Flame-retardant headband material

A headband and accelerant technology, which is applied in the field of gas mask cover body accessories, can solve the problems of poor flame retardancy and achieve reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

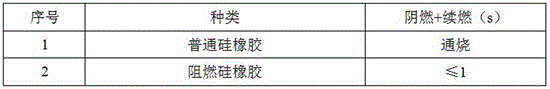

Image

Examples

Embodiment 1

[0028] A flame retardant headband material comprising the following components by weight:

[0029] 70 parts of natural rubber, 15 parts of neoprene, 10 parts of zinc oxide, 10 parts of magnesium oxide, 5 parts of stearic acid, 2 parts of sulfur, 2 parts of accelerator DM, 4 parts of accelerator M, 3 parts of accelerator NA-22, 50 parts of decabromodiphenyl ether, 35 parts of antimony trioxide, 2 parts of antioxidant D, 1 part of antioxidant MB, 30 parts of clay, 15 parts of calcium carbonate, 5 parts of carbon black N220.

[0030] The preparation method is as follows:

[0031] XK-160mm open type rubber mixing machine is used for compounding rubber, and the speed ratio of the rollers is 1:1.25; the temperature of the front roller is 50°C when the silicone rubber is mixed, and the temperature of the rear roller is slightly higher, which is 65°C; the mixing process is as follows :

[0032] (1) Adjust the roller distance to 0.1, add natural rubber, make it wrap the front roller,...

Embodiment 2

[0041] A flame retardant headband material comprising the following components by weight:

[0042] 80 parts of natural rubber, 30 parts of neoprene, 10 parts of zinc oxide, 2 parts of magnesium oxide, 10 parts of stearic acid, 8 parts of sulfur, 1 part of accelerator DM, 2 parts of accelerator M, 1 part of accelerator NA-22 , 25 parts of decabromodiphenyl ether, 40 parts of antimony trioxide, 5 parts of antioxidant D, 2 parts of antioxidant MB, 35 parts of clay, 10 parts of calcium carbonate, and 15 parts of carbon black N220.

[0043] The preparation method is as follows:

[0044] XK-160mm open-type rubber mixing machine is used for mixing rubber materials, and the speed ratio of the rollers is 1:1.25; when mixing silicone rubber, the temperature of the front roller is 55°C, and the temperature of the rear roller is slightly higher, which is 65°C; the mixing process is as follows :

[0045] (1) Adjust the roller distance to 0.1, add natural rubber, make it wrap the front ro...

Embodiment 3

[0054] A flame retardant headband material comprising the following components by weight:

[0055] 90 parts of natural rubber, 10 parts of neoprene, 5 parts of zinc oxide, 8 parts of magnesium oxide, 2 parts of stearic acid, 10 parts of sulfur, 3 parts of accelerator DM, 1 part of accelerator M, 2 parts of accelerator NA-22 , 20 parts of decabromodiphenyl ether, 15 parts of antimony trioxide, 1 part of antioxidant D, 5 parts of antioxidant MB, 50 parts of clay, 5 parts of calcium carbonate, and 12 parts of carbon black N220.

[0056] The preparation method is as follows:

[0057] XK-160mm open type rubber mixing machine is used for compounding rubber, and the speed ratio of the rollers is 1:1.25; the temperature of the front roll is 50°C when the silicone rubber is mixed, and the temperature of the rear roll is slightly higher, 60°C; the mixing process is as follows :

[0058] (1) Adjust the roller distance to 0.1, add natural rubber, make it wrap the front roller, and masti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com