Processing equipment for stirring and processing paint

A technology for processing equipment and coatings, which is applied to mixers with rotating stirring devices, mixer accessories, dissolution, etc., can solve the problems of popularization and application troughs, and achieve the effects of reasonable use, improved connection strength, and scientific structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

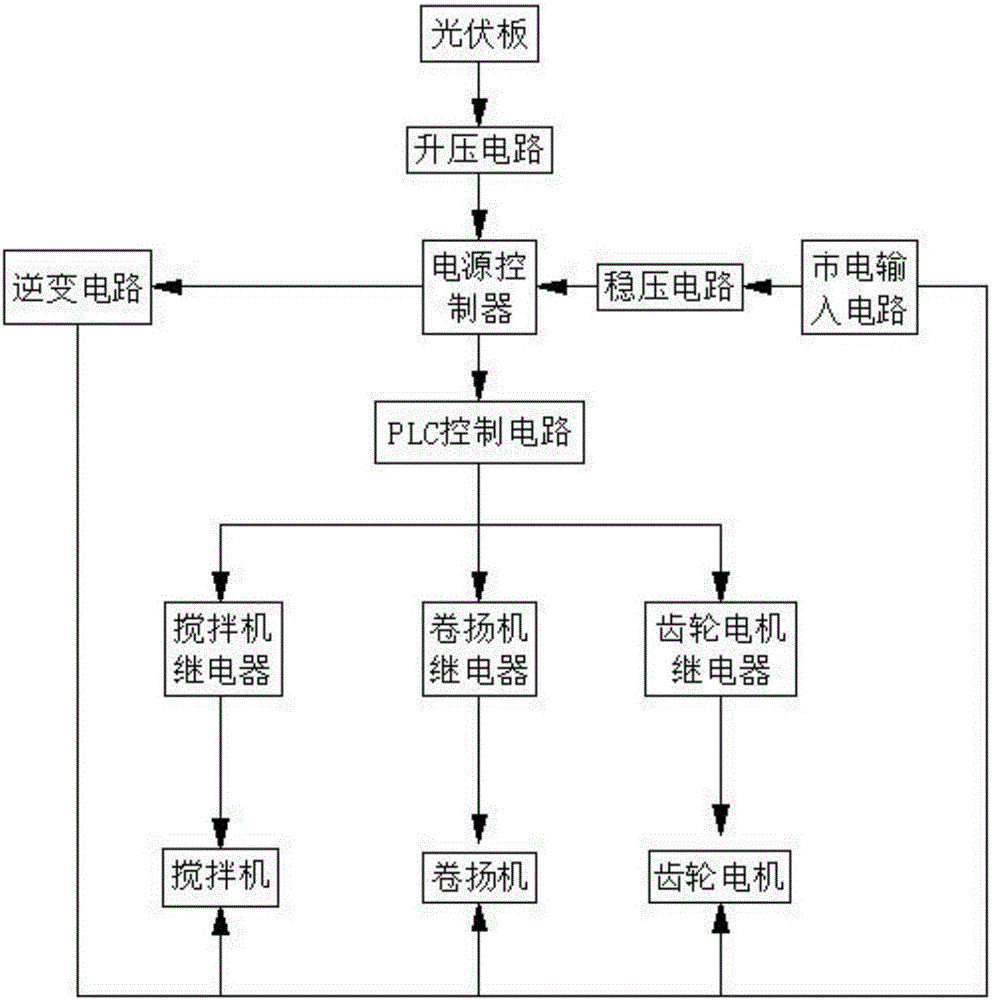

[0041] A kind of processing equipment for paint mixing processing, when the paint is stirring processing, it uses solar energy to supply power, so as to achieve the purpose of energy saving and environmental protection, and adopts the power supply mode of the combination of mains power and solar power to provide power so that the entire processing equipment can Long-term stable power supply to avoid production failure due to power outages; during power supply, solar power is effectively used for DC power supply, so that the control circuit in the processing equipment can be directly powered by solar power instead of relying entirely on the market. Electric power supply, so as to achieve the purpose of scientific production, such as figure 1 , figure 2 As shown, the following configuration structure is particularly adopted: including the processing equipment body and the power supply system for supplying power to the processing equipment body, the power supply system is equipp...

