Modular robot teaching system

A teaching system and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of no external interface, low controllability, and poor practicability, so as to enhance operability and human-computer interaction , easy to disassemble and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

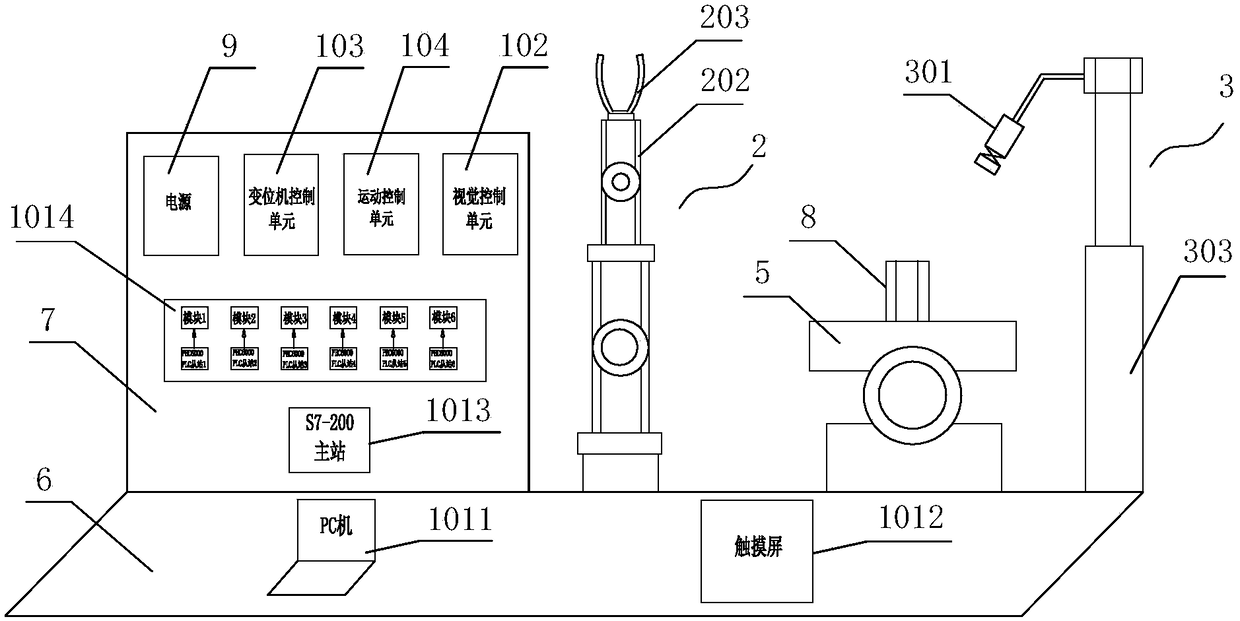

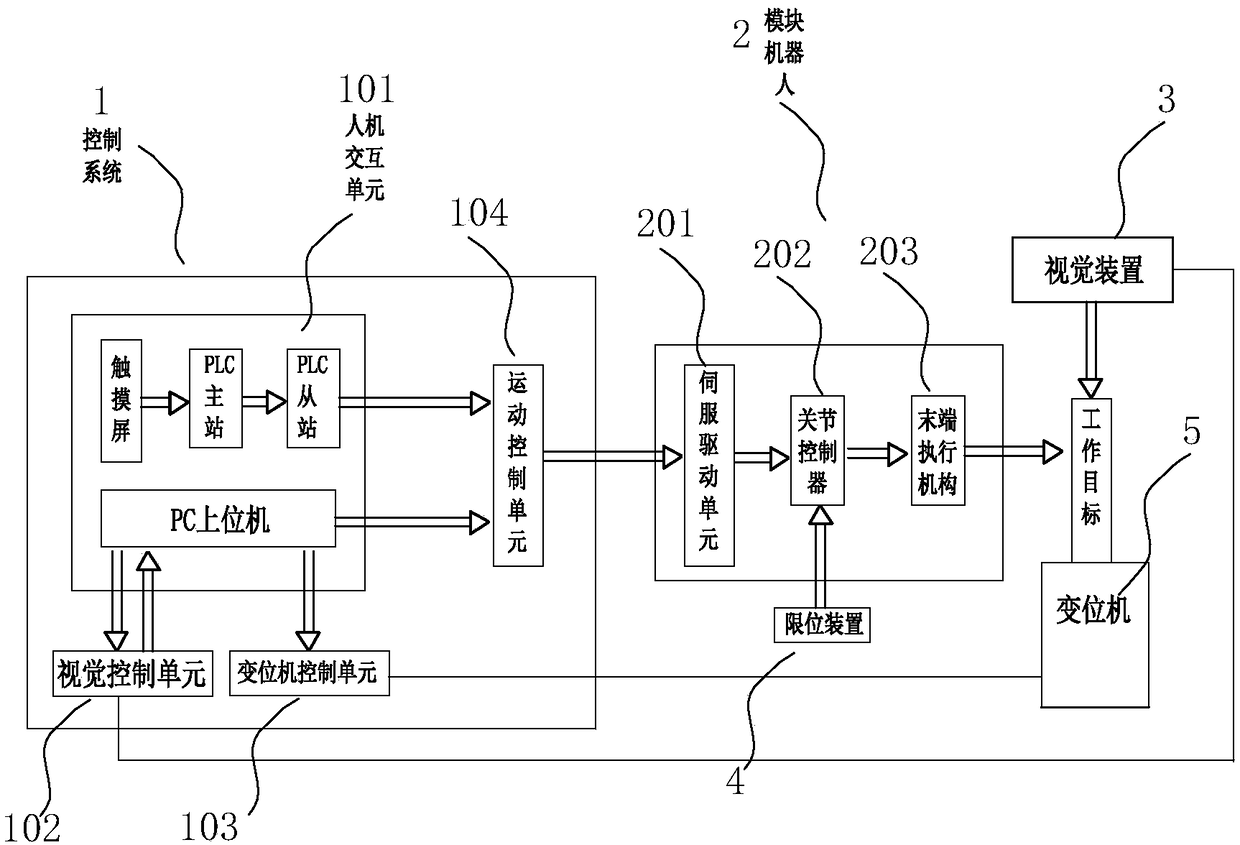

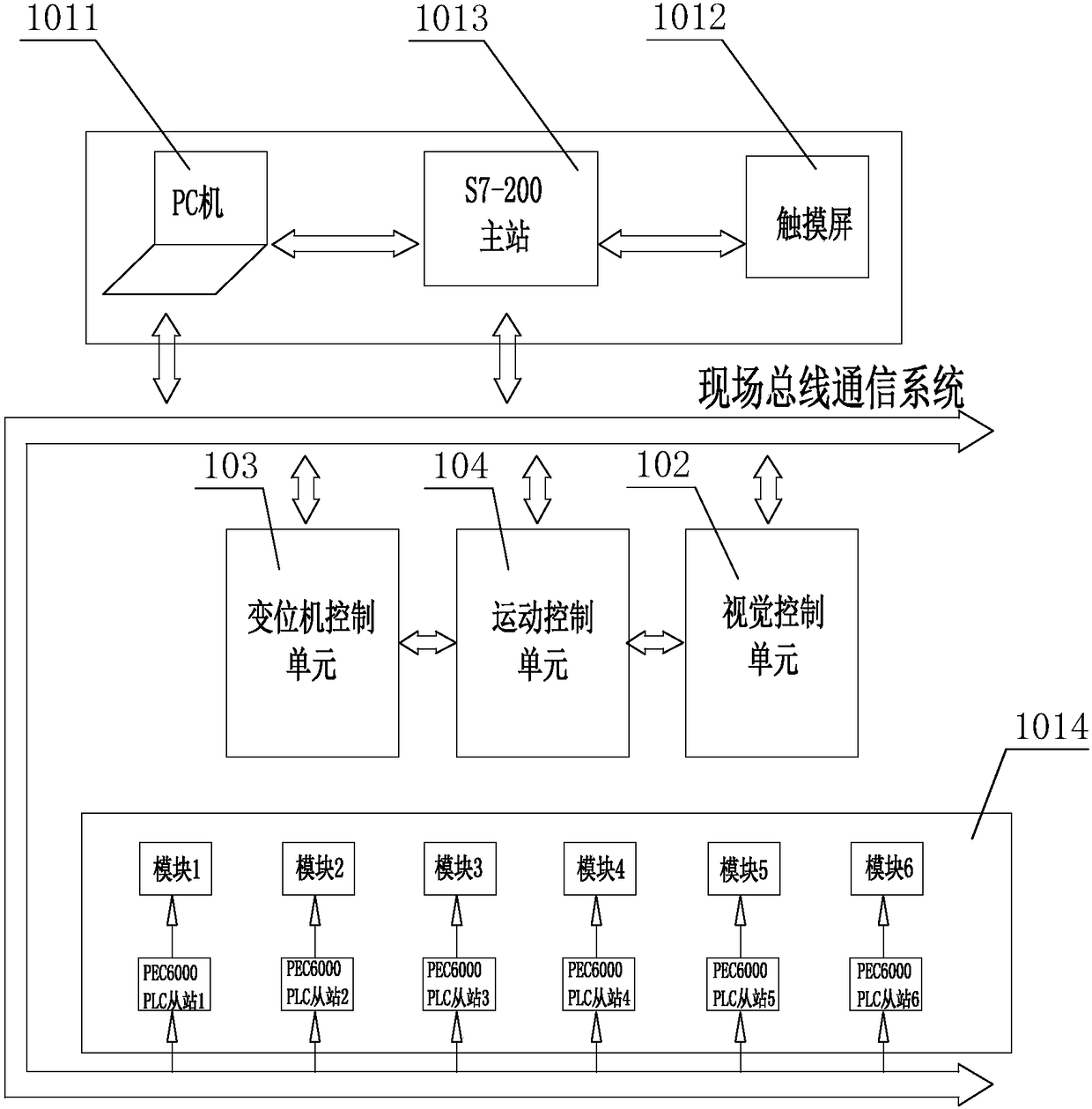

[0053] A modular robot teaching system, including a workbench, a work target installed on the workbench, a modular robot, a control system and a communication system;

[0054] The modular robot exchanges information with the control system through the communication system and is controlled by the control system. The working target is installed on the workbench through the positioner, and a visual device for monitoring the working target is provided on one side of the positioner. The visual device The positioner is connected with the control system through the communication system and controlled by the control system, and the positioner is connected with the control system through the communication system and controlled by the control system;

[0055] The modular robot is a serial modular robot, that is, the N modules that constitute the modular robot are connected in series through joints, and the mechanical installation interfaces between the joints of the modules are the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com