Modular high-performance soft steel lead-core rubber energy dissipater

A technology of lead-core rubber and lead-core rubber bearings, which is applied in the field of modular high-performance mild steel lead-rubber energy dissipators, can solve the problems of single energy consumption principle, increase energy consumption efficiency, and improve pressure stability , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

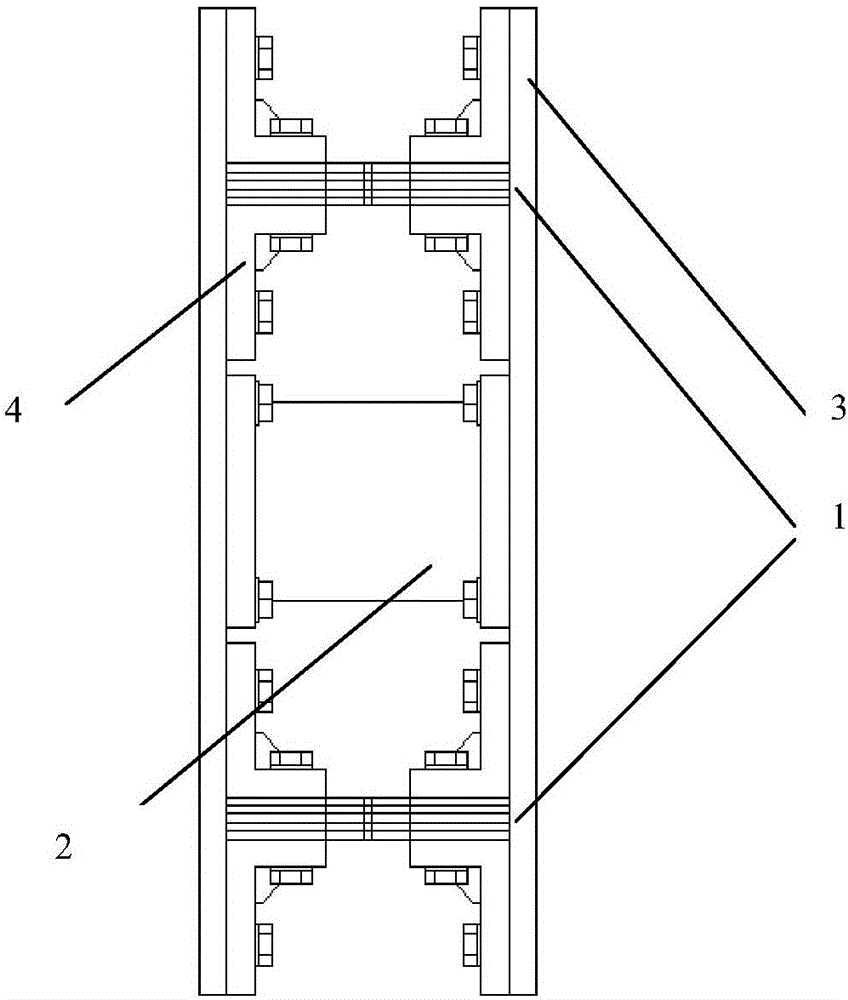

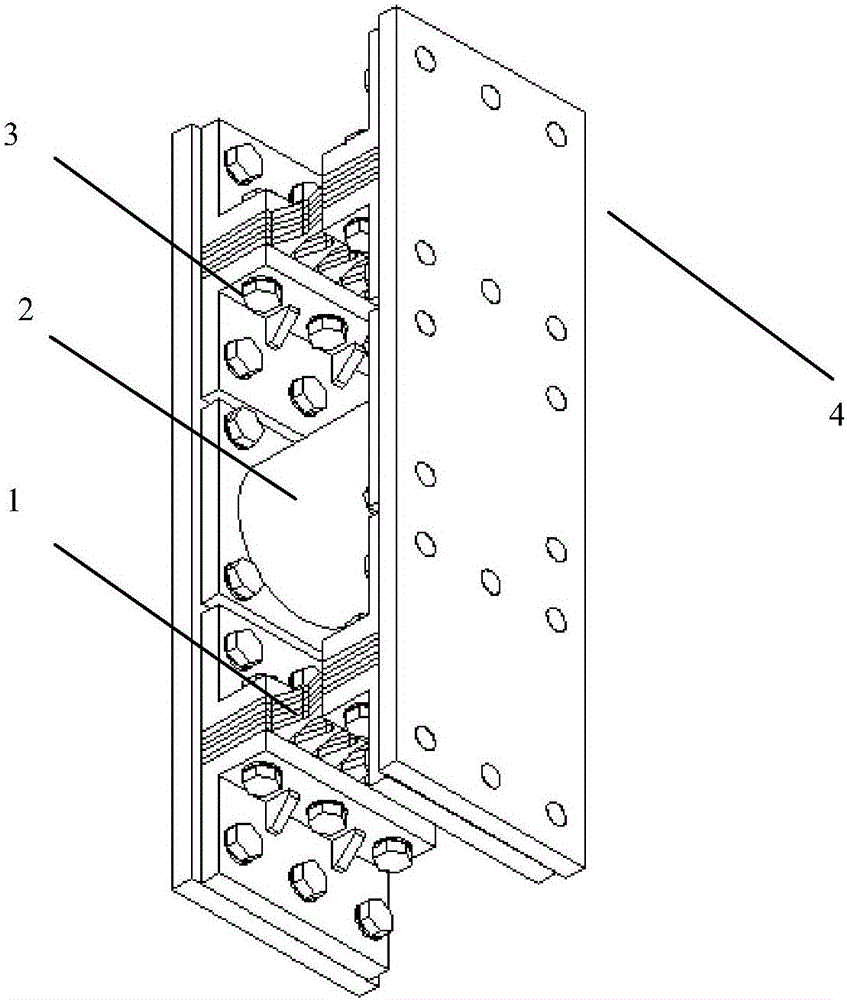

[0028] Modular high-performance mild steel lead rubber energy dissipator, including two fixed plates 4, lead rubber support 2, and energy dissipation components arranged on both sides of the lead rubber support; the energy dissipation component is composed of multiple mild steel The two ends of a plurality of soft steel sheets 1 are fixed on the fixed plate 4 by a pair of L-shaped splints 3, and the two ends of the lead rubber bearing 2 are also fixed on the fixed plate 4.

