Granular food crop long-distance screw type pneumatic transportation system

A pneumatic conveying system and crop technology, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of limited use range, waste of materials, manpower and energy, broken bags, bulk leakage, etc., to improve dehumidification and drying effect, good drying effect, easy handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

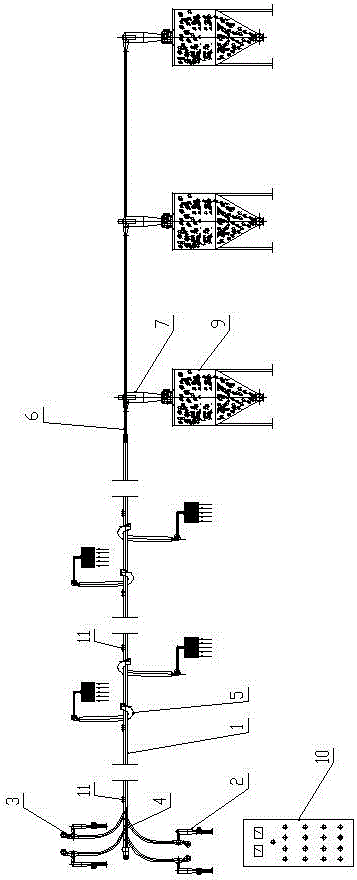

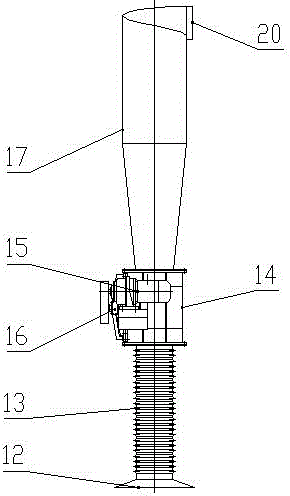

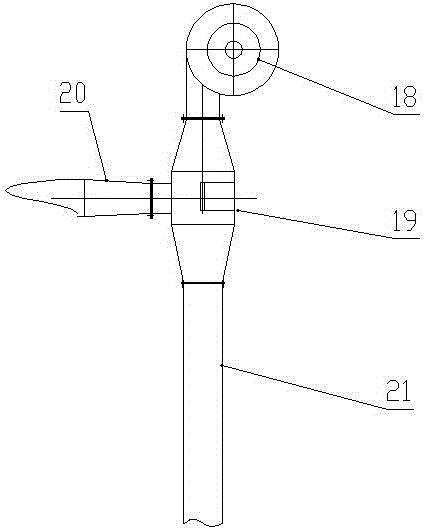

[0039] like Figure 1-Figure 8 As shown, the long-distance spiral pneumatic conveying system for granular food crops of the present invention includes a main conveying pipe 1, a connecting suction device 2, a gas-solid two-phase flow forming device 3, a mechanical spiral flow swirling device 4, and a pneumatic Spiral flow enhancement device 5, diversion device 6, gas-solid separation device 7, storage warehouse 9 and automatic control and monitoring system.

[0040] The discharge port of the suction device 2 is connected to the feed port of the gas-solid two-phase flow forming device 3, and the discharge port of the gas-solid two-phase flow forming device 3 is connected to the feed port of the main conveying pipeline 1, mechanically The spiral flow swirling device 4 is arranged at the feed inlet of the main material conveying pipeline 1, and several pneumatic spiral flow enhancing devices 5 are arranged at regular intervals along the conveying direction of the material conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com