Wear-resisting solid wood core floor and production technology thereof

A solid wood core, wear-resistant technology, applied in floor coverings, layered products, wood layered products, etc., can solve the problems of variable solid wood flooring, unsightly color difference, and difficulty in fire prevention, so as to reduce scrap rate and improve tightness Solidity, strengthen the effect of crack damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

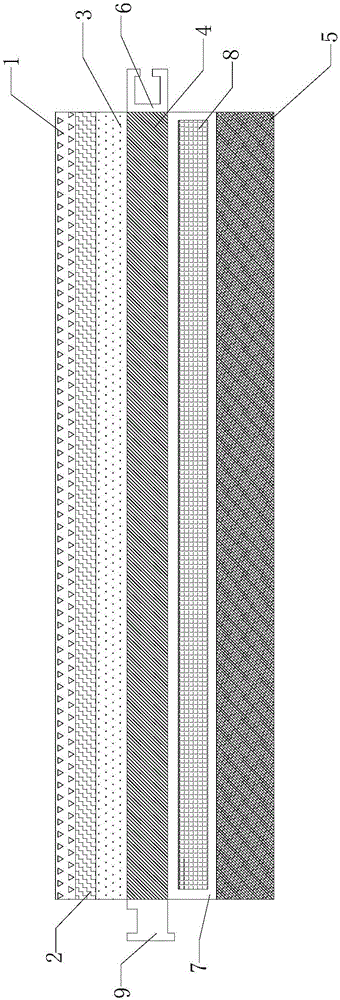

[0034] This embodiment provides a wear-resistant solid wood core floor, comprising a paint layer 1, a wear-resistant layer 2, a decorative layer 3, a substrate layer 4 and a core layer 5, the upper surface of the decorative layer 3 and the lower surface of the wear-resistant layer 2 connected, the upper surface of the wear-resistant layer 2 is coated with a paint layer 1, the lower surface of the wear-resistant layer 2 is connected with the upper surface of the decorative layer 3, and the lower surface of the decorative layer 3 is connected with the upper surface of the substrate layer 4, The lower surface of the base material layer 4 is connected with the core layer 5, one side of the base material layer 4 is provided with a fixing groove 6, and the other side is provided with a protrusion 9 matched with the fixing groove, the base material layer 4 and the core layer 5 There is a steel channel 7 between them, and the steel channel 7 is filled with moisture-proof silicone rubbe...

Embodiment 2

[0050] This embodiment provides a wear-resistant solid wood core floor, comprising a paint layer 1, a wear-resistant layer 2, a decorative layer 3, a substrate layer 4 and a core layer 5, the upper surface of the decorative layer 3 and the lower surface of the wear-resistant layer 2 connected, the upper surface of the wear-resistant layer 2 is coated with a paint layer 1, the lower surface of the wear-resistant layer 2 is connected with the upper surface of the decorative layer 3, and the lower surface of the decorative layer 3 is connected with the upper surface of the base material layer 4, The lower surface of the base material layer 4 is connected with the core layer 5, one side of the base material layer 4 is provided with a fixing groove 6, and the other side is provided with a protrusion 9 matched with the fixing groove, the base material layer 4 and the core layer 5 There is a steel channel 7 between them, and the steel channel 7 is filled with moisture-proof silicone r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com