Integrated A2O improvement system

A technology of aerobic zone and secondary sedimentation tank, which is applied in A2O and oxidation ditch to improve A2O in an integrated way. ,A2O combined with the oxidation ditch field can solve the problems of high investment and operating costs, low impact load resistance, and unfavorable phosphorus removal, and achieve the effect of reducing operating costs, reducing impacts, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

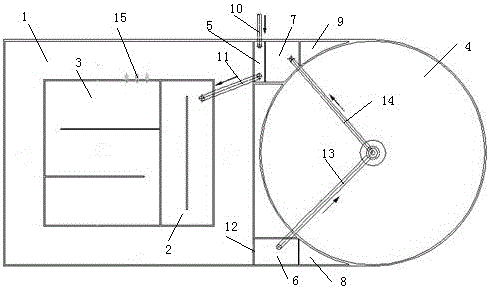

[0012] Embodiment 1: Integrated improvement A 2 O system, including the aerobic zone 1, the aerobic zone 1 is set in an annular ditch structure, the anaerobic zone 2 and the anoxic zone 3 are set in the center of the aerobic zone 1 ring ditch, and the side of the aerobic zone 1 is set with a secondary sedimentation tank 4 , the sandwich area between the secondary settling tank 4 and the aerobic zone 1 is divided into an influent mixing zone 5, a secondary settling tank inflow zone 6, a sludge return zone 7, an effluent zone 8, and a slag clear liquid discharge zone 9. The water pipe 10 is connected to the water inlet mixing area 5, and the water inlet mixing area 5 mixes the water entering the water inlet mixing area 5 with the return sludge transported by the sludge return area 7 through the first pipeline 11 and enters the anaerobic area 2, and the anaerobic area 2 The sewage enters the anoxic zone 3 through holes, and the sewage in the anoxic zone 3 enters the aerobic zone ...

Embodiment 2

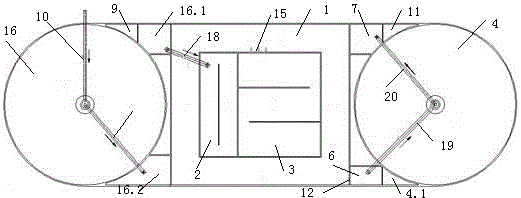

[0013] Embodiment 2: Integrated improvement A 2 O system, including aerobic zone 1, aerobic zone 1 is set in an annular ditch structure, anaerobic zone 2 and anoxic zone 3 are set in the center of the aerobic zone 1 circular ditch, and primary sedimentation tanks are set on both sides of aerobic zone 1 16 and the secondary settling tank 4, the area between the primary settling tank 16 and the aerobic zone 1 is divided into the primary settling tank effluent area 16.1, the primary settling tank sludge discharge area 16.2, the slag clear liquid discharge area 9, and the secondary settling tank 4 and the aerobic zone 1 are divided into secondary settling tank outlet area 4.1, slag liquid discharge area 9, sludge return area 7, secondary settling tank inlet area 6, and water inlet pipe 10 connected to the primary settling tank 16. The sludge produced in the primary sedimentation tank 16 enters the sludge discharge area 16.2 of the primary sedimentation tank through the fourth pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com