Biochemical reagent strip cutting and packing equipment

A technology for packaging equipment and biological reagents, applied in the field of biological reagent strip cutting and packaging equipment, can solve the problems of NC film scratches, production troubles, high labor costs, etc., and achieve the effect of saving manpower and costs and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

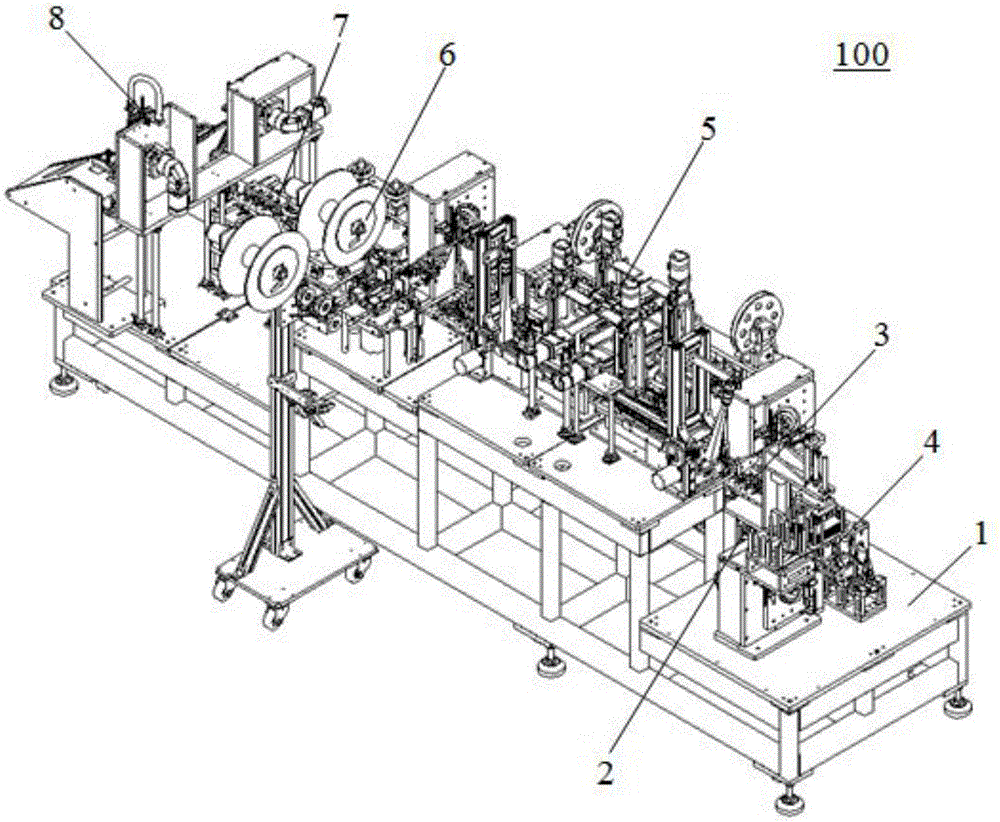

[0050] Please refer to Figure 1-Figure 16 , the present embodiment is a biological reagent strip cutting and packaging equipment 100, which includes a machine platform 1, a prefabricated bag conveying device 2 fixed on the machine platform 1, a bag opening device 3 fixed at the front end of the prefabricated bag conveying device 2, along The prefabricated bag conveying device 2 is sequentially provided with a prefabricated bag feeding and on-line device 4 , a reagent strip feeding and cutting device 5 , a desiccant feeding and cutting device 6 , a bag sealing device 7 and an output device 8 .

