Early strength polycarboxylic acid type water reducer, as well as preparation method and application thereof

A technology of polycarboxylate and water reducer, which is applied in the field of building materials, can solve the problems of poor comprehensive performance of early-strength polycarboxylate water reducer, adverse effects on the strength of concrete in the later stage, long initial setting time and final setting time, etc. Achieve uniform and stable storage, improve durability and good flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

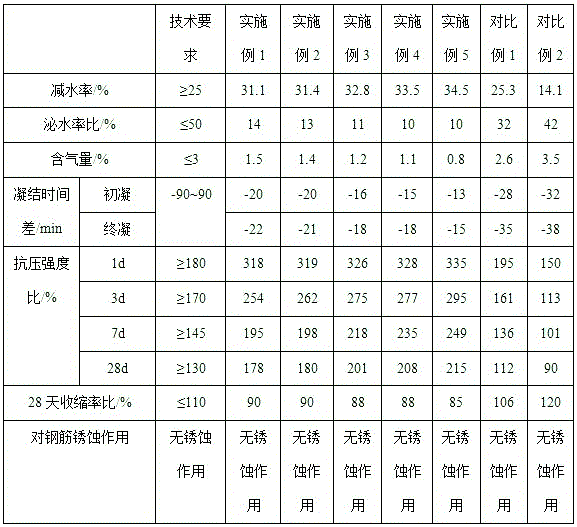

Examples

Embodiment 1

[0016] In the embodiment of the present invention, an early-strength polycarboxylate water-reducing agent is composed of the following raw materials in parts by weight: 25 parts of acrylic acid, 7 parts of sea sand, 12 parts of polyethyleneimine, and 1 part of polysorbate.

[0017] The polyethyleneimine solution was prepared by mixing polyethyleneimine and its mass 3.3 times of 75% ethanol. Mix the sea sand with the polyethyleneimine solution, and stir for 35min at 88°C, then add polysorbate, heat up to 105°C, and stir at this temperature for 28min, add acrylic acid, and heat at 74°C. Ultrasonic treatment at temperature for 45min, ultrasonic power is 1000W, then centrifugation at 3000r / min for 10min, taking the filtrate, and stirring at 85℃ for 15min to obtain polycarboxylate water reducing agent.

Embodiment 2

[0019] In the embodiment of the present invention, an early-strength polycarboxylate water-reducing agent is composed of the following raw materials in parts by weight: 35 parts of acrylic acid, 15 parts of sea sand, 20 parts of polyethyleneimine, and 5 parts of polysorbate.

[0020] The polyethyleneimine solution was prepared by mixing polyethyleneimine and its mass 3.3 times of 75% ethanol. Mix the sea sand with the polyethyleneimine solution, and stir for 40min at 88°C, then add polysorbate, heat up to 105°C, and stir at this temperature for 28min, add acrylic acid, and heat at 74°C. Ultrasonic treatment at temperature for 45min, ultrasonic power is 1000W, then centrifugation at 3000r / min for 10min, taking the filtrate, and stirring at 85℃ for 15min to obtain polycarboxylate water reducing agent.

Embodiment 3

[0022] In the embodiment of the present invention, an early-strength polycarboxylate water-reducing agent is composed of the following raw materials in parts by weight: 28 parts of acrylic acid, 9 parts of sea sand, 14 parts of polyethyleneimine, and 2 parts of polysorbate.

[0023] The polyethyleneimine solution was prepared by mixing polyethyleneimine and its mass 3.3 times of 75% ethanol. Mix the sea sand and polyethyleneimine solution, and stir for 38min at 88°C, then add polysorbate, heat up to 105°C, and stir at this temperature for 28min, add acrylic acid, and heat at 74°C. Ultrasonic treatment at temperature for 45min, ultrasonic power is 1000W, then centrifugation at 3000r / min for 10min, taking the filtrate, and stirring at 85℃ for 15min to obtain polycarboxylate water reducing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com