plasma generator

A plasma and generating device technology, applied in the fields of plasma, semiconductor/solid-state device manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

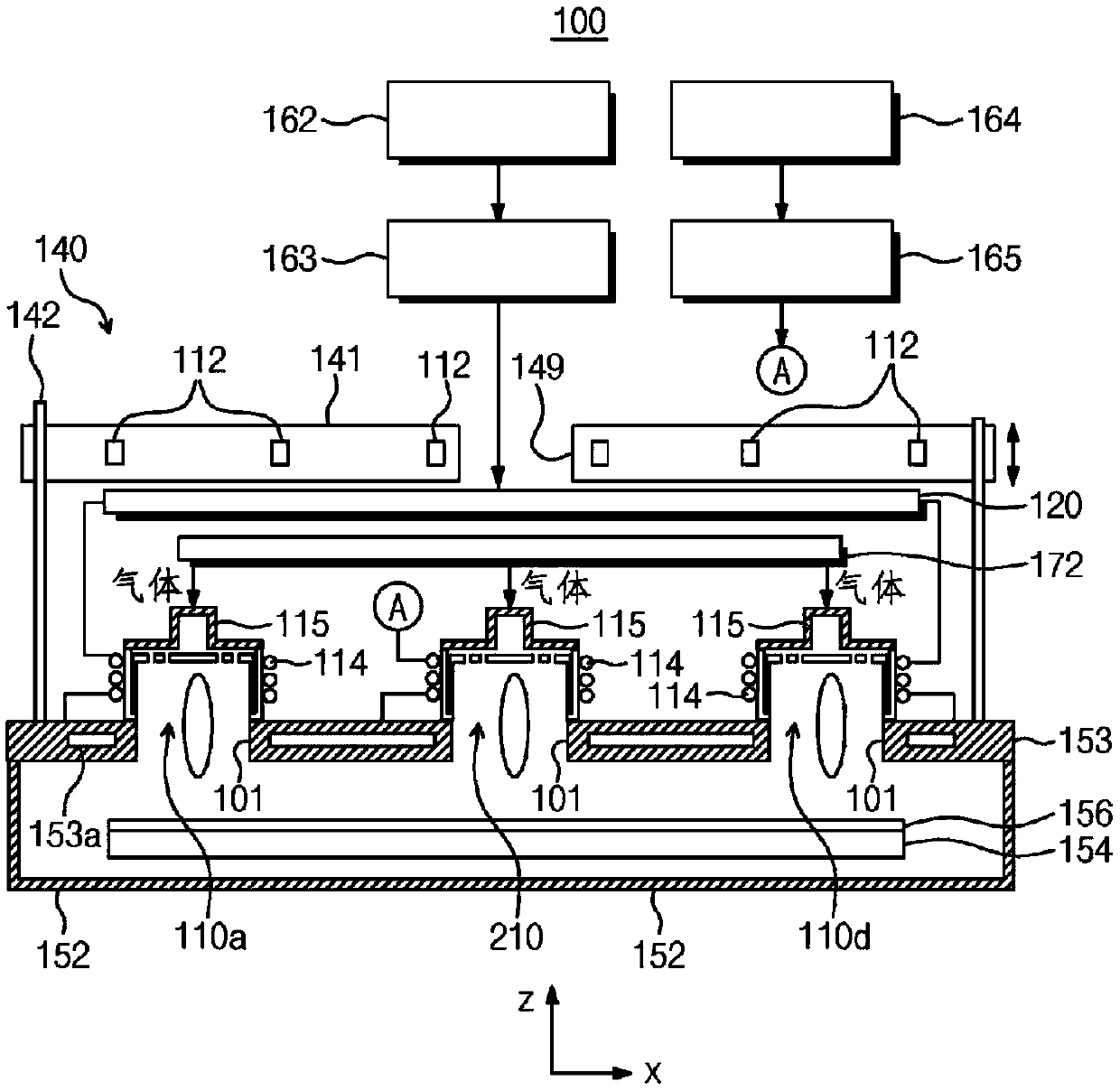

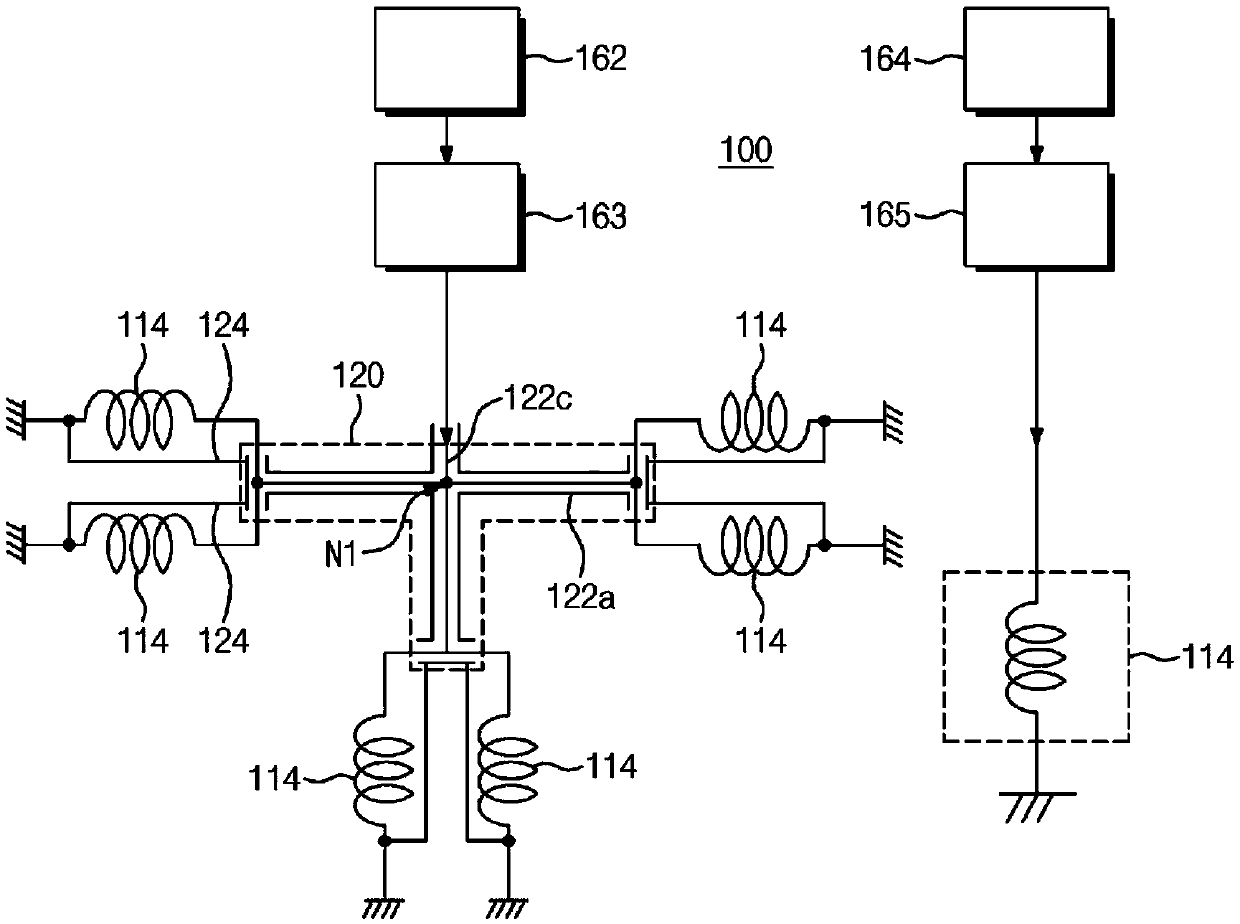

[0030] In the deposition process of silicon oxide layers or silicon oxynitride layers etc. using multiple helicon wave plasma modules, high RF power shows better layer properties. Therefore, when the RF power of each helicon wave plasma module is above 1 kW, the helicon wave plasma modules are severely damaged by heat. A novel structure of the discharge vessel is needed to overcome this problem.

