A method for preparing fullerene nanostructures

A nanostructure and fullerene technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult realization, complicated process, high cost, etc., and achieve the effect of good structural state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

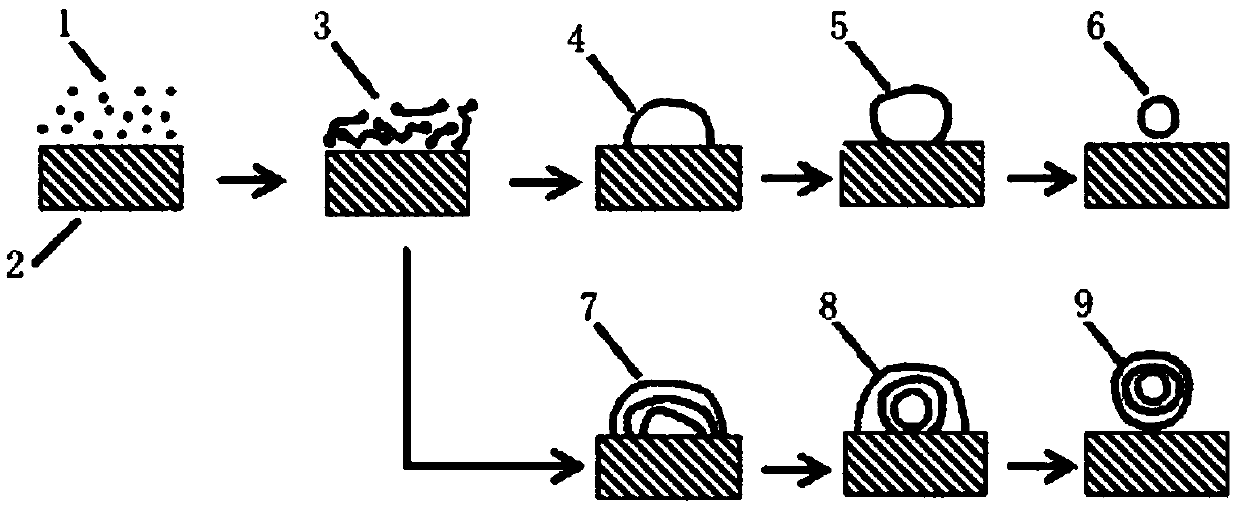

Method used

Image

Examples

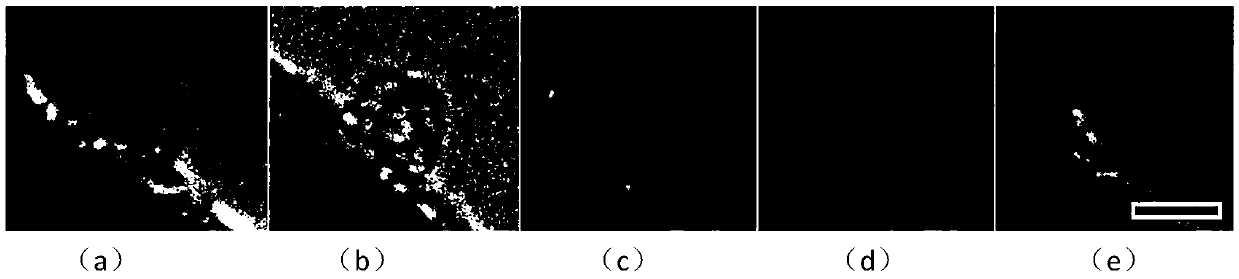

Embodiment 1

[0023] Implementation example 1: at room temperature, the substrate is made of zinc oxide. The thickness of the amorphous carbon film is about 2 nm. The sample is placed in a vacuum chamber with a vacuum degree of about 1.0×10^(-4)Pa, and the electron beam is turned on to irradiate the designated position. The electron beam intensity is about 1*10 3 e*s^(-1)*nm^(-2). Use a transmission electron microscope to observe the surface condition of the sample at intervals of 2-10 minutes. The result obtained is shown in the figure figure 2 shown. After about 50 minutes of electron beam irradiation, it can be seen that a single monolayer fullerene structure is finally formed at the designated position on the ZnO surface.

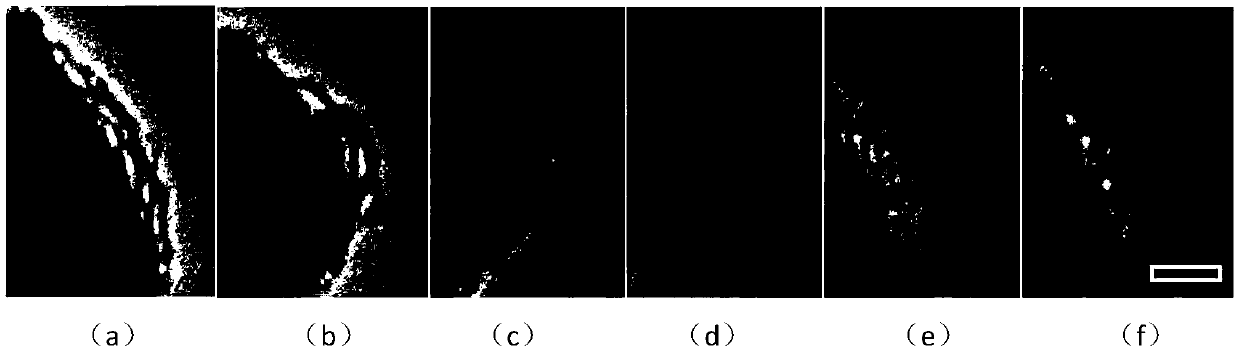

Embodiment 2

[0024] Implementation example 2: at room temperature, the substrate is made of zinc oxide. The thickness of the amorphous carbon film is about 3.5 nm. The sample is placed in a vacuum chamber with a vacuum degree of about 5.0×10^(-5)Pa, and the electron beam is turned on to irradiate the designated position. Electron beam intensity 1*10 5 e*s^(-1)*nm^(-2). Use a transmission electron microscope to observe the surface condition of the sample at intervals of 2-10 minutes. The result obtained is shown in the figure image 3 shown. After about 70 minutes of electron beam irradiation, it can be seen that a single double-layer fullerene structure is finally formed at the designated position on the ZnO surface.

Embodiment 3

[0025] Implementation example 3: at room temperature, the substrate is made of zinc oxide. The thickness of the amorphous carbon film is about 6 nm. The sample is placed in a vacuum chamber with a vacuum degree of about 1.0×10^(-5)Pa, and the electron beam is turned on to irradiate the designated position. Electron beam intensity 1*10 5 e*s^(-1)*nm^(-2). Use a transmission electron microscope to observe the surface condition of the sample at intervals of 2-10 minutes. The result obtained is shown in the figure Figure 4 shown. After about 100 minutes of electron beam irradiation, it can be seen that a single three-layer fullerene structure is finally formed at the designated position on the ZnO surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com