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that the mild steel sheets are made of steel with low yield strength, and the multiple mild steel sheets are clamped by a pair of L-shaped splints 3 and bolts passing through them, and fixed by the bolts. The plates 4 are connected, and a plurality of mild steel sheets are tightly fitted. This setting makes the distribution of internal force more uniform under earthquake action, which is beneficial to avoiding the first failure of individual mild steel sheets due to excessive local stress, which will seriously weaken the bearing capacity and energy dissipation capacity of the entire energy dissipation component.

Embodiment 3

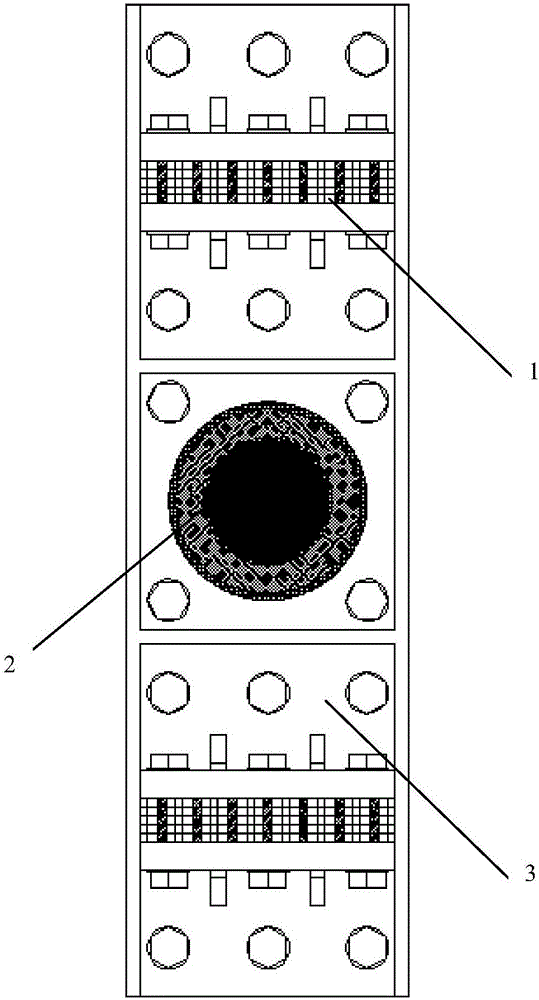

[0032] The difference between this embodiment and Embodiment 2 is that the middle part of the mild steel sheet is an energy-dissipating part, on which a plurality of diamond-shaped holes are arranged, and the energy-dissipating part forms a continuous X-shaped steel sheet. The effective width of the energy-dissipating section of the mild steel sheet increases linearly from the middle to both sides. In order to avoid stress concentration in the middle of the mild steel sheet, a certain effective width remains unchanged in a small area in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com