A high-plastic heat-resistant AZ series high-aluminum-magnesium alloy extrusion material and its preparation method

A technology for magnesium alloys and extruded materials, which is applied in the field of preparation of high-plastic heat-resistant AZ high-aluminum magnesium alloys and their extruded materials, can solve the problems of low elongation at room temperature, achieve improved elongation at room temperature, and improve Grain boundary structure state, extrusion process is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the extruded high plastic and heat-resistant AZ series high-aluminum-magnesium alloy consists of the following components in mass percentage: 9.0% Al, 0.7% Zn, 0.2% Mn, 0.4% Sm+0.05% La, and the balance is magnesium and unavoidable impurity elements.

[0028] Its preparation method is as follows:

[0029] Using a resistance melting furnace, in SF 6 with CO 2 Under the protective atmosphere of a mixed gas with a volume ratio of 1:100, heat Mg to 710°C to melt, add Al, Zn and Mn according to the mass percentage of the components, and use RJ-5 flux to purify and cover the magnesium alloy melt , according to the mass percentage of Sm and La, add Mg-30%Sm and Mg-25%La master alloy, heat up to 730°C, continue to add RJ-5 flux for refining and stirring after the alloy is melted, then let it stand for 9min, until the melt temperature When the temperature is lowered to 710°C, the slag is removed, and cast into a low-carbon steel mold preheated to 200°C und...

Embodiment 2

[0032] In this embodiment, the extruded high plastic and heat-resistant AZ series high-aluminum-magnesium alloy consists of the following components in mass percentage: 9.43% Al, 0.5% Zn, 0.1% Mn, 0.15% Sm+0.3% La, and the balance is magnesium and unavoidable impurity elements.

[0033] Its preparation method is identical with embodiment 1.

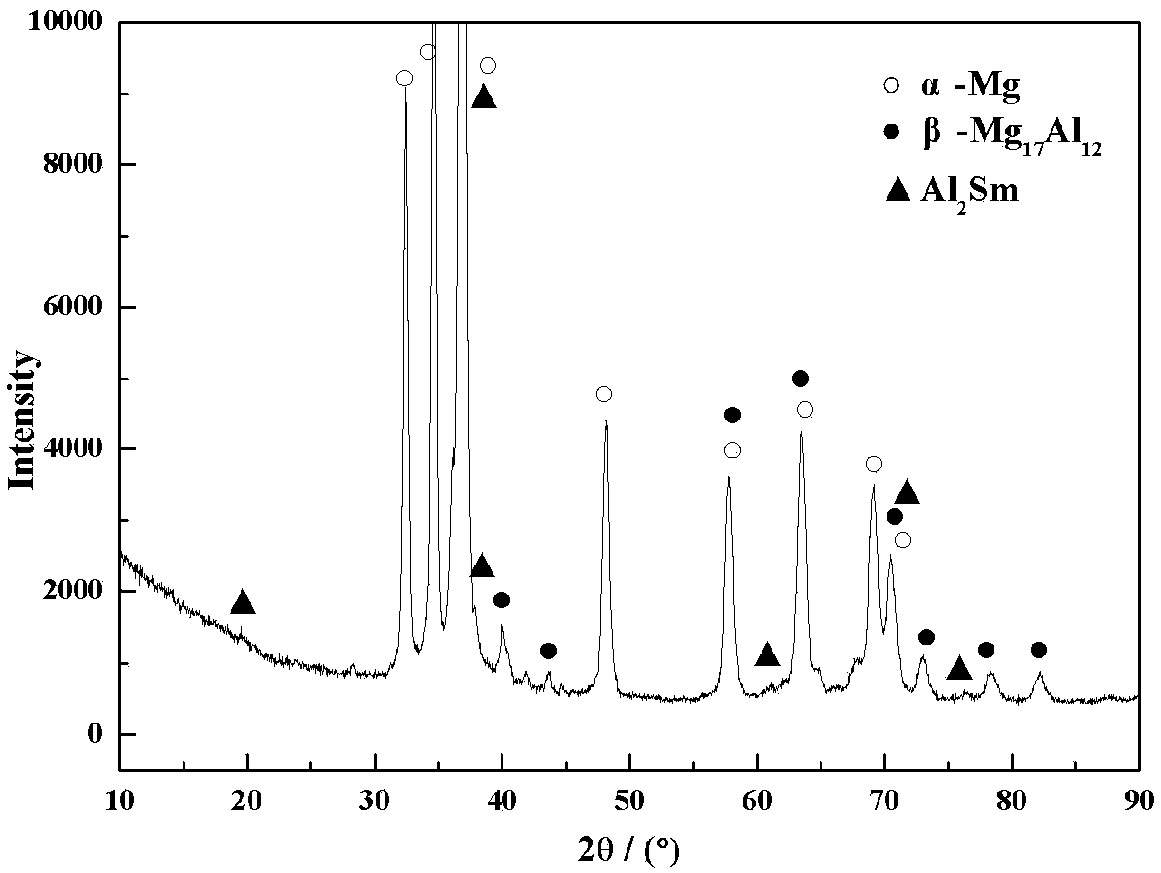

[0034] The XRD spectrum of the extruded material is attached Figure 5 As shown, the typical metallographic structure is as attached Figure 6 As shown, the SEM tissues are as attached Figure 7 shown. process it into Figure 4 The tensile samples shown were stretched at room temperature and 150°C on an Instron8032 stretching machine, and the stretching speed was 1mm / min. The tensile properties were shown in Table 1, and the average values were: at room temperature, Tensile strength=330MPa, yield strength=180MPa, elongation=26%, yield strength ratio is 0.545; at high temperature (150°C), tensile strength=270MPa, yield strength=177M...

Embodiment 3

[0036] In this embodiment, the extruded high plastic and heat-resistant AZ series high-aluminum-magnesium alloy consists of the following components in mass percentage: 10.5% Al, 0.5% Zn, 0.12% Mn, 0.2% Sm+0.15% La, and the balance is magnesium and unavoidable impurity elements.

[0037] Its preparation method is identical with embodiment 1.

[0038] process it into Figure 4 The tensile samples shown were stretched at room temperature and 150°C on an Instron8032 stretching machine, and the stretching speed was 1mm / min. The tensile properties were shown in Table 1, and the average values were: at room temperature, Tensile strength=333MPa, yield strength=182MPa, elongation=23%, yield strength ratio is 0.550; at high temperature (150°C), tensile strength=260MPa, yield strength=173MPa, elongation=33%, yield strength The ratio is 0.665.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com