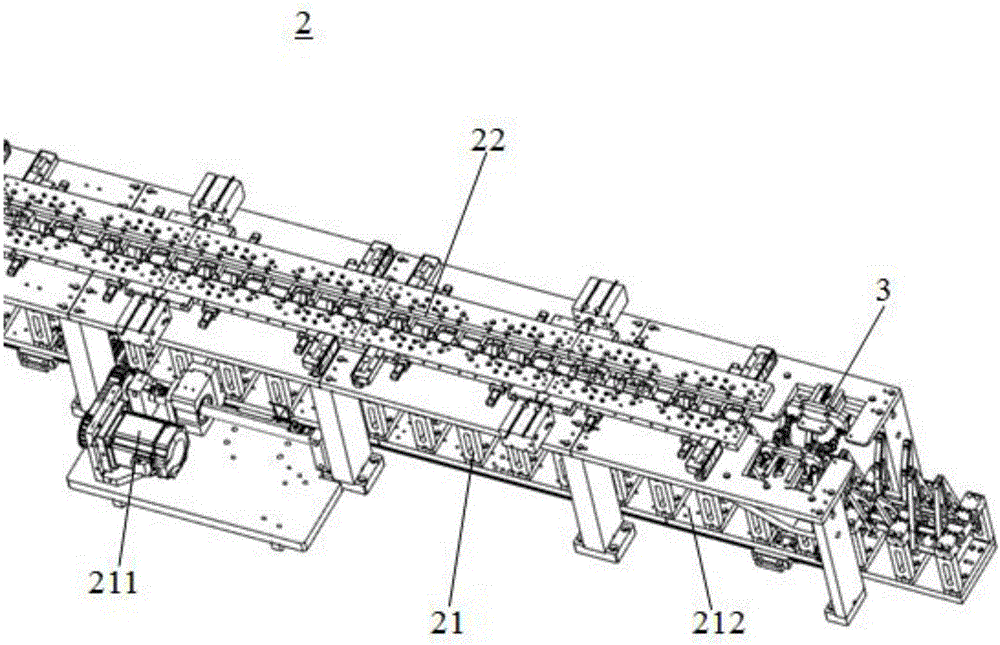

[0051] The prefabricated bag conveying device 2 includes a clamping conveying device 21 located below the machine 1 and a clamping device 22 located above the clamping conveying device 21 . The clamping conveying device 21 and the clamping device 22 run through from one end of the device to the other end.

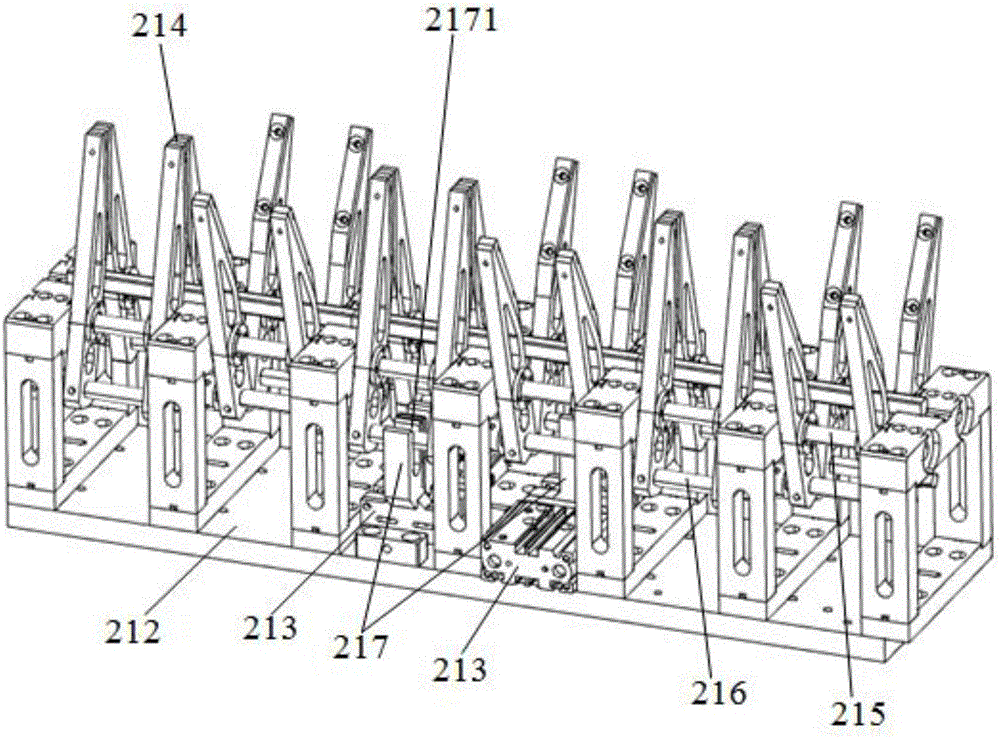

[0052]The clamping and conveying device 21 includes a first driving member 211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com