A kind of track rubber pad material and preparation method thereof

A technology of rubber pads and rails, applied in the field of rail transportation, can solve the problems of low damping coefficient, i.e. low loss factor, and regulations on damping performance of rubber pads, and achieve the effect of excellent damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

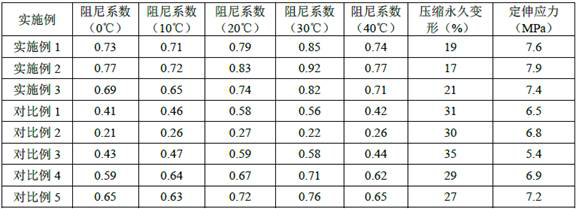

Examples

Embodiment 1

[0032] A rail rubber pad material, which is composed of the following raw material ratios (in parts by weight): 90 parts of nitrile rubber, 10 parts of the organic polymer prepared in Example 1, 5 parts of zinc oxide, 1.5 parts of stearic acid, and carbon black 30 parts, 20 parts of light calcium carbonate, 30 parts of Sabofi, 10 parts of white carbon black, 5 parts of paraffin oil, 2 parts of protective wax, 1 part of antioxidant RD, 1 part of antioxidant 4010NA, 1 part of antioxidant 4020, dispersed 2 parts of PEG4000, 1.4 parts of sulfur, 1.3 parts of accelerator CZ, 0.3 part of accelerator TMTD, 0.8 part of accelerator DM, 0.5 part of anti-scorch agent CTP, and 5 parts of calcium oxide.

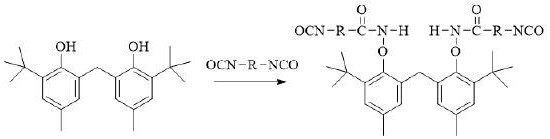

[0033] The organic polymer is prepared by the following method:

[0034] Add isocyanate and 2,2'-methylene bis(4-methyl-6-tert-butylphenol) into a four-necked flask with a mechanical stirring bar and a thermometer in a molar ratio of 2:1, and add 0.02% Dibutyltin dilaurate, heat up to 95...

Embodiment 3

[0042] Example 3 Track rubber pad material

[0043] A rail rubber backing plate material, which is composed of the following raw material ratios (in parts by weight): 85 parts of nitrile rubber, 15 parts of the organic polymer prepared in Example 1, 5 parts of zinc oxide, 2 parts of stearic acid, and carbon black 35 parts, 20 parts of light calcium carbonate, 40 parts of Sabofi, 10 parts of white carbon black, 6 parts of paraffin oil, 3 parts of protective wax, 1 part of antioxidant RD, 1 part of antioxidant 4010NA, 1 part of antioxidant 4020, dispersed 1 part of PEG4000, 1.2 part of sulfur, 1.5 part of accelerator CZ, 0.4 part of accelerator TMTD, 0.6 part of accelerator DM, 0.5 part of anti-scorch agent CTP, and 5 parts of calcium oxide.

[0044] The organic polymer is prepared by the following method:

[0045] Add isocyanate and 2,2'-methylene bis(4-methyl-6-tert-butylphenol) into a four-necked flask with a mechanical stirring bar and a thermometer in a molar ratio of 2:1,...

Embodiment 4

[0054] A rail rubber pad material, which is composed of the following raw material ratios (in parts by weight): 95 parts of nitrile rubber, 5 parts of the organic polymer prepared in Example 1, 5 parts of zinc oxide, 2 parts of stearic acid, and carbon black 35 parts, 20 parts of light calcium carbonate, 40 parts of Sabofi, 10 parts of white carbon black, 6 parts of paraffin oil, 3 parts of protective wax, 1 part of antioxidant RD, 1 part of antioxidant 4010NA, 1 part of antioxidant 4020, dispersed 1 part of PEG4000, 1.2 part of sulfur, 1.5 part of accelerator CZ, 0.4 part of accelerator TMTD, 0.6 part of accelerator DM, 0.5 part of anti-scorch agent CTP, and 5 parts of calcium oxide.

[0055] The organic polymer is prepared by the following method:

[0056] Add isocyanate and 2,2'-methylene bis(4-methyl-6-tert-butylphenol) into a four-necked flask with a mechanical stirring bar and a thermometer in a molar ratio of 2:1, and add 0.02% Dibutyltin dilaurate, heat up to 95°C, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com