Bakelite poured mould

A mold and bakelite technology, applied in the chemical industry, can solve problems such as material waste, achieve the effect of reducing heat conduction and preventing curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

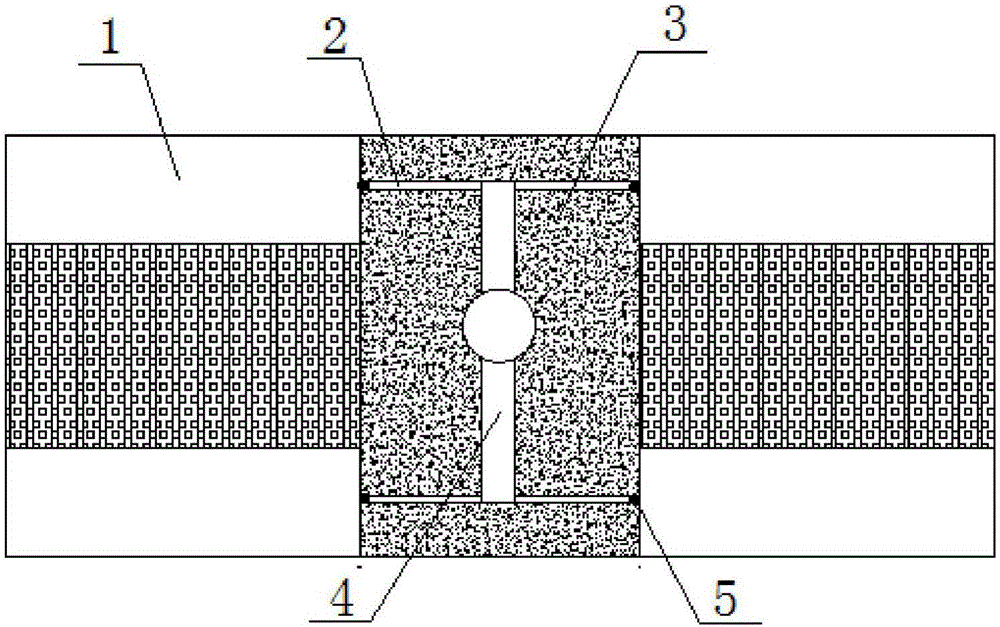

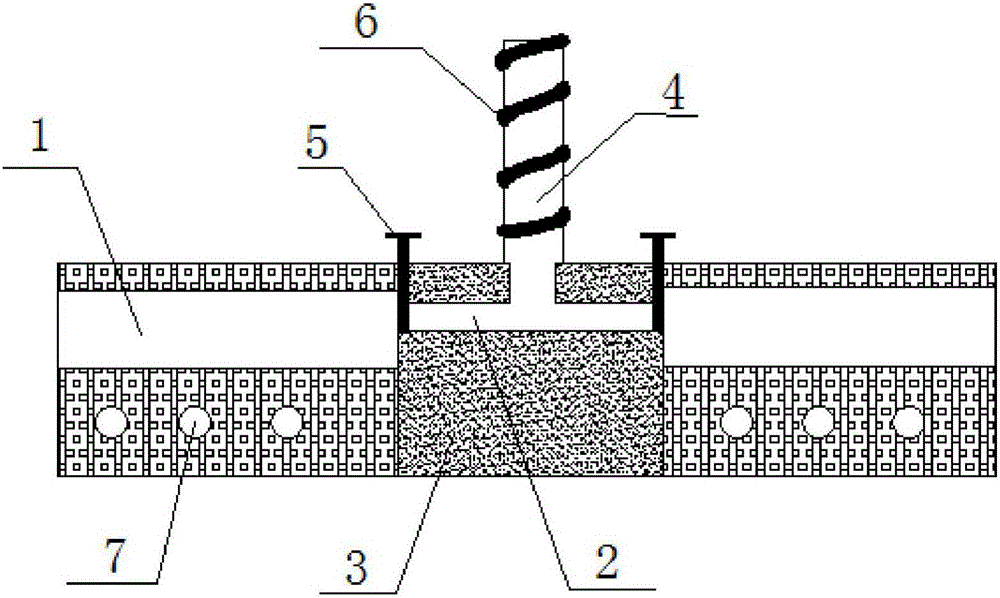

[0018] A bakelite pouring mold, including a pouring system 4, a runner 2 connected to the outlet of the pouring system 4, and a cavity 1 connected to the outlet of the runner 2, the runner 2 is set in the heat insulation material 3, and the pouring system 4 is set There is a first heating device, and the cavity is provided with a second heating device.

[0019] In the present invention, the heat insulating material 3 is used to make the flow channel 2 of the mold, and the temperature of the flow channel 2 is controlled at 75-85°C through an independent first heating device, and the temperature in the cavity 1 is controlled at 160°C through an independent second heating device. -180°C, due to the effect of the heat insulating material, it can prevent the high temperature of the cavity 1 from solidifying the material in the flow channel 2 through heat conduction, so that the material in the flow channel 2 is always at the fluidized state temperature, and the material in the flow ...

Embodiment 2

[0021] This embodiment is further optimized on the basis of embodiment 1, and a mechanical valve 5 is provided between the outlet of the flow channel 2 and the cavity 1 . It is opened during pouring and closed after pouring, which can further reduce the heat conduction at the interface and prevent the phenolic resin in the runner 2 from solidifying.

Embodiment 3

[0023] This embodiment is further optimized on the basis of embodiment 1 or embodiment 2. The first heating device is a heating coil 5 wound on the pouring system 4 . The temperature of the phenolic resin in the flow channel 2 is controlled at 75-85° C. by the heating coil 5 so that it can flow without being solidified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com