Lamination stringer

A welding machine and lamination technology, applied in welding equipment, manufacturing tools, metal processing and other directions, can solve the problems of low production efficiency, unable to meet mass production, and the welding machine cannot be suitable for production processes, etc., and achieve high production efficiency. , to meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below according to the drawings and embodiments.

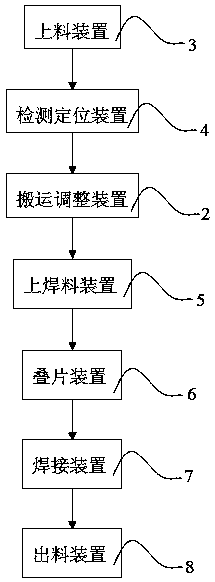

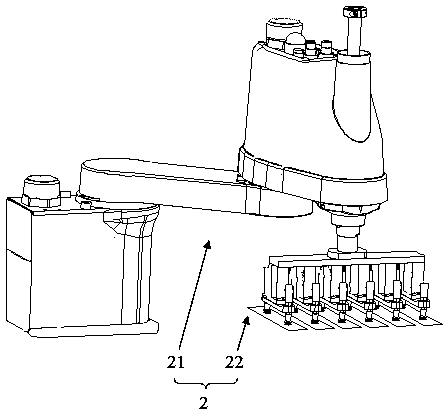

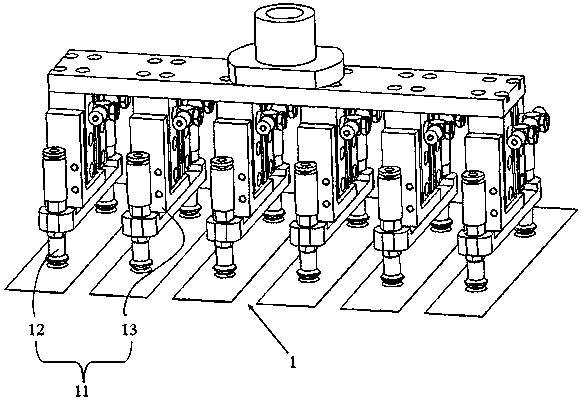

[0026] Such as figure 1 As shown, the lamination stringer according to the embodiment of the present invention includes a feeding device 3, a detection and positioning device 4, a handling adjustment device 2, a soldering device 5, a lamination device 6, and a welding device arranged along the conveying line. 7; The upper soldering device 5 is used to apply conductive glue and / or solder paste on the upper solder position of the battery sheet; the stacking device 6 is used to stack the battery sheets processed by the upper soldering device 5, and the adjacent battery sheets The overlapping area covers the upper solder position; the welding device 7 heats and welds the conductive glue and / or solder paste on the upper solder position of the battery sheet to form a battery string; the discharge device 8 is used for discharging and conveying the battery string.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com