No/low mutton symbiotic solidified goat milk yogurt and preparation method thereof

A technology of coagulation and goat milk, applied in milk preparations, dairy products, applications, etc., can solve problems such as reducing the competitiveness of goat milk and its products, affecting the quality of goat milk yogurt, and affecting the domestic market, so as to promote intestinal tract Digestive system health, improve the body's immunity, and prevent cardiovascular diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Stir the raw milk and goat milk evenly on a magnetic stirrer, pre-mix 7% white sugar and 1% inulin, then slowly add it to the raw milk at room temperature, heat and stir to dissolve it, and add 0.7% polymer at 45°C Whey protein and 0.3% β-cyclodextrin, then heated in goat milk and magnetically stirred for 50 minutes to fully embed the free fatty acids in goat milk, stirred and heated to 85°C, kept for 10 minutes to sterilize, and then quickly cooled in an ice bath When the temperature is lower than 42°C, add 0.006% probiotic starter, stir evenly and ferment at 42°C for 4 hours. After the fermentation is completed, cool the yoghurt to room temperature and store it in a refrigerator at a temperature of 4°C to obtain a finished product.

[0027] The technical index results obtained by product analysis are shown in Table 1 and Table 2

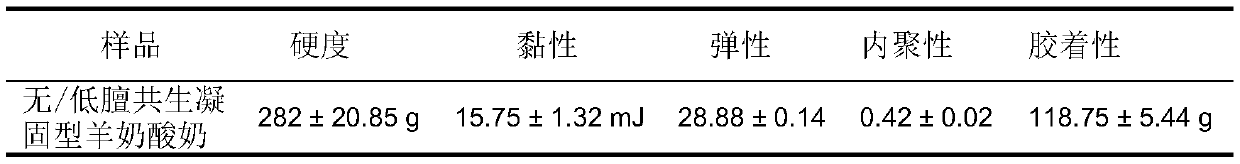

[0028] Table 1 Texture analysis

[0029]

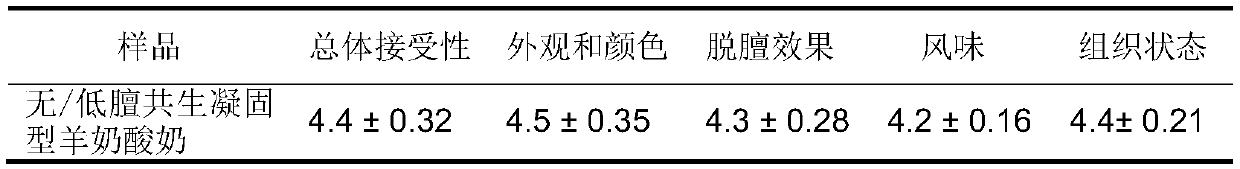

[0030] Table 2 Product Features (5-point scale)

[0031]

[0032] The results of the sen...

Embodiment 2

[0034] Stir the raw milk and goat milk evenly on a magnetic stirrer, pre-mix 8% white sugar, 0.9% inulin, and 0.1% pectin, then slowly add it to the raw milk at room temperature, heat and stir to dissolve it, and then mix 0.6 % polymerized whey protein and 0.4% β-cyclodextrin were added to goat milk at 45°C, heated and magnetically stirred for 45 minutes to fully embed the free fatty acids in goat milk, stirred and heated to 85°C, kept for 10 minutes to sterilize, After cooling in an ice bath to below 42°C, 0.007% probiotic starter was added, stirred evenly and fermented at 42°C for 4.5 hours. After the fermentation was completed, the yogurt was cooled to room temperature and stored in a refrigerator at a temperature of 4°C to obtain finished product.

[0035] The technical index results obtained by product analysis are shown in Table 3 and Table 4.

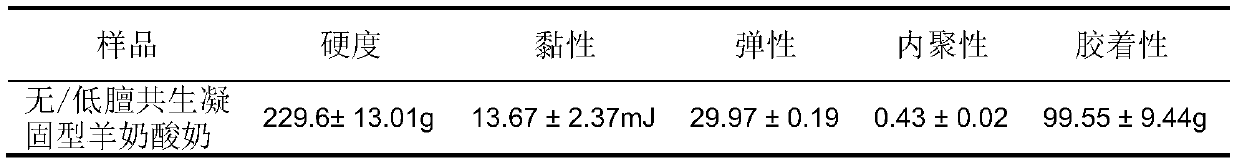

[0036] Table 3 Texture analysis

[0037]

[0038] Table 4 Product Features (5-point scale)

[0039]

[0040]The result...

Embodiment 3

[0042] Stir the raw milk and goat milk evenly on a magnetic stirrer, pre-mix 6% white sugar, 1.5% inulin, and 0.2% pectin, then slowly add it to the raw milk at room temperature, heat and stir to dissolve it, and then mix 0.8 % polymerized whey protein and 0.1% β-cyclodextrin were added to goat milk at 45°C, heated and magnetically stirred for 30 minutes to fully embed the free fatty acids in goat milk, stirred and heated to 80°C, kept for 10 minutes to sterilize, After that, quickly cool in an ice bath to below 42°C, add 0.01% probiotic starter, stir evenly and ferment at 42°C for 4 hours. After the fermentation is completed, cool the yogurt to room temperature and store it in a refrigerator at a temperature of 4°C to obtain the finished product .

[0043] The technical index results obtained by product analysis are shown in Table 5 and Table 6.

[0044] Table 5 texture analysis

[0045]

[0046] Table 6 Product Features (5-point scale)

[0047]

[0048] The results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com