A grabbing method with claw structure for automatic grabbing of engine casing

A technology for engine housings and grippers, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as easy deformation, high cost, and large volume, and achieve the goals of ensuring positioning accuracy, improving adaptability, and increasing gripping force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

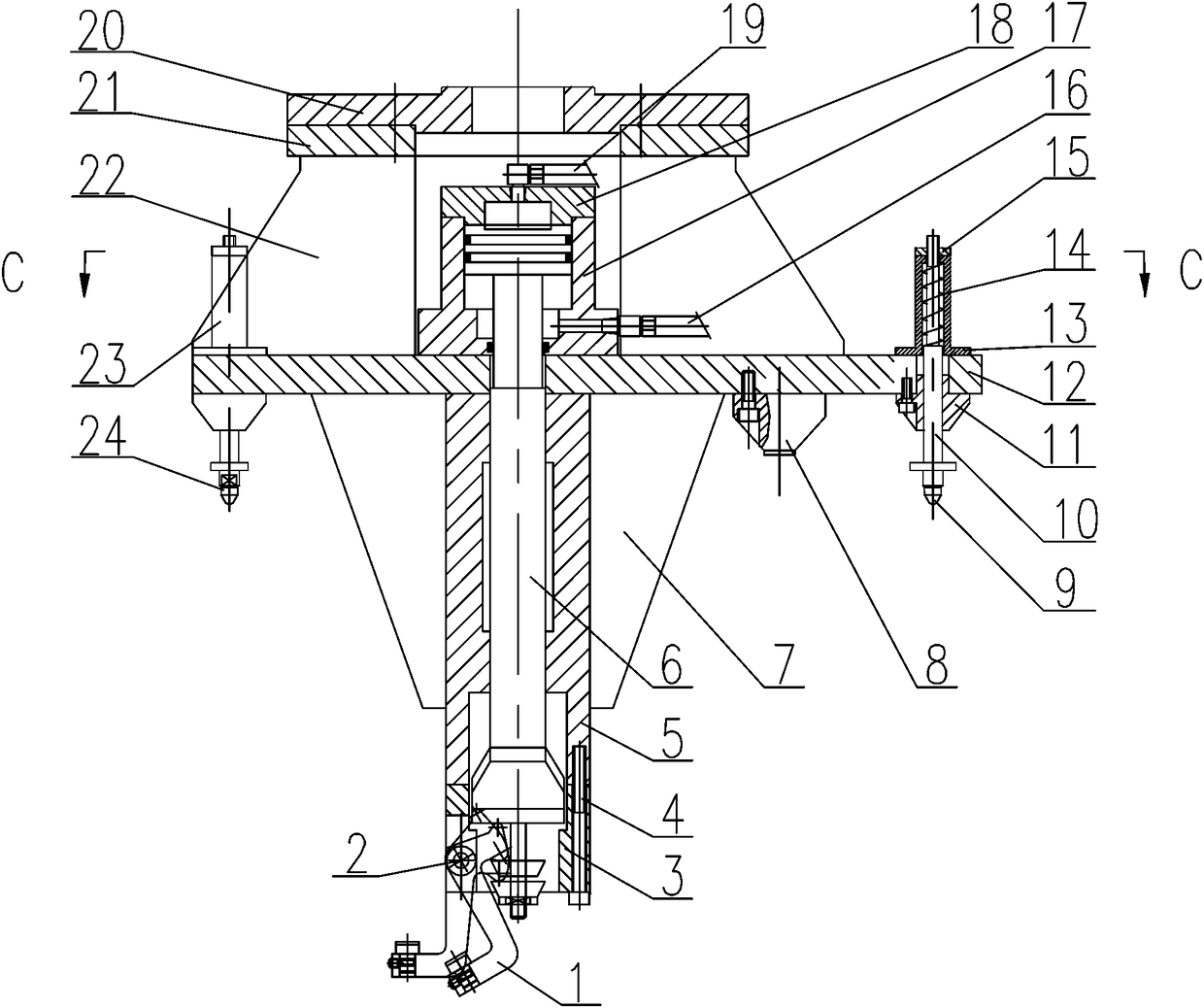

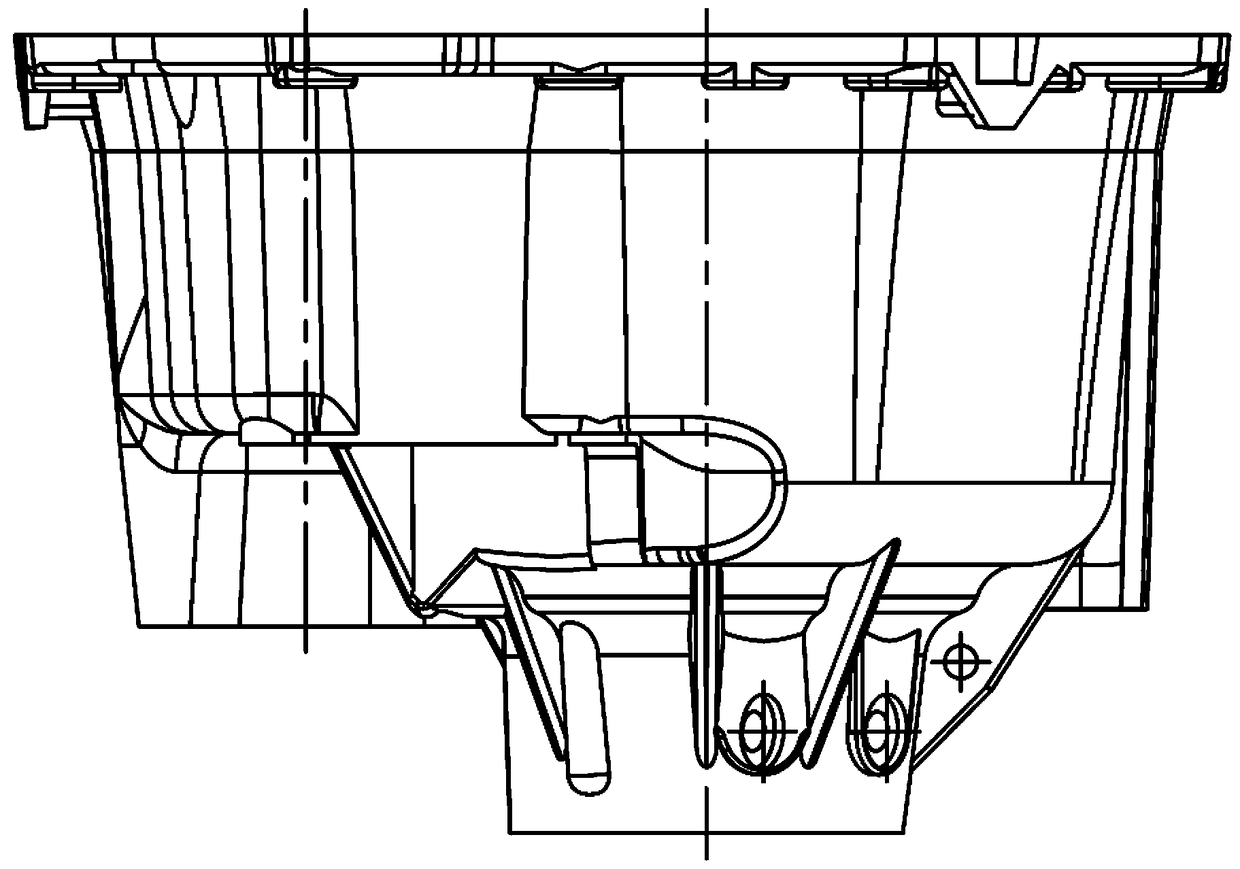

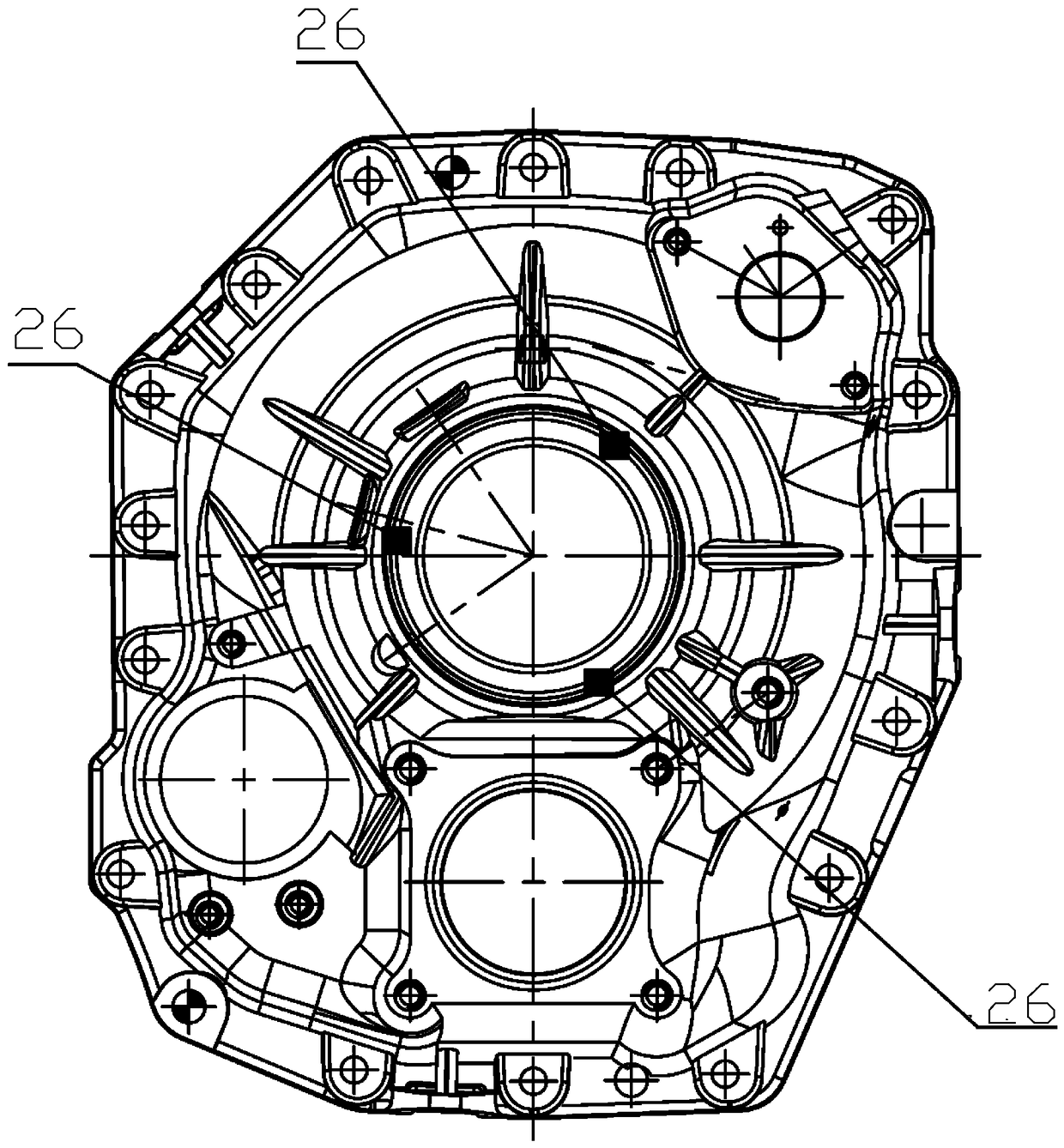

[0048] Such as Figure 1-9, a claw structure for automatic grabbing of the engine casing, which includes a plurality of claw heads 1, the claw heads 1 are hinged on the head of the claw head seat 3 through a pin shaft 2, and the claw head seat 3 is fixedly installed on The end of the sliding sleeve 5, the sliding sleeve 5 is fixed on the