Vinasse cooler

A technology of air-drying machine and fan, which is applied in the field of wine making, can solve the problems of large temperature differences between the surface and the bottom, achieve better cooling effect, obvious effect, and avoid large temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific examples, but the implementation of the present invention is not limited thereto.

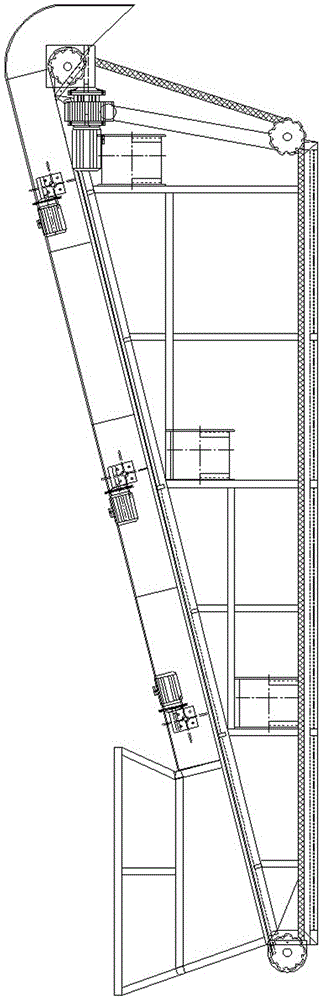

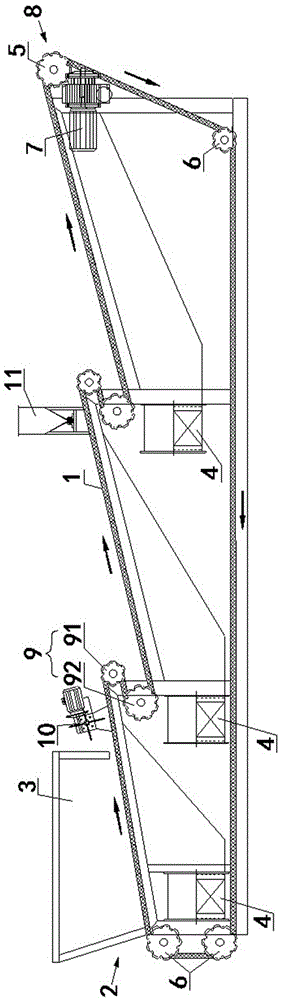

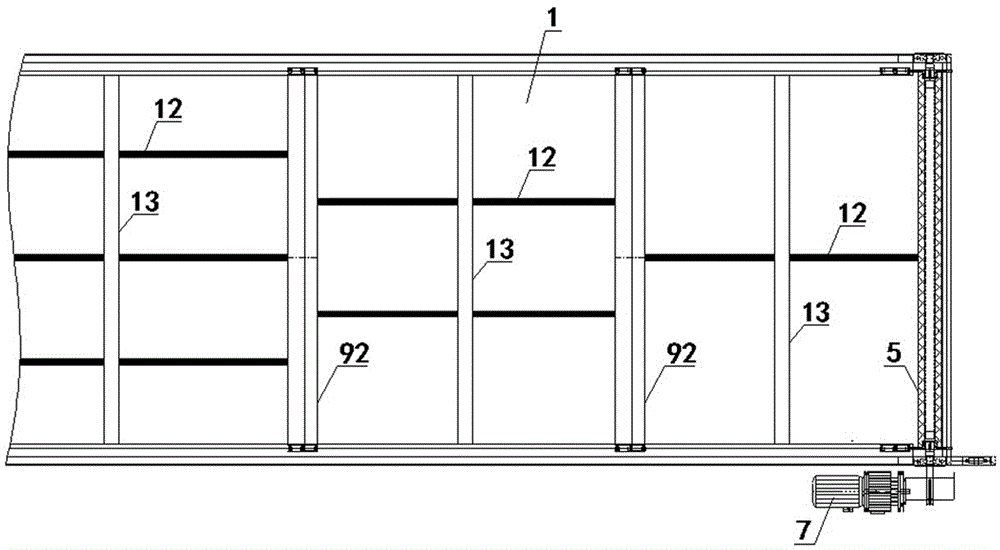

[0017] Such as figure 2 As shown, the bad drying machine of the present invention includes a conveying chain plate 1, a feeding hopper 3 and a blower fan 4. The conveying chain plate 1 is provided with several ventilation holes, the conveying chain plate 1 is installed on a driving wheel 5 and a plurality of driven wheels 6, the driving wheel 5 is driven by a motor 7 through a reducer, and the feeding of the conveying chain plate 1 A feeding hopper 3 is arranged on the side, and a stirring shaft 10 is arranged at the outlet of the feeding hopper 3. A number of steel claws are arranged on the stirring shaft 10 for breaking up the distiller's grains. The material side 8 is divided into three sections by two sets of segmentation mechanisms 9, each section of the conveying chain plate 1 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com