Manufacturing device for chopped peppers

A preparation device and technology for chopping peppers, which can be used in solid separation, sieving, grilling, etc., can solve the problem that pepper shears cannot provide uniform quality chopped peppers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

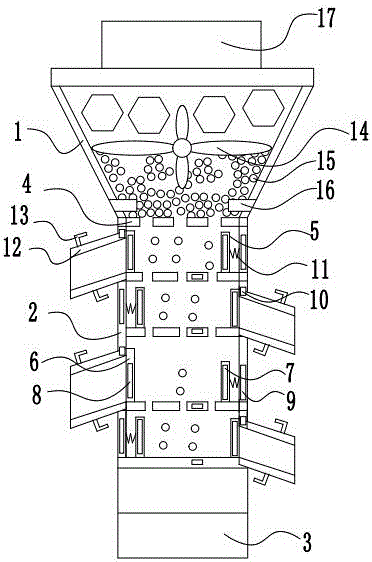

[0027] The reference signs of the drawings in the description include: hopper 1, chopped pepper cylinder 2, vibration motor 3, sieve plate 4, pressing plate 5, baffle plate 6, first magnet piece 7, second magnet piece 8, first electromagnet 9, Second electromagnet 10, spring 11, output pipe 12, hook 13, agitator 14, chopped pepper 15, hair dryer 16, collection bag 17.

[0028] Such as figure 1 As shown, the preparation device for chopped peppers includes a hopper 1 connected by bolts, a chopped pepper tube 2 and a vibration motor 3 for driving the hopper 1 and the chopped pepper tube 2 to vibrate from top to bottom. A top plate with a through hole is installed at the junction of the chopped pepper tube 2 and the hopper 1, and a non-perforated bottom plate is installed at the junction of the chopped pepper tube 2 and the vibrating motor 3 . There are three sieve plates 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com