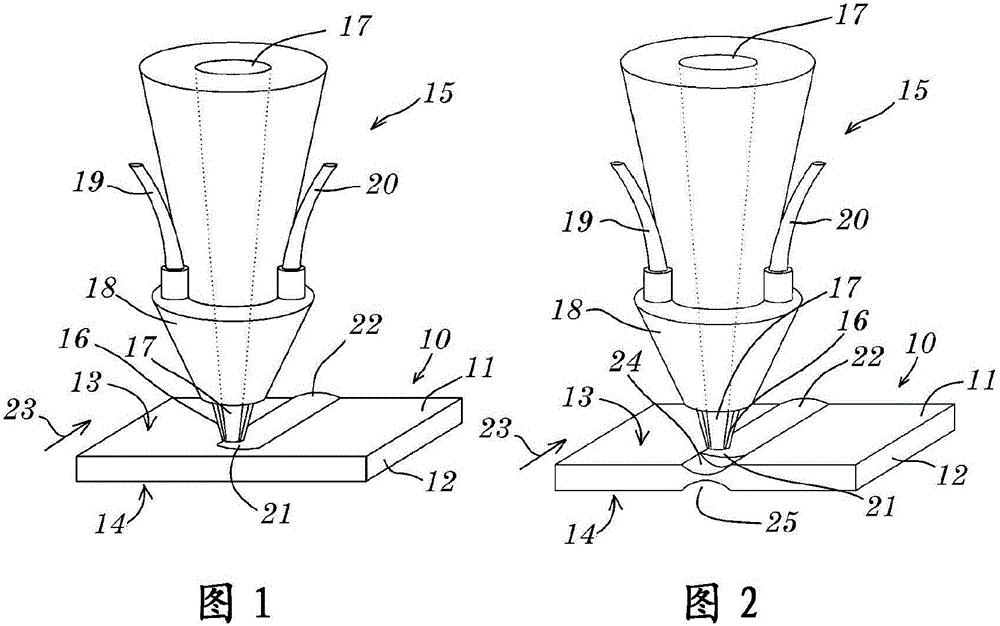

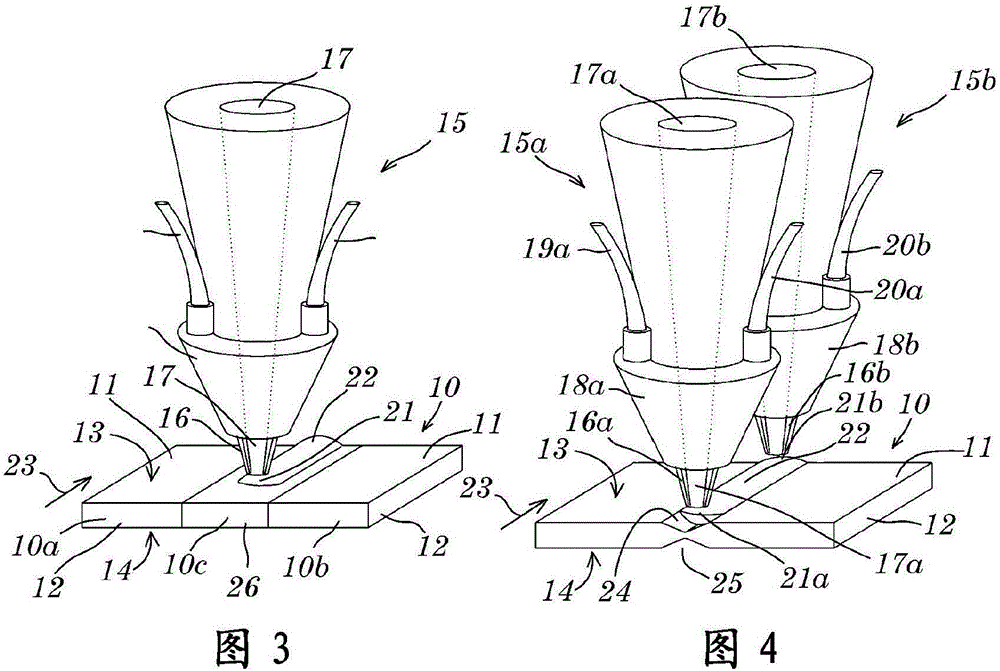

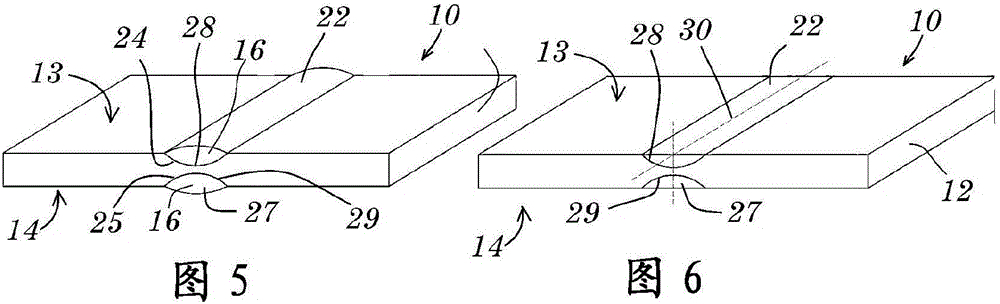

[0055] FIG. 1 shows schematically a first embodiment of the method according to the invention for producing a roughing material for a cutting tool, in particular for producing a saw blade, a saw band or a cutting wire. A flat carrier 10 can be seen, which in the example shown comprises only a uniform base body 11 of carrier material. In the example shown, the flat carrier is shown as a short section for better clarity. However, it is preferably a continuous web which is unwound, for example, from a reel which is not shown here. The flat carrier 10 has a front side 13 and a rear side 14 , which are flat in the example shown. A first particulate cutting material 16 is applied to the front side 13 of the flat carrier 10 by means of a welding head 15 of a welding device (not further shown) and melted by means of a laser beam 17 so that the carrier 10 and the particulate cutting material 16 capable of being welded to each other. In the example shown, the welding head 15 of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com