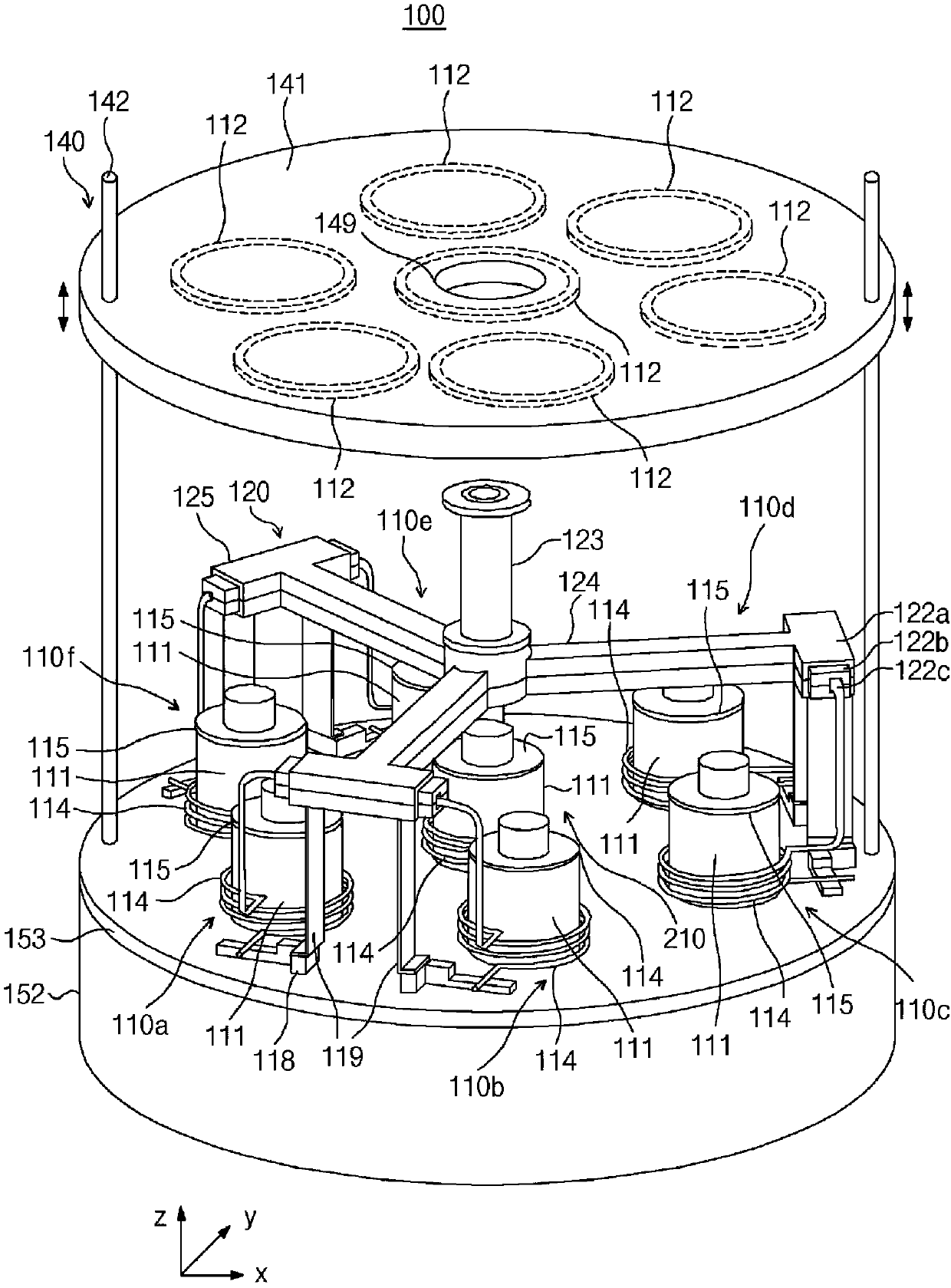

[0031] The helicon wave plasma generating apparatus according to an exemplary embodiment of the present disclosure performs plasma processing in a vacuum vessel at a low pressure of less than several hundred mTorr (mTorr). In addition, the helicon wave plasma generating device generates large-area plasma by combining a plurality of helicon wave plasma modules.

[0032] There is a need for a technique of forming a silicon oxynitride layer by nitrogen diffusion at a temperature below 300°C. High density (10 12 / cm 3 ) plasma generator for nitrogen diffusion. However, conventional in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com