lower end surface of the bottom plate 12, the sliding sleeve 5 is fitted with a piston rod 6, and the bottom end of the piston rod 6 cooperates with the claw head 1 to control the claw head 1, the top of the piston rod 6 is matched with the oil cylinder seat 17, and the oil cylinder seat 17 is fixed on the upper surface of the bottom plate 12, and the bottom end of the oil cylinder seat 17 is processed with a No. 1 oil inlet 16. An oil cylinder cover 18 is installed on the top of the oil cylinder block 17, and the top of the oil cylinder cover 18 is processed with a No. 2 oil inlet 19. The top of the bottom plate 12 is equipped with a top plat...

Embodiment 2

[0060] Using any claw structure to grab the engine housing method, it includes the following steps:

[0061] S1: Fix the claw structure on the head of the mechanical arm through the flange 20, and connect the No. 1 oil inlet 16 and the No. 2 oil inlet 19 to the hydraulic system respectively;

[0062] S2: At the beginning, the claw head 1 is in the folded state, and the mechanical arm drives the gripping structure to insert the sliding sleeve 5 of the claw head 1 into the center hole of the engine housing, so as to ensure that the round pin head 9 and the diamond pin 24 on the bottom surface of the bottom plate 12 are in line with the The two positioning holes on the engine casing are matched and positioned, while ensuring that the three end face positioning blocks 8 are positioned and matched with the end face of the engine casing;

[0063] S3: No. 2 oil inlet 19 enters oil, pushes the piston rod 6 to move downward, the lower limit block 605 of the head of the piston rod 6 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com