Embodiment 2

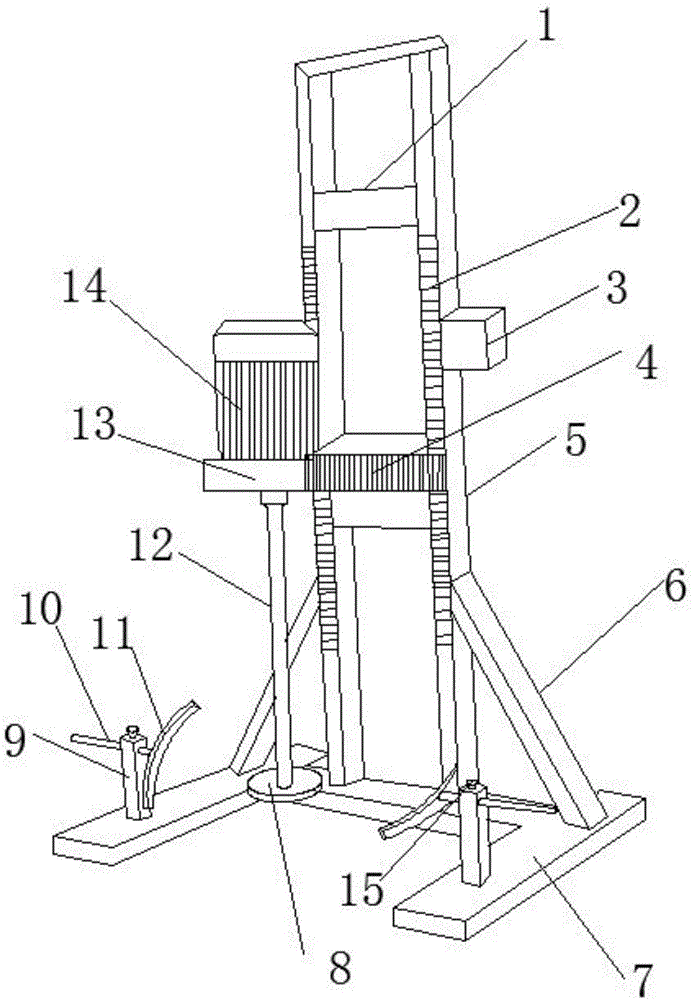

[0044] This embodiment is further optimized on the basis of the above embodiments. In order to further realize the present invention better, the main frame of the gantry with a door frame structure is used to carry out the load-bearing fixing of the mixing mechanism, and combined with the platform for supporting the main frame of the gantry The structural design is used to fix the paint mixing barrel fixing mechanism of the mixing barrel. The paint mixing barrel fixing mechanism designed in a detachable combination can flexibly and conveniently fix the mixing barrel of the main body size for paint mixing processing, and adopts a rack The mechanism cooperates with the design structure of the stirring mechanism to move the stirring mechanism on the main frame of the gantry, so that the physical expenditure of the operator can be effectively saved during processing, making production and processing more convenient, and overcoming the problem of poor stirring quality during manual s...

Embodiment 3

[0047] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 , figure 2 As shown, the following arrangement structure is adopted in particular: the hoisting power device includes a hoist relay and a hoist, the PLC control circuit is connected to the hoist relay, the hoist relay is connected to the hoist, the inverter circuit and the mains input circuit are all connected to the hoist; The rack power device includes a gear motor relay and a gear motor, the PLC control circuit is connected to the gear motor relay, the gear motor relay is connected to the gear motor, the inverter circuit and the mains input circuit are connected to the gear motor; the inverter is controlled by the winch relay The power on the variable circuit or the power on the mains input circuit loads the hoist, so that the hoist works, and then the hoist drives the mixing bucket to be removed or put into the paint m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com