Peanut kernel dry protein prepared from soy isolate protein and vital gluten and method for preparing peanut kernel dry protein from soy isolate protein and vital gluten

A protein powder and gluten technology, applied in the field of food processing, can solve the problems of inability to carry out industrialized production, the finished dried bean curd is not high in nutrition, and the production process is complicated and complicated, so as to reduce the pungency, improve the health care effect, and simplify the traditional process. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

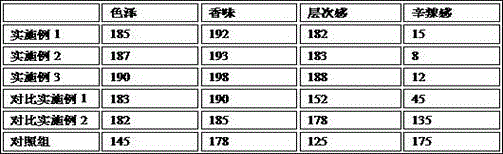

Examples

Embodiment 1

[0031] The dried peanut kernel protein prepared by soybean protein isolate powder and gluten powder comprises the following raw materials in parts by weight: 80 parts of soybean protein isolate powder, 140 parts of gluten powder, 20 parts of peanut kernels, 20 parts of honey, and 1 part of star anise , 12 parts of dried chili, 1 part of mint, 12 parts of table salt, 1 part of grass fruit, 4 parts of tangerine peel, 1 part of amomum, 10 parts of dove tree fruit and 1 part of Angelica dahurica.

[0032] The preparation method of described dried peanut kernel protein is as follows:

[0033] (1) Raw material pretreatment: mix and grind dried chili, mint, grass fruit, tangerine peel, amomum, angelica dahurica and star anise into a mixed powder;

[0034] (2) Preparation of seasoning: add honey and crushed Davidia involucrata fruit to the mixed powder, and stir evenly to obtain the seasoning;

[0035] (3) Frying: put the peanut kernels into the pot, stir-fry with a slow fire for 10 ...

Embodiment 2

[0041] The dried peanut kernel protein prepared by soybean protein isolate powder and gluten powder comprises the following raw materials in parts by weight: 120 parts of soybean protein isolate powder, 80 parts of gluten powder, 60 parts of peanut kernels, 12 parts of honey, and 5 parts of star anise , 2 parts of dried chili, 5 parts of mint, 2 parts of table salt, 6 parts of Cao Guo, 1 part of tangerine peel, 7 parts of amomum, 4 parts of dove tree fruit and 6 parts of Angelica dahurica.

[0042] The preparation method of described dried peanut kernel protein is as follows:

[0043] (1) Raw material pretreatment: mix and grind dried chili, mint, grass fruit, tangerine peel, amomum, angelica dahurica and star anise into a mixed powder;

[0044] (2) Preparation of seasoning: add honey and crushed Davidia involucrata fruit to the mixed powder, and stir evenly to obtain the seasoning;

[0045] (3) Frying: Put the peanut kernels into the pot, stir-fry with a slow fire for 15 minut...

Embodiment 3

[0051] The dried peanut kernel protein prepared by soybean protein isolate powder and gluten powder comprises the following raw materials in parts by weight: 110 parts of soybean protein isolate powder, 100 parts of gluten powder, 70 parts of peanut kernels, 6 parts of honey, and 3 parts of star anise , 7 parts of dried chili, 2 parts of mint, 6 parts of table salt, 3 parts of Cao Guo, 2 parts of tangerine peel, 3 parts of amomum, 2 parts of dove tree fruit and 3 parts of Angelica dahurica.

[0052] The preparation method of described dried peanut kernel protein is as follows:

[0053] (1) Raw material pretreatment: mix and grind dried chili, mint, grass fruit, tangerine peel, amomum, angelica dahurica and star anise into a mixed powder;

[0054] (2) Preparation of seasoning: add honey and crushed Davidia involucrata fruit to the mixed powder, and stir evenly to obtain the seasoning;

[0055] (3) Frying: put the peanut kernels into the pot, stir-fry with a slow fire for 12 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com